Magnetic sandwich material based on nanocrystalline soft magnetic thin film and its preparing method

A nanocrystalline soft magnetic and sandwich technology, applied in the field of information storage, can solve problems affecting data security, hindering the development of spintronic devices, and reducing the magnetoresistance effect, achieving superior flip characteristics, superior soft magnetic properties, and reducing the overall The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

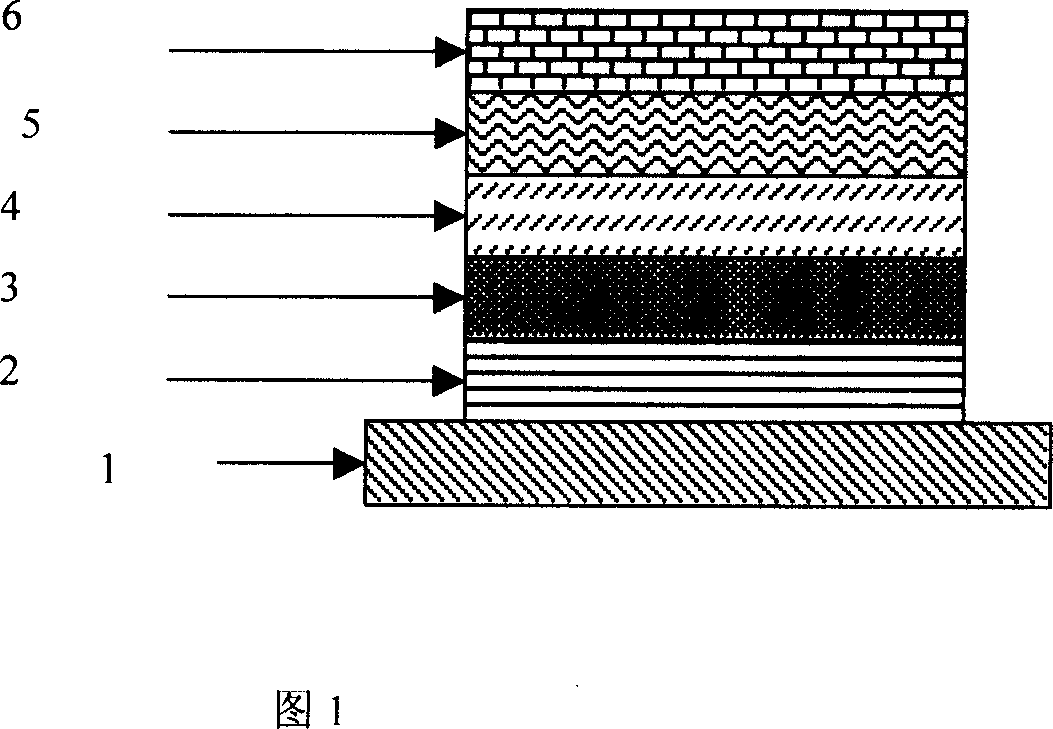

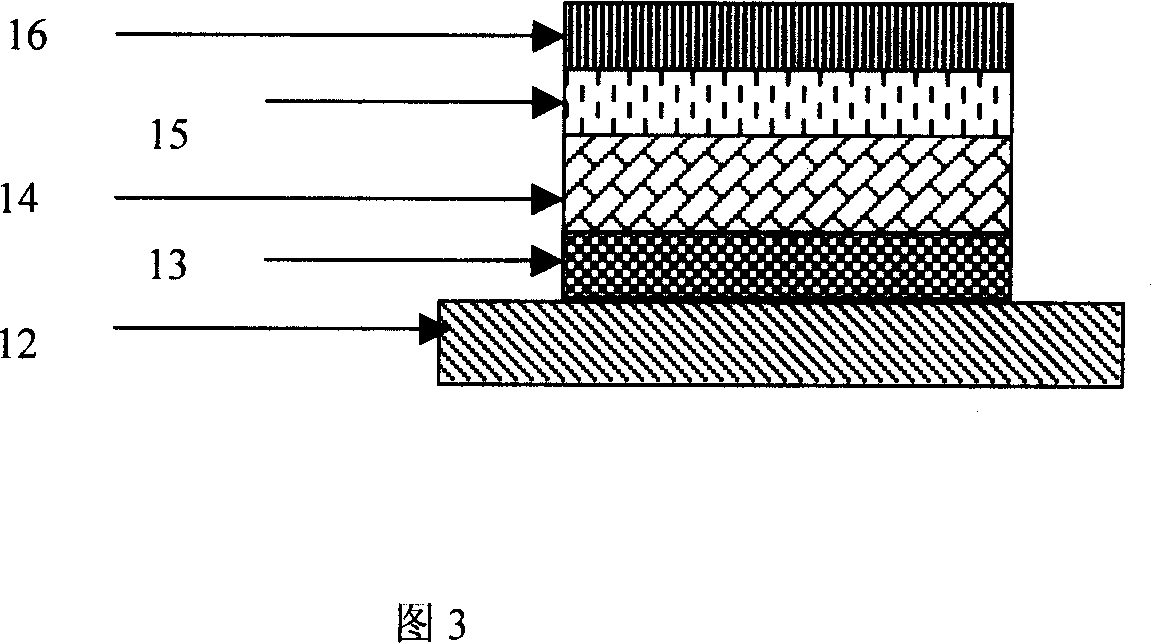

[0047] The following will take the nanocrystalline CoNbZr / Cu / Co structure as an example to illustrate the preparation method of the magnetic sandwich material proposed by the present invention.

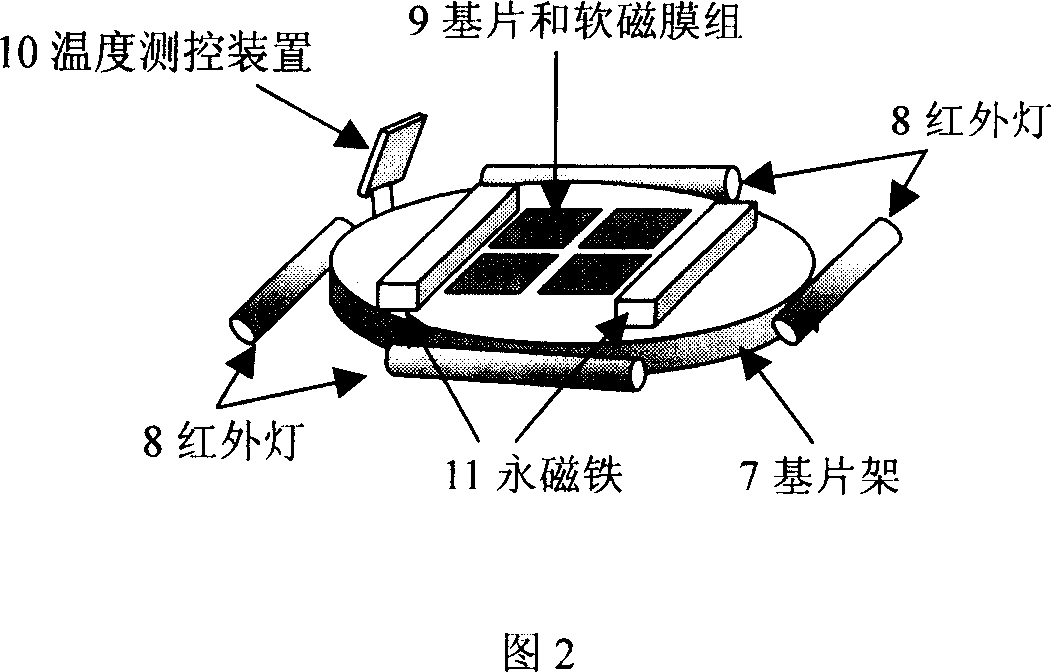

[0048] 1. Cleaning and handling of substrates

[0049] Prepare 10×10mm 2 Square single crystal Si(100) substrate, boiled with concentrated sulfuric acid to remove surface stains and impurities, ultrasonically cleaned with acetone, then soaked in hydrofluoric acid for 30 minutes to remove the surface oxide layer, ultrasonically cleaned with deionized water, and ultrasonically cleaned with acetone; then placed Dry on the filter paper, place on the substrate holder 7, and finally send it into the vacuum chamber of the sputtering station.

[0050] 2. Deposition and nanocrystallization of amorphous soft magnetic layer

[0051] Evacuate the sputtering table vacuum chamber to 1 × 10 -5 Pa, argon Ar is introduced as the working gas, and the partial pressure of argon is 0.2Pa. Add 50W sput...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com