Method and apparatus for treating exhaust gas

A waste gas treatment device and waste gas treatment technology, applied in the direction of separation methods, chemical instruments and methods, and methods for chemically changing substances by using atmospheric pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

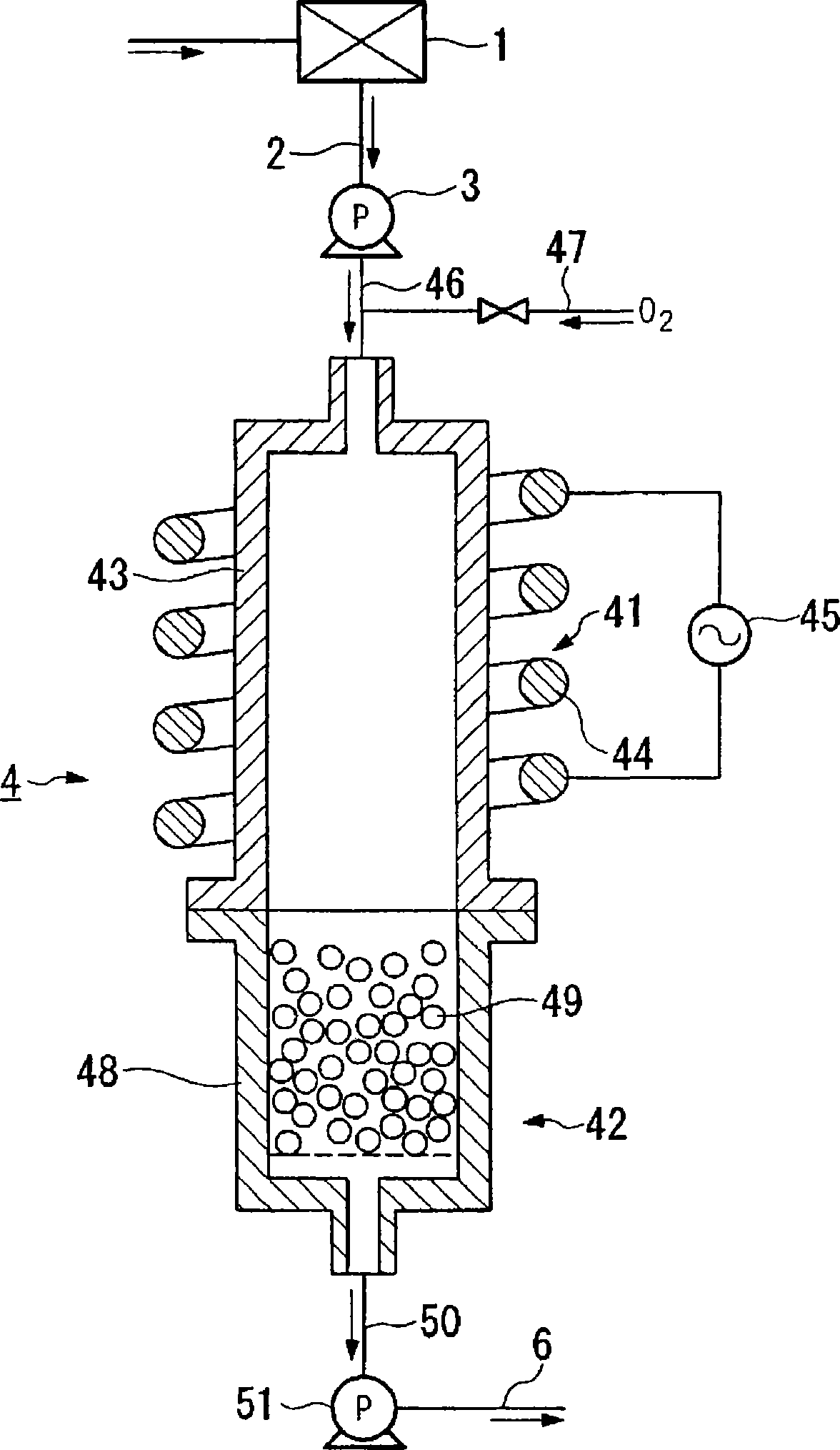

[0091] use figure 1 The shown treatment device treats exhaust gas discharged from a manufacturing facility 1 of semiconductor devices. As the processing tube 43 of the plasma processing unit 41, a cylindrical tube made of alumina with an inner diameter of 40 m is used, and a high-frequency coil 44 is wound thereon, and a frequency of 4 MHz and a maximum output power are applied to the high-frequency coil 44 from an AC power supply 45. The high-frequency current of 1.2 kW generates inductively coupled plasma in the processing tube 43 .

[0092] In addition, as the reactor 48 of the reaction removal part 42, a bottomed cylinder made of quartz with an inner diameter of 40 mm and a length of 150 mm was used, and 300 g of granular calcium oxide with a particle diameter of 1 mm was filled in the inside so that the porosity 50% by volume.

[0093] The pre-pump 3 and the post-pump 51 are operated, and exhaust gas in an excited state from the semiconductor device manufacturing equipm...

example 2

[0100] Using the same processing device as in Example 1, Ar: 20%, Xe: 78%, GeH 4 : 0.1%, B 2 h 6 : 0.1%, SiH 4 : A gas with a composition of 1.8% is introduced into the processing tube 43 under an excited state at a pressure of 50 Torr and a flow rate of 200 SCCM. At the same time, normal-pressure oxygen is introduced from the oxygen supply pipe 47 into the processing pipe 43 at a flow rate of 10 SCCM, and plasma is generated in the processing pipe 43 to oxidize and decompose harmful gas components in the exhaust gas. Thereafter, in the same reaction removal unit 42 as in Example 1, it is brought into contact with calcium oxide and removed.

[0101] For GeH in the exhaust gas discharged from the discharge pipe 50 4 , B 2 h 6 and SiH 4 As a result of quantification of the amount of GeH 4 : 3ppm (lower detection limit) or less, B 2 h 6 : 2ppm (lower detection limit) or less and SiH 4 : 3 ppm (lower detection limit) or less.

example 3

[0103] use figure 1 The treatment device shown is used to treat exhaust gases from a manufacturing facility 1 for semiconductor devices. As the processing tube 43 of the plasma processing part 41, use an inner diameter of 40mm aluminum oxide cylindrical tube, wind a high-frequency coil on it, and apply a frequency of 2MHz to the high-frequency coil from an AC power supply 45, and a maximum output power of The high-frequency current of 1.5 kW generates inductively coupled plasma in the processing tube 43 . In addition, as the reactor 48 of the reaction removal part 42, use an inner diameter of 40 mm and a length of 150 mm stainless steel with a bottom cylinder, and fill 20 kg of granular calcium oxide with a particle diameter of 3 mm in the interior so that the porosity is 50 mm. volume%.

[0104] The pre-pump 3 and the post-pump 51 are operated to introduce exhaust gas in an excited state from the semiconductor device manufacturing facility 1 through the introduction pipe 46...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com