Preparation process of monodispersive silica sol

A technology of silica and monodispersity, applied in the direction of silica, silica, etc., can solve the problem of difficult preparation of monodisperse silica sol particles, difficulty in precisely controlling the addition speed of silica powder, and difficulty in preparing small particle size silica Sol and other problems, to achieve the effect of low cost, good product quality and good operation controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Take 2000 grams of distilled water and add it to a reactor equipped with a reflux condenser, add 250 grams of 200-mesh commercial silicon powder and 5 grams of sodium hydroxide, start the stirrer and heat up to 75 ° C;

[0035] (2) take by weighing 10 grams of sodium hydroxide and join in 1000 grams of distilled water;

[0036] (3) Slowly add the lye obtained in the above step (2) into the mixed solution obtained in the step (1), and control the initial addition rate to be 250 grams of solution per hour. Then gradually increase the speed of adding lye, and finish adding in about 3 hours. Then continue to react for 2-3 hours. When the solution is cooled to 50°C, filter or centrifuge to obtain nano-silica sol.

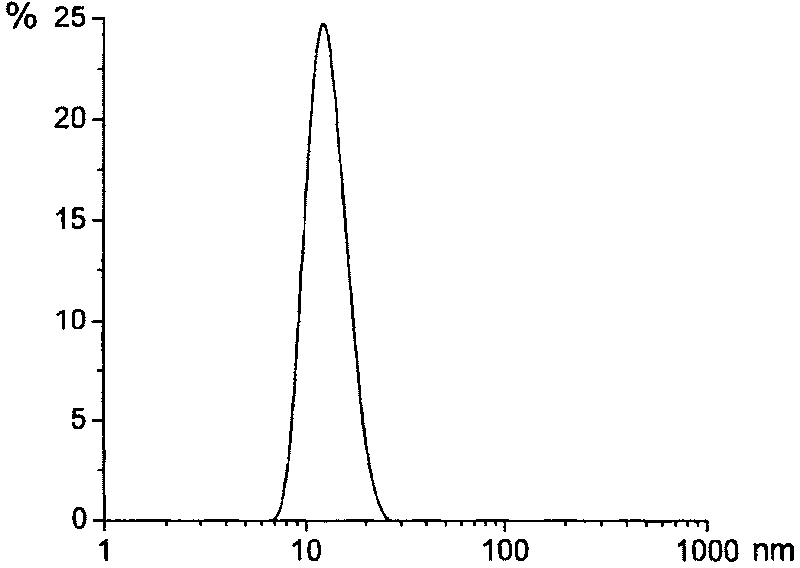

[0037] The particle diameter measured by a dynamic light scattering laser particle size and potential analyzer is 18 nanometers, see figure 1 , where the abscissa is the particle size, and the ordinate is the percentage of different particles. SiO 2 The c...

Embodiment 2

[0039] (1) Get 300 grams of the silica sol solution gained in Example 1 and add it to 1700 grams of distilled water. Start the stirrer and heat to 80°C;

[0040] (2) Add 100 grams of commercially available 300 mesh silicon powder and stir;

[0041] (3) Take by weighing 15 grams of sodium hydroxide and join in 1000 grams of distilled water, then add 10 grams of ammonia water, mix well;

[0042] (4) Slowly add the lye obtained in step (3) into the mixed solution obtained in step (2), finish adding in about 4 hours, and continue to react for 1 hour;

[0043] (5) continue to add 225 grams of silicon powder in step (4) gained mixed solution, stir;

[0044] (6) Weigh 20 grams of NaOH, add it to 1500 grams of distilled water, and mix evenly; slowly add the lye to the mixed solution obtained in step (5), and add it in about 8 hours. Continue to react for 2 to 3 hours. When the solution is cooled to 50°C, it is filtered or centrifuged to obtain nano-silica sol.

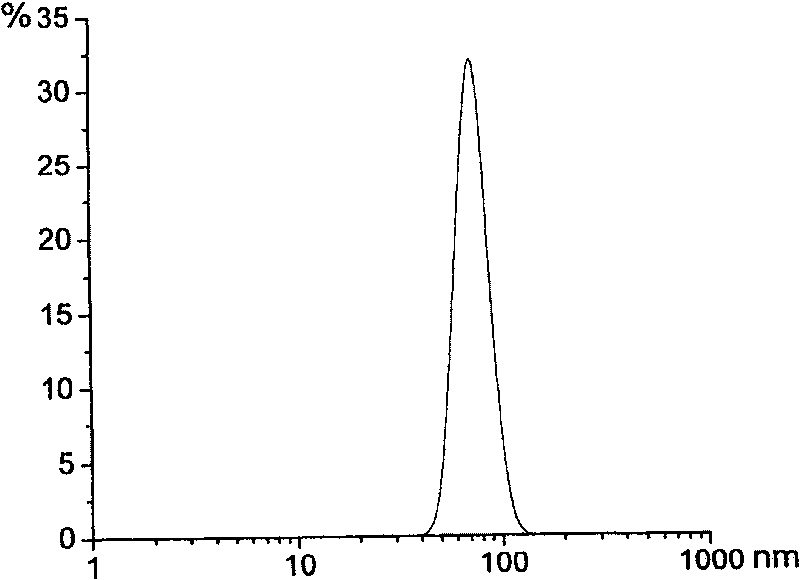

[0045] The partic...

Embodiment 3

[0047] (1) Take 2000 grams of distilled water and add it to a reactor equipped with a reflux condenser, add 150 grams of 200-mesh commercially available silicon powder and 5 grams of sodium hydroxide, start the stirrer and heat up to 75 ° C;

[0048] (2) Take by weighing 10 grams of sodium hydroxide and join in 1000 grams of distilled water, then add 10 grams of ammonia water, mix well;

[0049] (3) Slowly add the lye obtained in the above step (2) into the mixed solution obtained in the step (1), and control the initial addition rate to be 150 grams of solution per hour. Then gradually increase the speed of adding lye, and finish adding in about 6 hours. Then continue to react for 1 hour;

[0050] (4) Add 500 grams of silicon powder in the above solution, and continue to stir;

[0051] (5) Take by weighing 45 grams of NaOH, join in 2500 grams of water, mix well;

[0052] (6) Add lye as shown in step (3), and add it in about 8 hours. Continue to react for 2 to 3 hours. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com