Bile salt hydrolase and preparation method and special preparing strain thereof

A bile salt hydrolase and product technology, which is applied in the directions of hydrolase, microorganism-based methods, biochemical equipment and methods, etc., to achieve the effects of simple operation, reduced content, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, Lactobacillus casei (Lactobacillus casei) KTx separation and identification

[0030] 1. Screening of bacterial strains

[0031] 5ml of kefir filtrate was added to 45ml of normal saline (with glass beads) to make a bacterial suspension, and then 10-fold serial dilution of 10 6 ~10 8 times, take 1ml and pour it onto the plate (containing CaCO 3 MRS agar plate) was cultivated at 37°C for 24h, the colonies with dissolution circles were picked and placed in the MRS liquid tube for 12h enrichment at 37°C, stained with Grans, depending on the purity, the enrichment solution was drawn with 2% (volume ratio) The inoculum size was inoculated on No. I culture medium (containing 1 L of salt solution I and 1.0 g of cholesterol with cholesterol as the only carbon source; salt solution I (g / L): KH 2 PO 4 0.25; MgSO 4 ·7H 2 O 0.25; FeSO 4 5mg; NaCl 5mg; during preparation, dissolve cholesterol in saline solution I, then emulsify with ultrasonic cell pulverizer 500w...

Embodiment 2

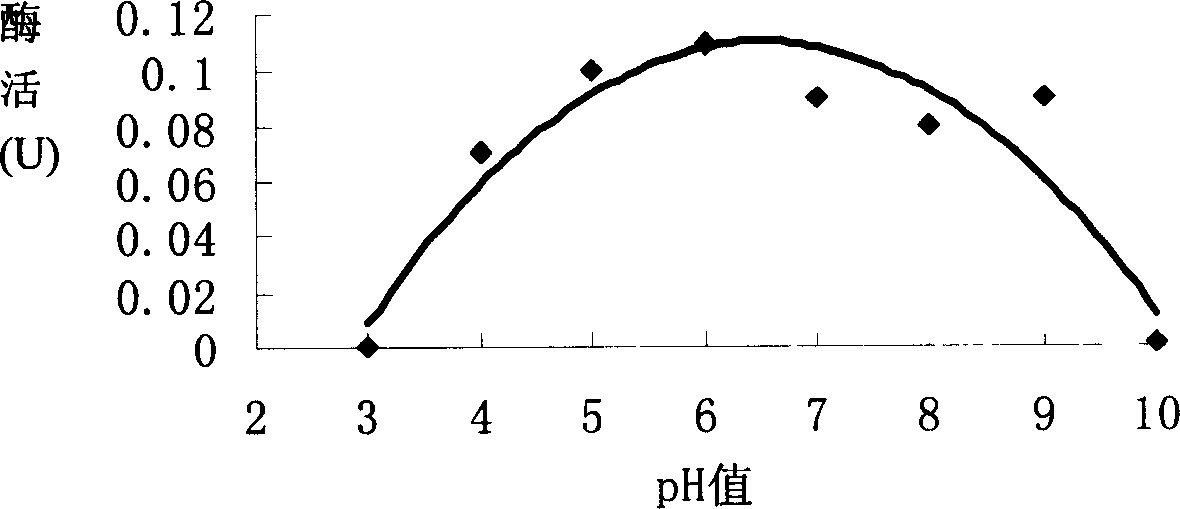

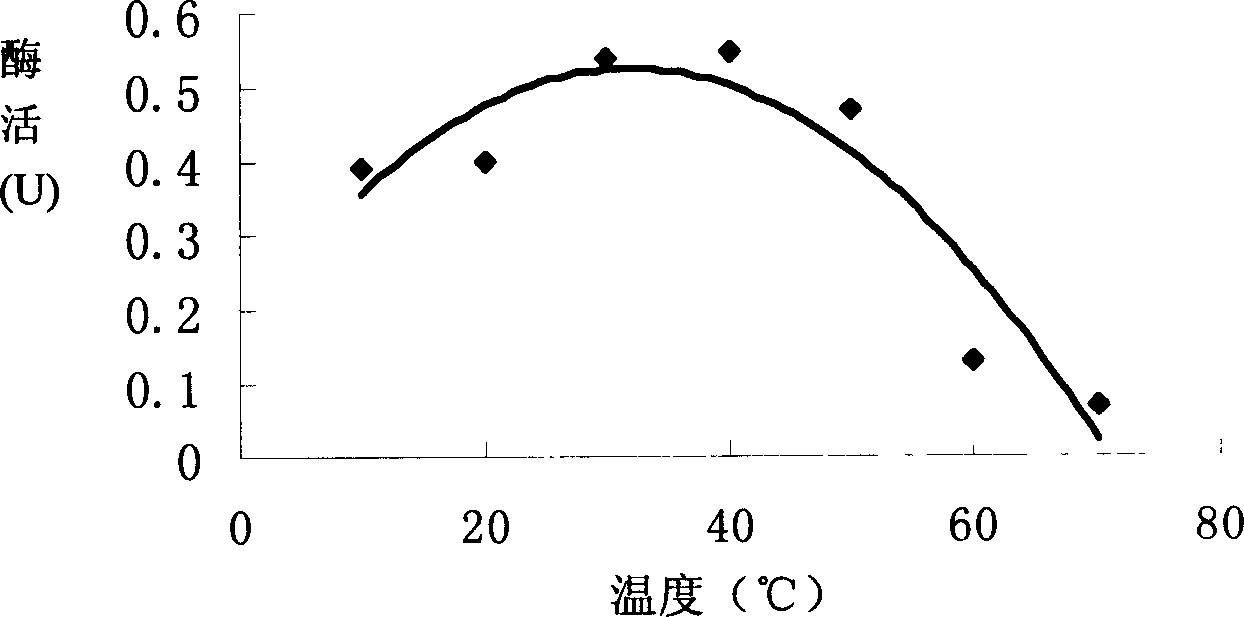

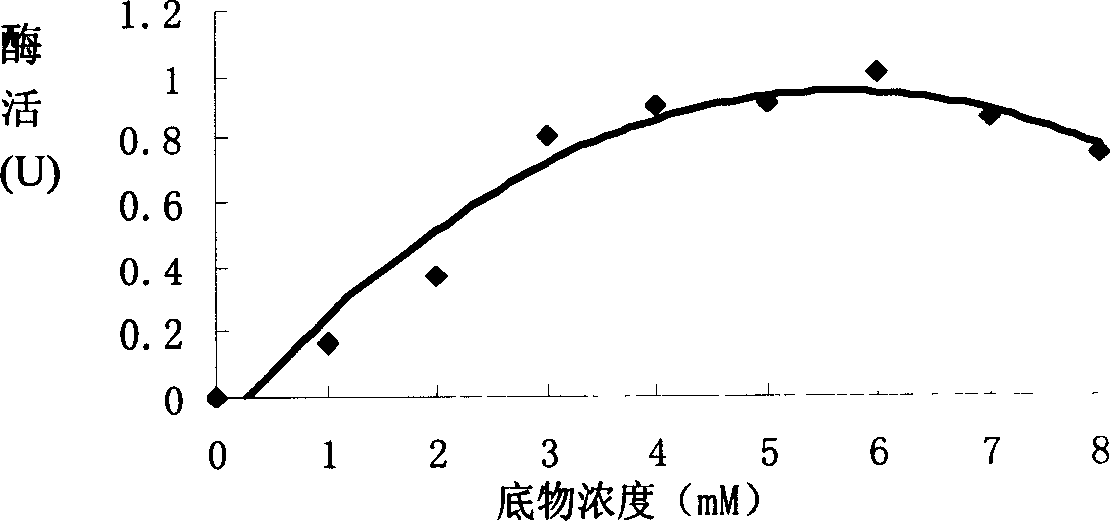

[0039] The optimization of the fermentation condition of embodiment 2, Lactobacillus casei (Lactobacillus casei) KTx and the detection of the bile salt hydrolyzing enzyme that fermentation obtains

[0040] One, the optimization of the fermentation condition of Lactobacillus casei (Lac tobacillus casei) KTx

[0041] 1, the selection of basal culture medium: Lactobacillus casei KTx CGMCC №.1739 adopts the inoculum size of 2% (V / V), inoculates respectively in MRS liquid culture medium, improves MRS liquid culture medium (MRS culture medium plus mass content is 3-4‰ corn steep liquor and cysteine hydrochloride with a mass content of 0.3-0.4‰), MRS broth medium (MRS-broth liquid medium) (tryptone 5g, beef extract 10g, yeast extract 5g , glucose 10g, triammonium citrate 1g, sodium acetate 2.5g, Tween 800.5mL, Na 2 HPO 4 1g, MnSO 4 0.025g, MgSO 4 ·7H 2 (20.05g, distilled water 500mL), after cultivating at 37 DEG C for 12h, measure its growth amount and produce the amount of bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com