Chitose graft alginate fibre, its production and use

A seaweed fiber, chitosan technology, applied in wet spinning, alginate man-made filaments and other directions, can solve the problems of wound infection, limit the wide application of seaweed fibers, etc., achieve high safety, good application prospects, The effect of rich source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

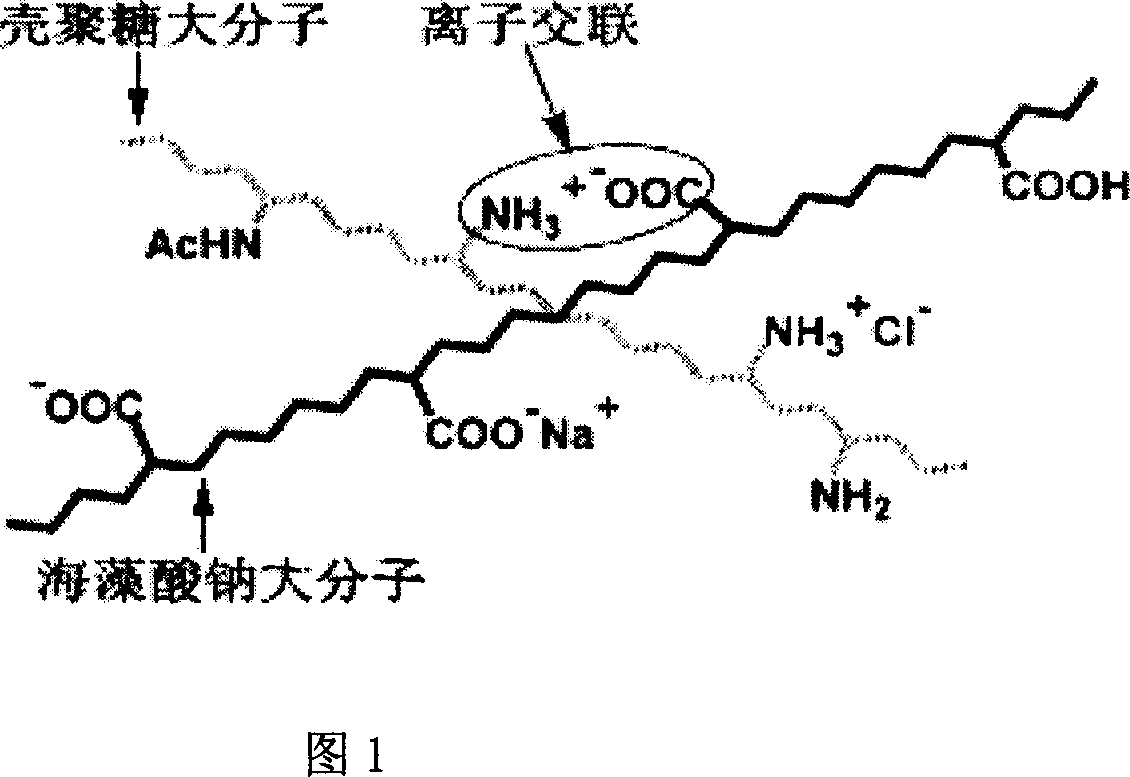

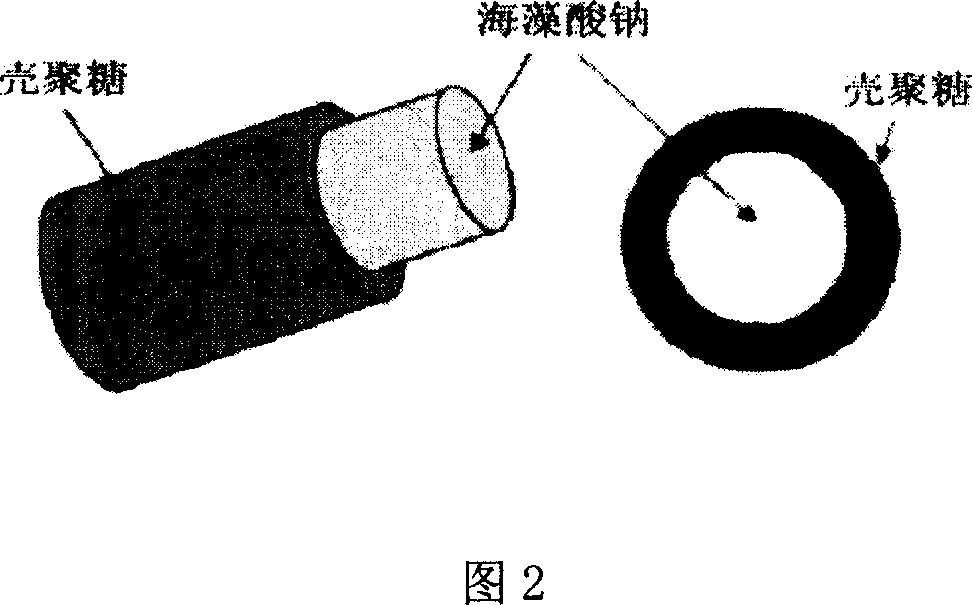

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: get 30g sodium alginate and be dissolved in 970mL distilled water and obtain the sodium alginate solution of 3% (mass percentage); Get an appropriate amount of chitosan, be dissolved in the acetic acid solution of 1% (mass percentage) to obtain 2% (mass percentage) percentage) chitosan solution; prepare 5% calcium chloride solution. After the sodium alginate solution is filtered and defoamed under reduced pressure, chitosan is prepared by wet spinning in a coagulation bath composed of a mixture of chitosan solution and calcium chloride solution with a volume ratio of 3:1 at room temperature. Sugar grafted seaweed fiber, the fiber stretch rate can reach 30%. And it can be further used as fiber raw material to make non-woven gauze for wound dressing.

Embodiment 2

[0025] Embodiment 2: get 40g sodium alginate and be dissolved in 960mL distilled water and obtain 4% (mass percentage) sodium alginate solution; Take appropriate amount of chitosan, dissolve in the acetic acid solution of 1.5% (mass percentage) to obtain 4% shell Polysaccharide solution; prepare 4% calcium chloride solution. After the sodium alginate solution is filtered and defoamed under reduced pressure, chitosan is prepared by wet spinning in a coagulation bath composed of a mixture of chitosan solution and calcium chloride solution with a volume ratio of 2:1 at room temperature. Sugar grafted seaweed fiber, the fiber stretch rate can reach 20%. And it can be further used as fiber raw material to make non-woven gauze for wound dressing.

Embodiment 3

[0026] Embodiment 3: get 50g sodium alginate and be dissolved in 950mL distilled water and obtain the sodium alginate solution of 5% (mass percentage); Get an appropriate amount of chitosan, be dissolved in the acetic acid solution of 2% (mass percentage) to obtain 6% (mass percentage) percentage) chitosan solution; prepare 2% (mass percentage) calcium chloride solution. After the sodium alginate solution is filtered and defoamed under reduced pressure, chitosan is prepared by wet spinning in a coagulation bath composed of a mixture of chitosan solution and calcium chloride solution with a volume ratio of 1:1 at room temperature. Sugar grafted seaweed fiber, the fiber stretch rate can reach 10%. And it can be further used as fiber raw material to make non-woven gauze for wound dressing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com