Process for preparing lactic acid bacteria oral liquor

A technology of lactic acid bacteria oral liquid and strains, applied in the direction of food preparation, medical preparations containing active ingredients, bacteria, etc., to achieve the effect of fast acid production and ideal content of probiotics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

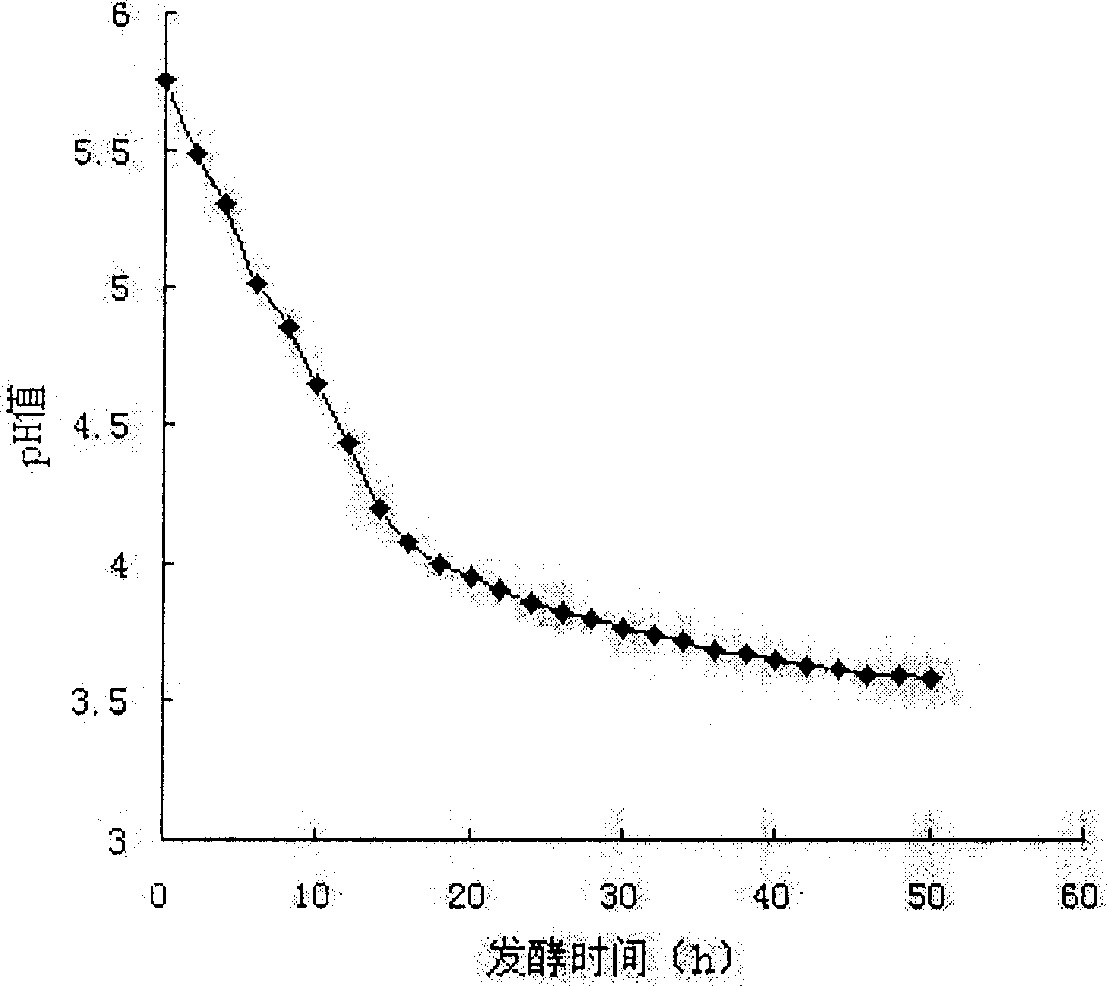

[0023] Embodiment 1: Lactobacillus casei subsp. casei single strain fermentation prepares lactic acid bacteria oral liquid

[0024] In this embodiment, the Lactobacillus casei cheese species is selected for separate fermentation, and the pH value can be reduced to about 3.6 within 48 hours. Preparation method: Mix 2 parts of brown sugar, 5 parts of glucose, 0.2 part of peptone, 0.01 part of magnesium sulfate, 0.01 part of manganese sulfate, 0.01 part of dipotassium hydrogen phosphate, and 0.2 part of sodium chloride, add purified tap water to dissolve, 116 Sterilize by passing steam at ℃; then add 1 part of the seed solution of Lactobacillus casei subspecies cheese, culture at 37℃ for 48 hours, harvest when the pH drops to 3.6, and bottle. Acid production curve see figure 1 . The obtained lactic acid bacteria oral liquid is a brown liquid with a sour taste and a live bacteria content of 1 billion / mL.

Embodiment 2

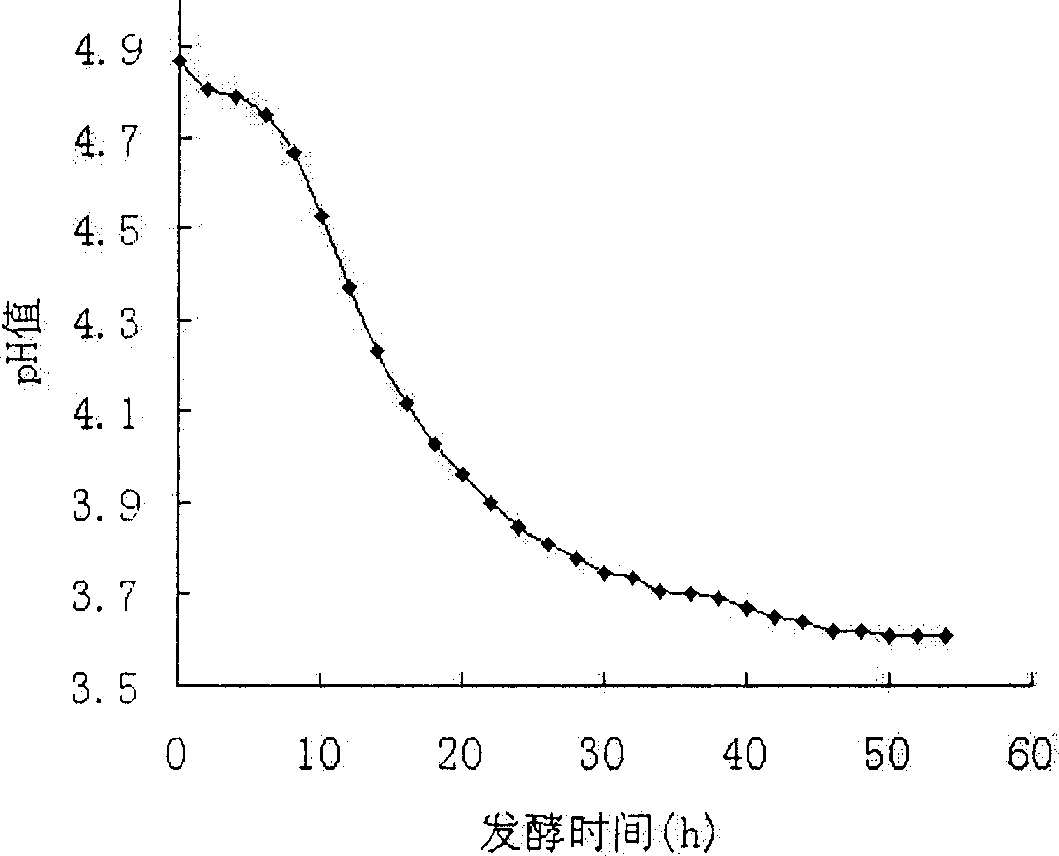

[0025] Example 2: Fermentation of a single strain of Lactobacillus plantarum to prepare lactic acid bacteria oral liquid

[0026] In this embodiment, Lactobacillus plantarum is selected for fermentation alone, and the pH value can be reduced to about 3.7 within 40 hours. Preparation method: Mix 2 parts of brown sugar, 5 parts of glucose, 0.2 part of peptone, 0.01 part of magnesium sulfate, 0.01 part of manganese sulfate, 0.01 part of dipotassium hydrogen phosphate, and 0.2 part of sodium chloride, add purified tap water to dissolve, 116 Sterilize by passing steam at ℃; then inoculate 1 portion of Lactobacillus plantarum seed solution, culture at 37℃ for 48 hours, harvest when the pH drops to 3.6, and bottle. Acid production curve see figure 2 . The obtained lactic acid bacteria oral liquid is a brown liquid with a sour taste and a live bacteria content of 1 billion / mL.

Embodiment 3

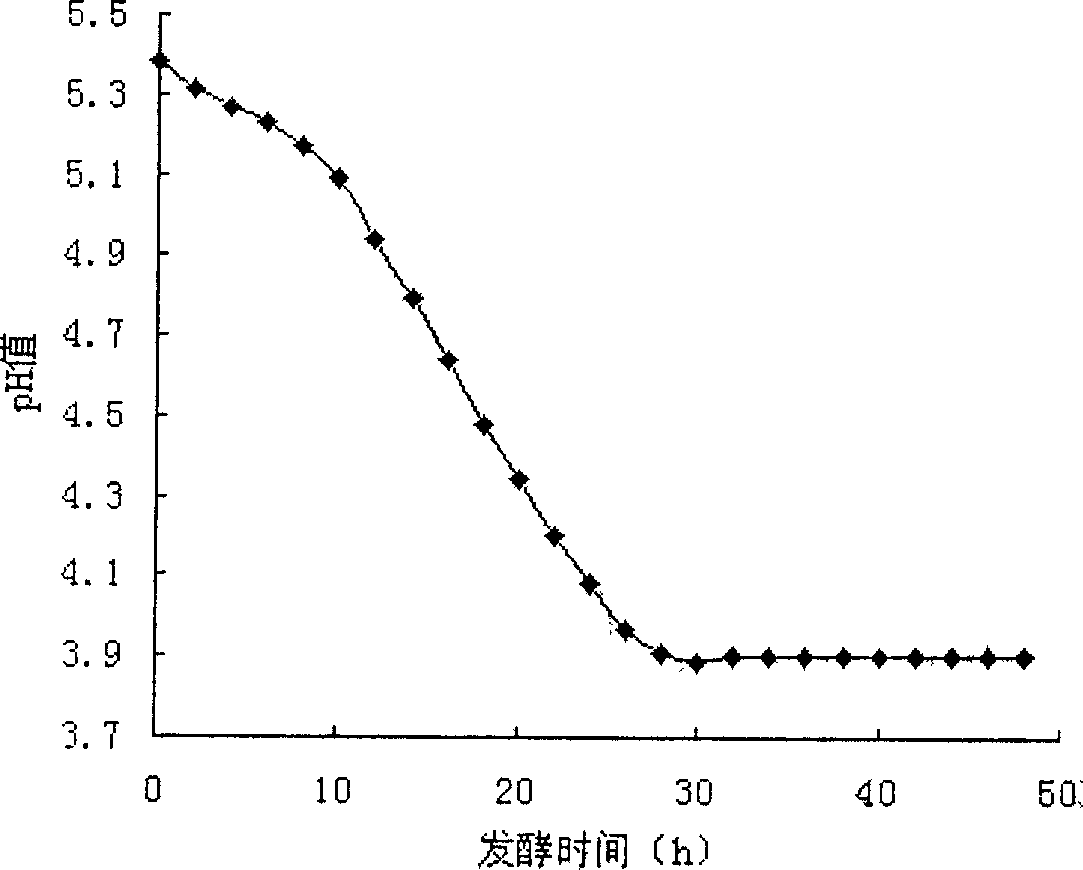

[0027] Example 3: Fermentation of a single strain of Lactobacillus acidophilus to prepare lactic acid bacteria oral liquid

[0028] In this embodiment, Lactobacillus acidophilus is selected for fermentation alone, and the pH value can be reduced to about 3.9 within 30 hours. Preparation method: mix 2 parts of brown sugar, 3 parts of glucose, 0.1 part of peptone, 0.02 part of magnesium sulfate, 0.02 part of manganese sulfate, 0.02 part of dipotassium hydrogen phosphate, and 0.1 part of sodium chloride, add purified tap water to dissolve, 116 Sterilize by passing steam at ℃; then add 1 portion of Lactobacillus acidophilus seed solution, culture at 37℃ for 30 hours, harvest when the pH drops to 3.9, and bottle. Acid production curve see image 3 . The obtained lactic acid bacteria oral liquid is a brown liquid with a sour taste and a live bacteria content of 1 billion / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com