Method for modifying polyamide

A polyamide and modification technology, applied in the field of modified textile fibers, can solve the problems of no protease, no protease, no polyamide treatment, etc., to reduce energy consumption, improve environmental effectiveness, and improve properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Example 1. Increase of carboxyl end groups of polyamide 6.6 monofilaments treated with protease

[0075] Two types of polyamide 66 monofilament yarns (pA yarn, type F111, diameter 0.035 mm and type D183, diameter 0.5 mm, Rhodia Industrial Yarns AG, Emmenbriicke, Switzerland) were treated with protease. Prior to enzyme treatment, PA yarn was extracted with diethyl ether to remove spin finishes. Extraction was performed in a Soxhlet-Extractor and about 150 ml diethyl ether was used to extract about 10 g polyamide. The extraction time is 2 hours. After extraction the silk is air dried.

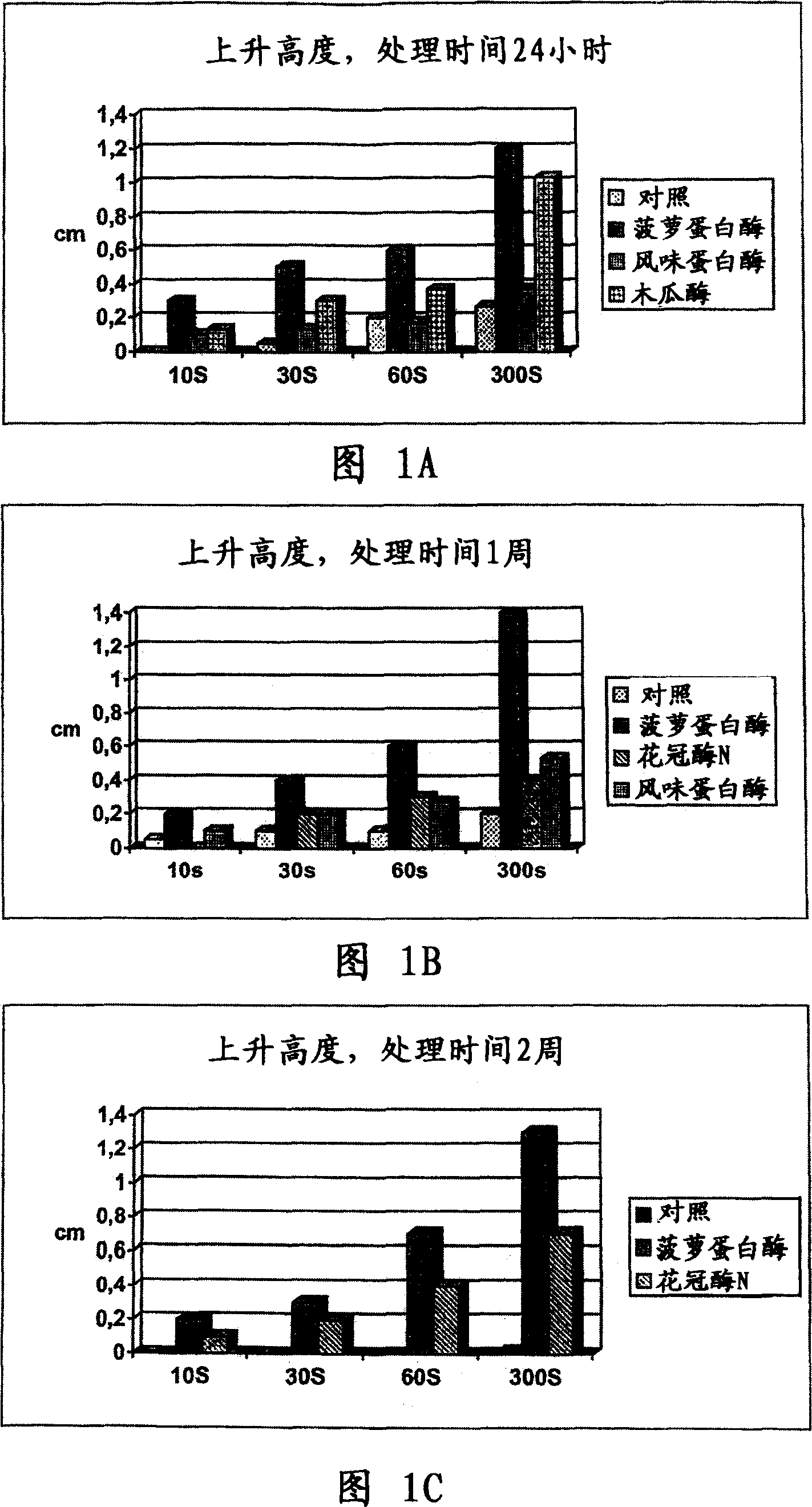

[0076] 2 g of PA yarn was treated in 0.1 M sodium phosphate buffer 7 or 0.1 M sodium citrate pH 4.5 at a liquid ratio of 1:15 with 20 and 1000 nkat protease / g yarn at 50°C for 2 and 24 hours. Protease activity (nkat) was measured as indicated in Example 2. Four different commercial proteases were used: Protex Multiplus L (Genencor Intl, serine protease, pH 7), corolla enzyme N (AB Enzy...

Embodiment 2

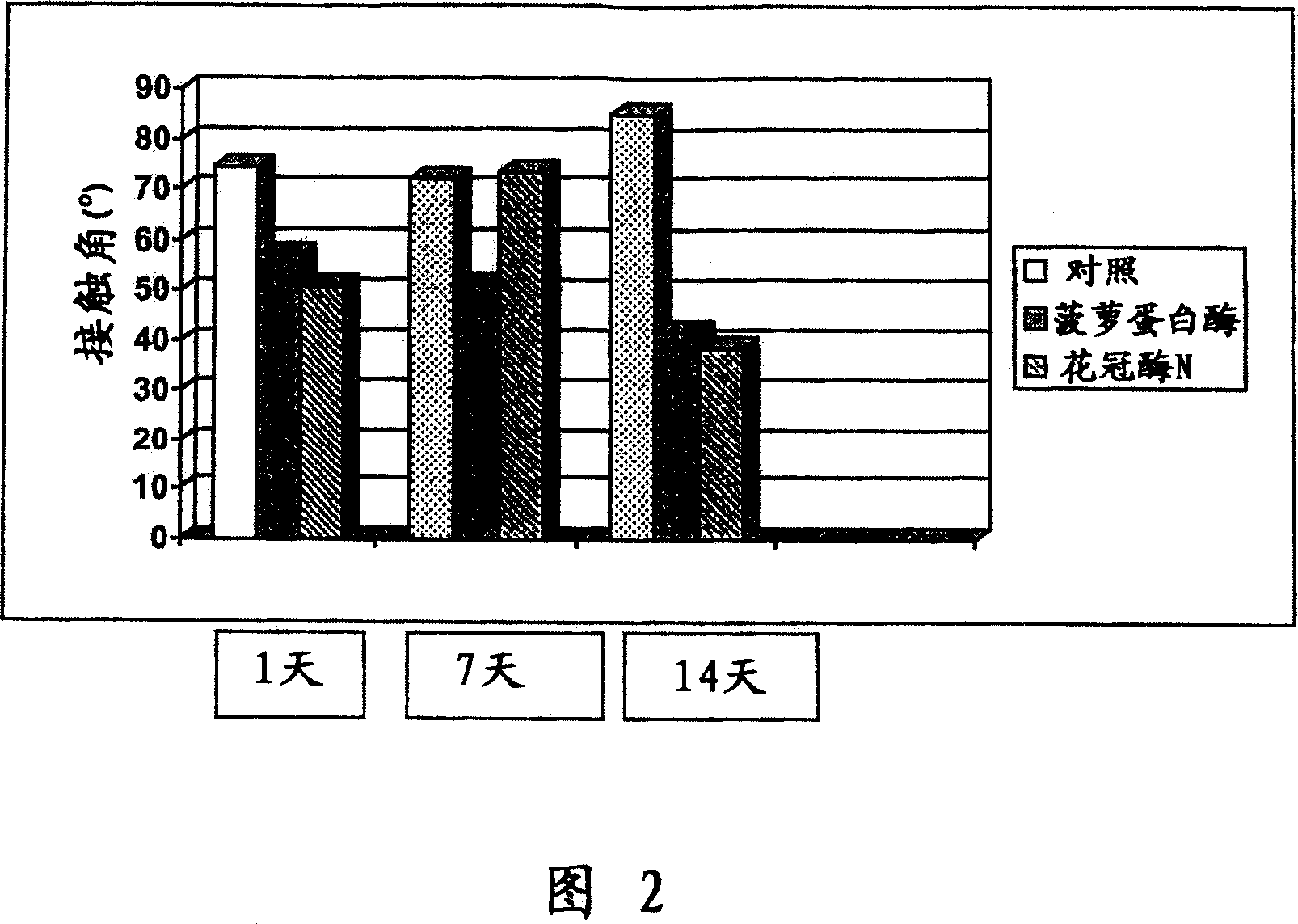

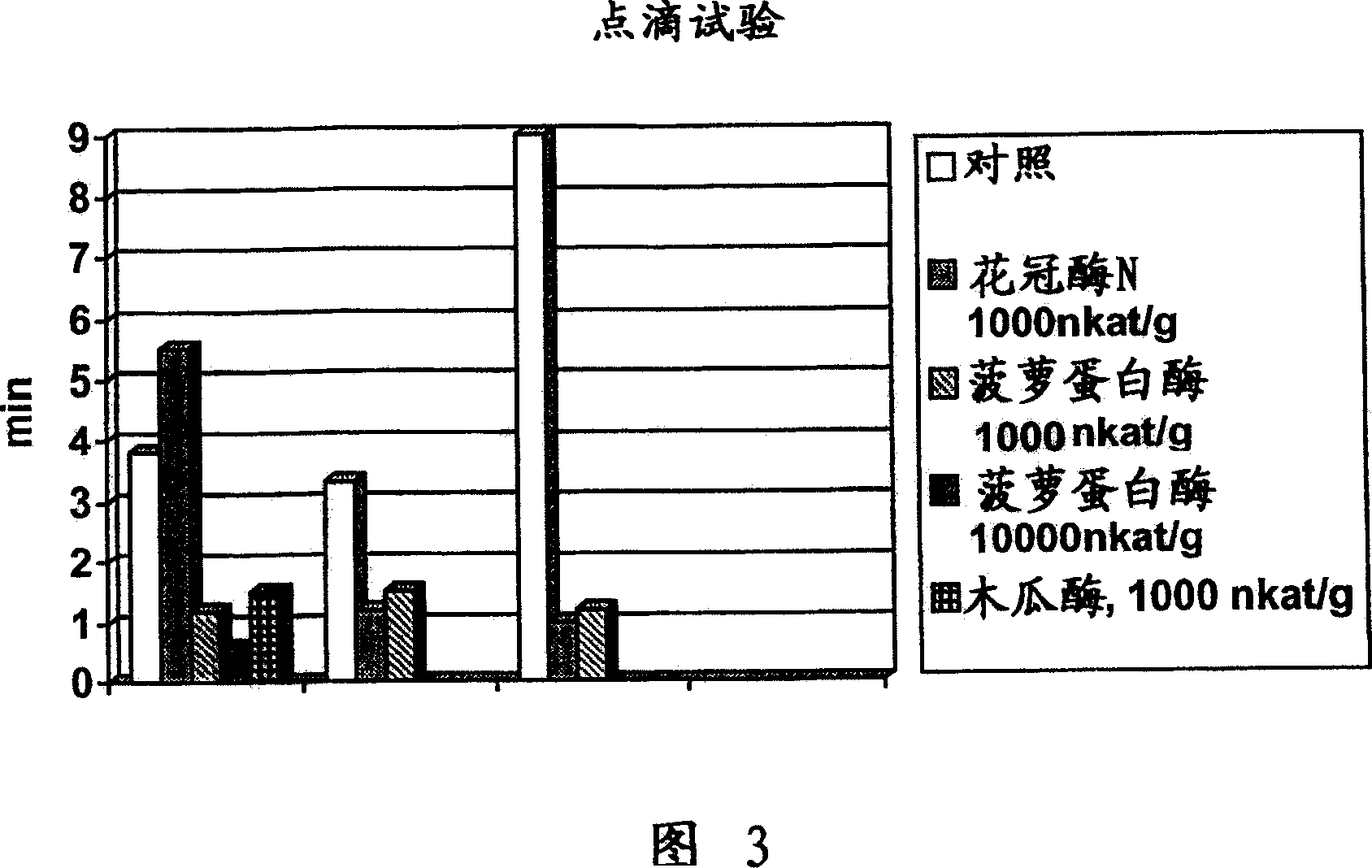

[0106] Embodiment 2. Improve the hydrophilicity of polyamide fabric with protease

[0107] Polyamide 66 fabric (63g / m 2, Rhodia Industrial Yarns AG, Emmenbrucke, Switzerland) to remove the spin finish by washing with OMO detergent (Lever Faberge) in a domestic washing machine Hoover with washing program no. 7 at 40°C. 2g PA fabric in 1:20 liquid ratio with 1000nkat and 10000nkat / g fabric bromelain, 1000nkat / g papain and corolla enzyme N or with 1mg protein / g fabric flavor protease in 0.1M sodium phosphate buffer 7 or citric acid Treatment was at 50°C for 1, 7 and 14 days in sodium buffer pH 5. Protease activity (nkat) was measured according to the endoprotease assay using Protazyme AK tablets (Megazyme International Ireland Ltd., Ireland). Protein concentration was measured according to the method of Lowry et al. (Lowry, O.H., N.J. Rosebrough, A.L. Farr, and R.J. Randall. 1951. Protein measurement with the Folin phenol reagent. J. Biol. Chem. 193:265). Different commercial ...

Embodiment 3

[0110] Example 3. Improvement of dyeing properties of polyamide fabrics treated with proteases: methylene blue dyeing

[0111] Polyamide 66 fabrics were treated with 1000 and 10000 nkat / g bromelain Conc. (Genencor Intl), 1000 nkat / g corolla enzyme N (AB Enzymes GmbH) and with 1 mg / g flavor protease (Novozymes) as described in Example 2 . Enzyme-treated fabrics are dyed with the cationic dye methylene blue.

[0112] Methylene blue staining was carried out at 85° C. for 5 minutes with 0.1% methylene blue (methylene blue B, Merck) at a liquid ratio of 1:100. Wash the fabric with water to remove excess dye. The dyed fabric was dried overnight on filter paper. The color of the fabrics was measured with a Minolta Chroma Meter using the L*a*b* system.

[0113] After dyeing with methylene blue, the L-value (lightness) of fabrics treated with bromelain (1000 and 10000 nkat / g) and corolla enzyme N (1000 nkat / g) was clearly reduced, showing better dyeing than the control (Fig. 4A an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com