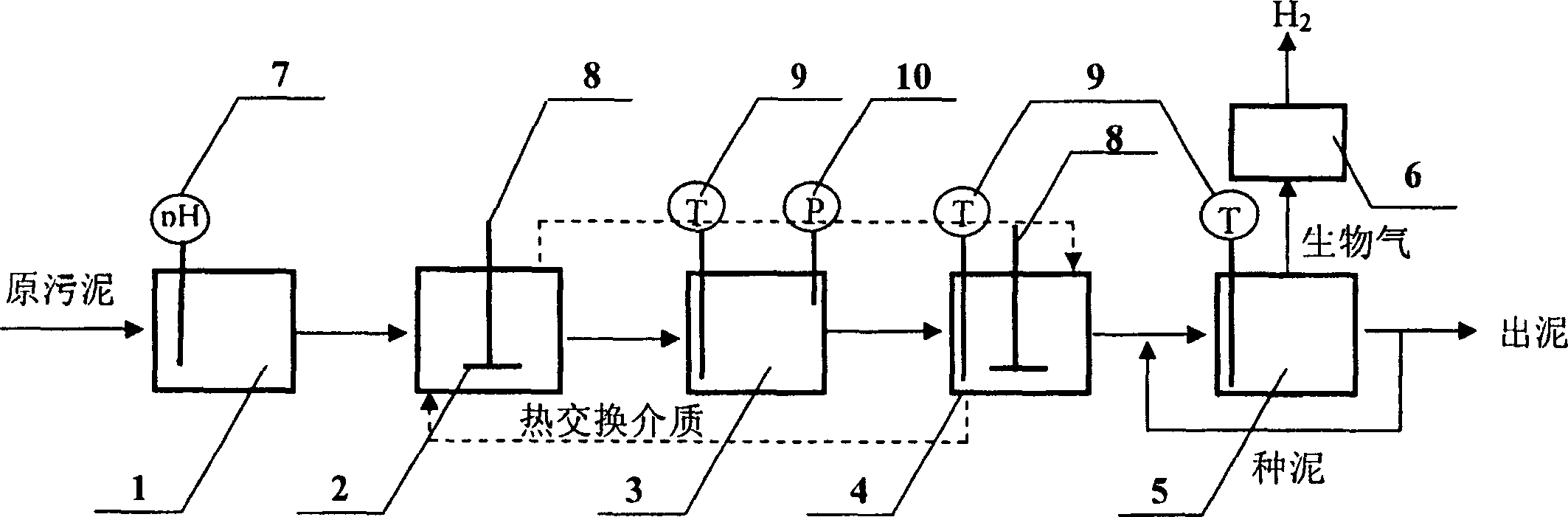

Heat treatment-fermented hy drogen-generating method by preparing hydrogen from residual sludge for sewage treatment plant

A technology for sewage treatment plants and excess sludge, applied in water/sludge/sewage treatment, hydrogen production, sludge treatment, etc., to achieve the effects of improved dehydration, reduced sludge volume, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Adjust the excess sludge from the sewage treatment system to DS 9.93g / L (VS 6.23g / L), pretreat it at 80°C and 1 standard atmospheric pressure (atm) for 1 hour, and then cool it to 50-60 at room temperature. ℃, use a mechanical stirrer to stir the thermally pretreated sludge evenly, take 150ml of pretreated sludge and add it to a 310ml anaerobic fermentation tank, use high-purity nitrogen (99.99%) to bubble the sludge for 2 minutes, replace and remove Oxygen in the gas phase and liquid phase of the fermenter, then sealed, placed in an air bath shaker, kept in the dark with stirring (140-150 rpm × 37.0 ± 1.0 ° C). The maximum concentration of hydrogen in the biohydrogen obtained after anaerobic fermentation reaches 50.2%, and methane is also not detected in the biogas. The hydrogen production of sludge reached the maximum (7.67ml / gVS) at about 17 hours, after which hydrogen consumption occurred.

Embodiment 2

[0027] The concentration of the excess sludge was adjusted to DS 11.71g / L (VS 7.81g / L), pretreated at 121°C and 1.5 standard atmospheric pressure (atm) for 0.5 hour, and the operation thereafter was the same as in Example 1. The maximum concentration of hydrogen in the biogas obtained after anaerobic fermentation was 47.0%, and the presence of methane was not detected. The hydrogen production rate of the sludge reached the maximum (19.42ml / gVS) at about 32 hours, and then due to the growth of hydrogen-consuming bacteria, the hydrogen in the gas phase of the fermenter began to be consumed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com