Metal-graphite brush

A technology of metal graphite and electric brushes, applied in the direction of circuits, current collectors, electrical components, etc., can solve the problem of reducing the mountability of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

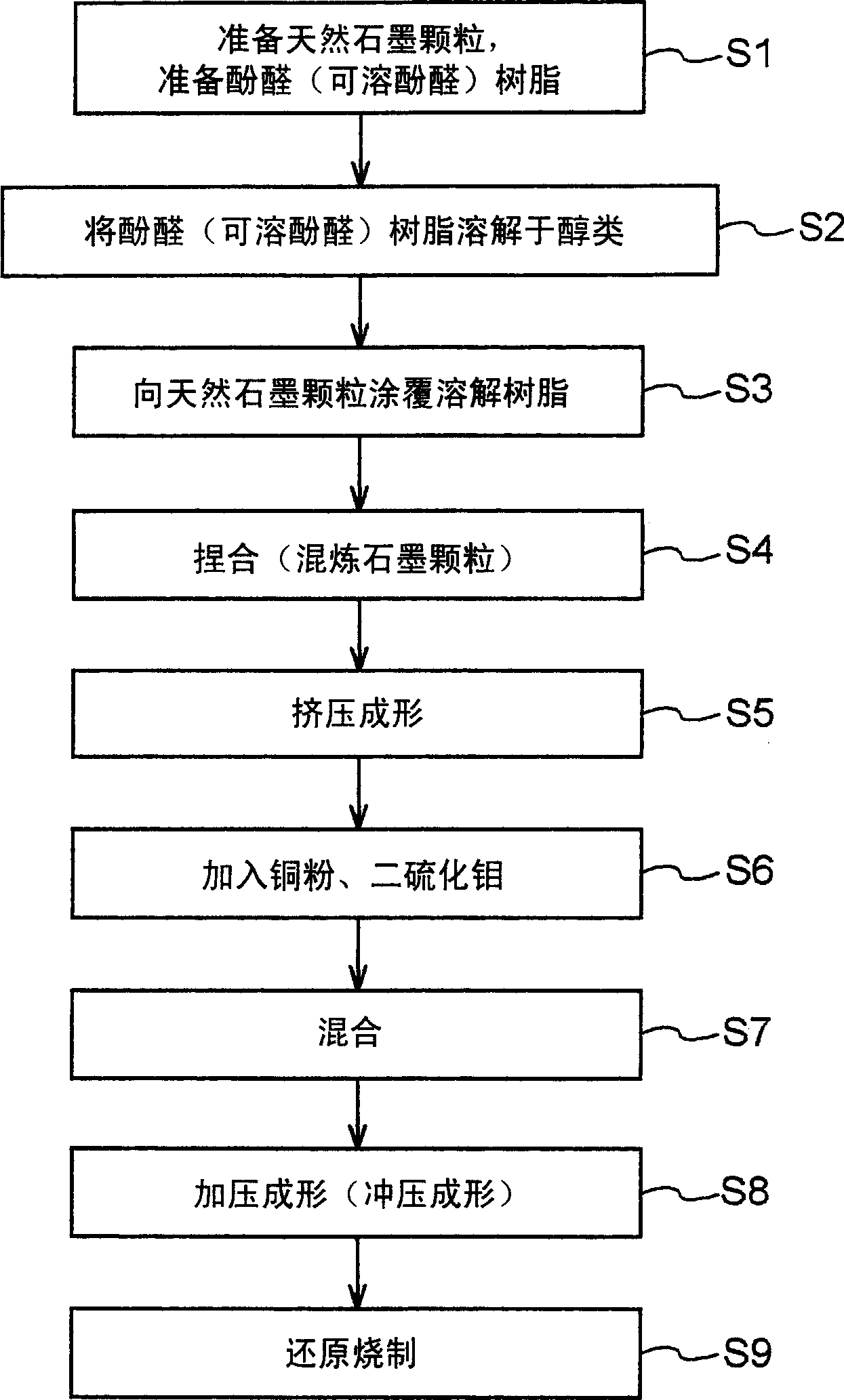

[0080] The case where N,N-diethyl-N-methyl-N-(2-methoxyethyl)imino(trifluoromethylsulfonate) is used as the ionic liquid will be described. The ionic liquid is compatible with the following solvents at a volume ratio of 1:1: chloroform, methanol, ethanol, acetone, tetrahydrofuran, ethyl acetate, dimethylformamide, 1-propanol, 1-butanol alcohol, isoamyl alcohol. In addition, the ionic conductivity has 3×10 -3 A value around S / cm has the highest ion conductivity among ionic liquids.

[0081] In this embodiment, the volume of the ionic liquid is 1, methanol with a volume ratio of 0.2 and 1-butanol with a volume ratio of 0.4 are mixed to obtain an alcoholic solution of the ionic liquid. As the synthetic oil for dispersing the alcohol solution of the ionic liquid, polyalphaolefin is used, and its thermal decomposability and hydrolysis at 250° C. are only 2 to 3%. Its kinematic viscosity is 4cSt at 100°C, 17cSt at 40°C, and 2500cSt at -40°C. The pour point is -70°C. The viscosi...

Embodiment 2

[0085] As impregnating agent 21, a liquid in which methanol was emulsified in polyalphaolefin and then dispersed in fatty acid ester (Example 2) was used, and capric acid was added to methanol in Example 2 at 25°C Potassium to saturation solubility of the liquid.

[0086] The results are shown in Table 2. In Example 2, after 1000 hours of continuous operation, the wear rate of the brush 1 did not change significantly, but in the middle of 2000 hours of operation, the brush 1 was worn and the brush holder was damaged. However, in Example 2, it can be operated continuously for at least 1000 hours under this load condition, and thus can be used for many vehicle-mounted motors 10 .

Embodiment 3

[0087] In Example 3, the effect of increasing the conductivity of the sliding contact surface is obvious. Under this load condition, the brush 1 is still practical even after continuous operation for 3000 hours.

[0088] In addition, in any of the embodiments, the amount of wear is smaller than that of brushes of conventional products.

[0089] Example 2

Example 3

Existing example

Abrasion after 100 hours

0.2mm

0.1mm

0.3mm

Abrasion after 200 hours

0.3mm

0.2mm

0.5mm

Abrasion after 500 hours

0.7mm

0.4mm

2.5mm

Abrasion after 1000 hours

1.5mm

0.8mm

-

Abrasion after 2000 hours

-

1.5mm

-

Abrasion after 3000 hours

-

2.5mm

-

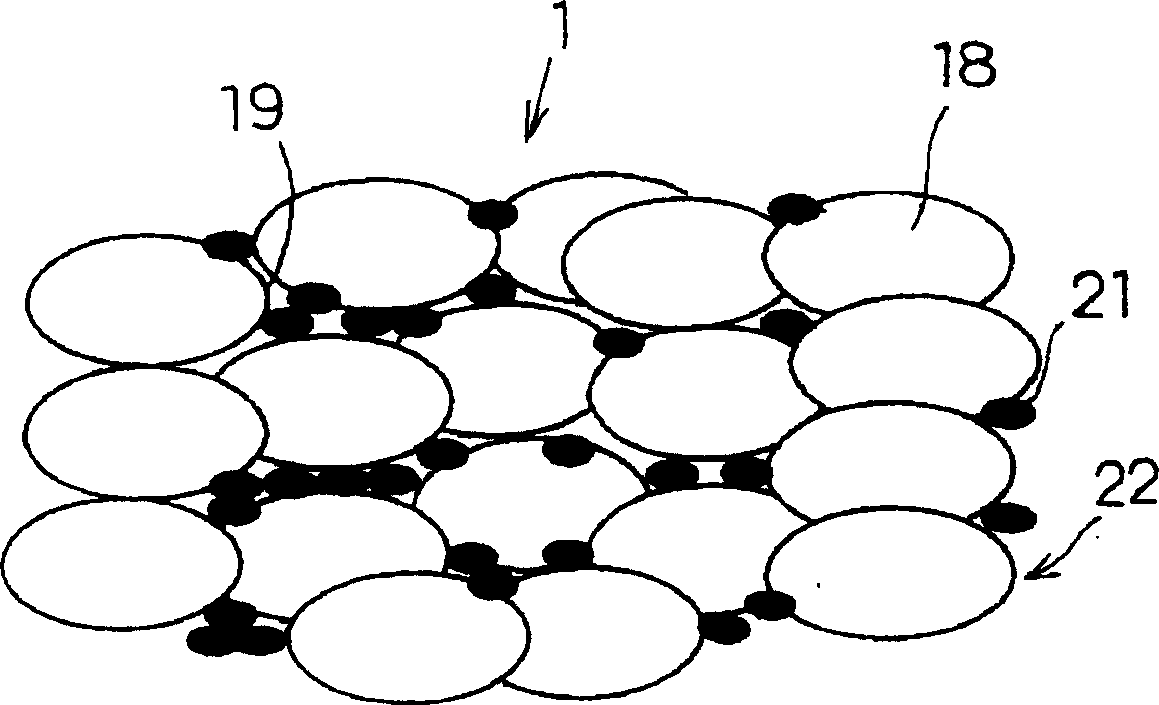

[0090] As described above, by impregnating the entire internal pores 19 of the metal graphite brush 1 of the present invention with the impregnating agent 21 having synthetic oil and conductive liquid, in addition t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com