Prepn process of extreme ultraviolet and soft X-ray filtering metal film

A filter film and X-ray technology, applied in metal material coating process, sputtering coating, ion implantation coating and other directions, can solve problems such as film defects, achieve the effect of low cost, easy storage and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

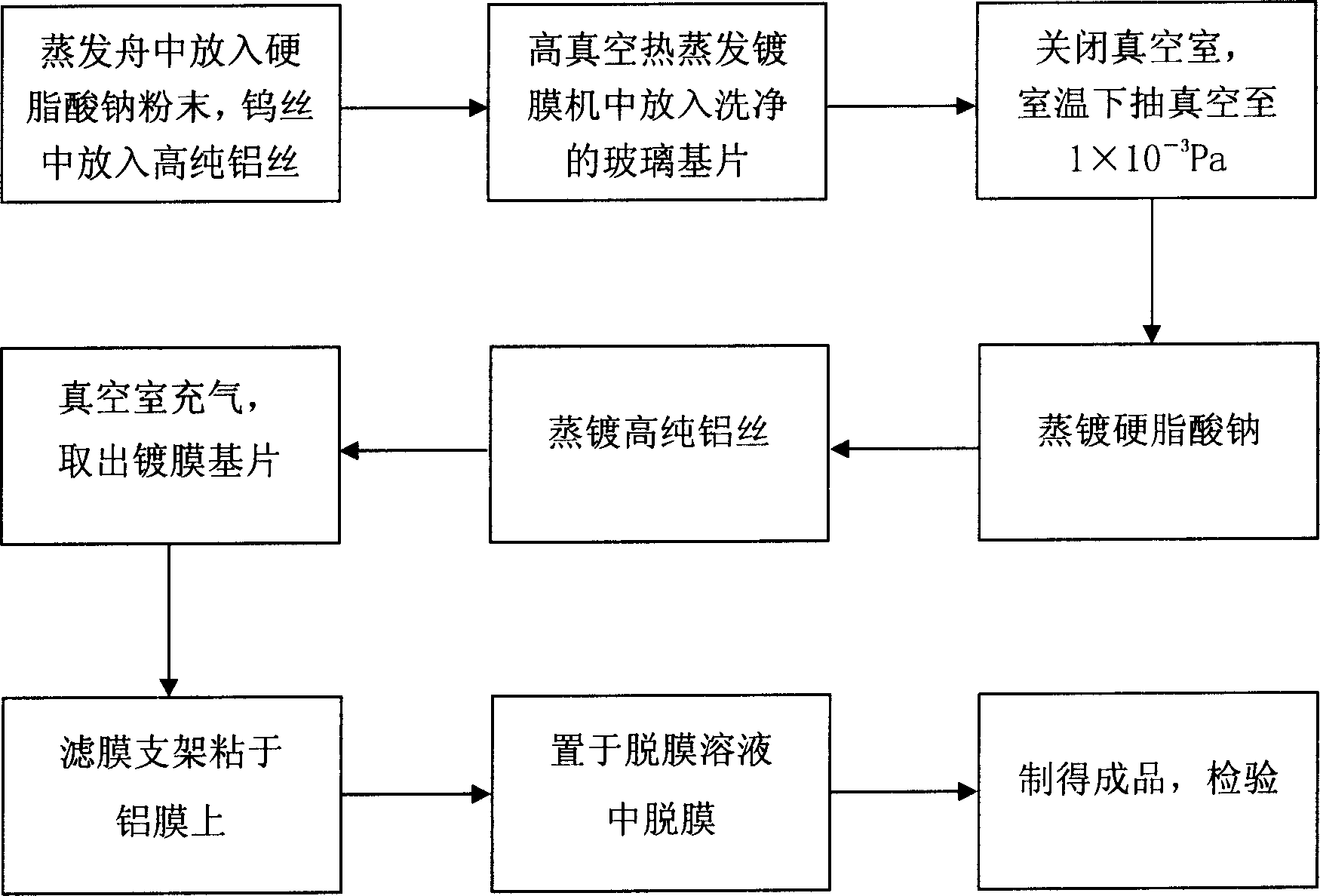

[0019] Please refer to the preparation method flowchart of the preparation method of extreme ultraviolet and soft X-ray metal filter film of the present invention, the embodiment of the present invention is in vacuum chamber pressure 1 * 10 -3 Pa, carried out at room temperature. Use a high-vacuum thermal evaporation coating machine, use sodium stearate powder as the raw material of the release agent, and use a constantan-copper thermocouple to monitor the temperature of the molybdenum boat.

[0020] Put an appropriate amount of sodium stearate powder in the evaporating boat (molybdenum boat), put high-purity aluminum wire in the other evaporating boat (tungsten wire), and place the cleaned polished glass substrate about 20cm above the two evaporating boats , using molybdenum boat and tungsten wire resistance heating method to provide evaporation heat.

[0021] Close the vacuum chamber and perform pumping. When the vacuum reaches 1×10 -3 Start evaporation at Pa, first evapo...

Embodiment 2

[0025] Use a high-vacuum thermal evaporation coating machine, use sodium stearate powder as the raw material of the release agent, and use a constantan-copper thermocouple to monitor the temperature of the molybdenum boat.

[0026] Put an appropriate amount of sodium stearate powder in the evaporation boat (molybdenum boat), place the cleaned polished glass substrate at a position about 20 cm above the evaporation boat, and use the molybdenum boat heating method to provide evaporation heat.

[0027] Close the vacuum chamber and carry out pumping until the vacuum degree reaches 1×10 -3 Pa began to vapor-deposit sodium stearate. The thickness of the coating film is controlled by a quartz crystal vibration film thickness controller, the thickness of the sodium stearate film is controlled at 0.2-0.32 μm, and the evaporation is stopped.

[0028] Open the vacuum chamber, take out the coated glass substrate, and place it in a drying cylinder for 2 to 6 days. Take out the glass subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com