Fast protease microreactor and its production

A technology of proteolytic enzyme and reactor, which is applied in the field of miniature fast proteolytic enzyme reactor and its preparation, can solve the problems of high price and limited application of active monomers, and achieve good permeability and bioaffinity, and application The effect of high potential and increased reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

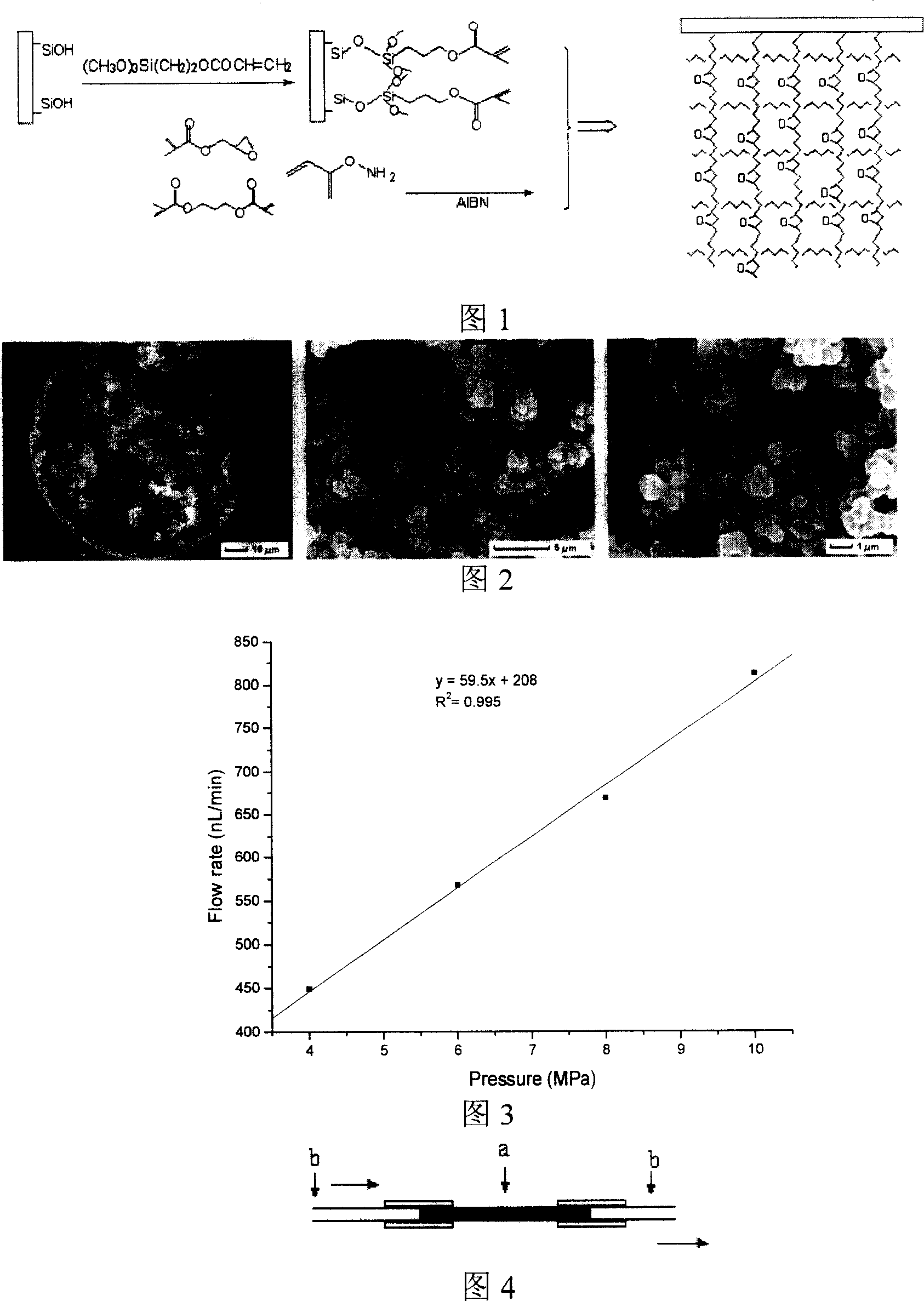

Embodiment 1

[0035]1) Preparation of monolithic matrix: as shown in Figure 1, select glycidyl methacrylate (GMA), acrylamide and ethylidene dimethacrylic acid (EDMA) as monomers to synthesize monolithic matrix in capillary. The inner wall of the capillary is pre-modified by a silane reagent (3-trimethoxysilyloxypropyl methacrylate, γ-MAPS) with a double bond functional group, and monomers are polymerized in it and fixed on the capillary wall by chemical bonds. Specifically, such a porous material is polymerized in-situ in a capillary to form an integral matrix enzyme reactor and applied to hydrolysis experiments of various substrates. Weigh 90mg of GMA, 60mg of acrylamide and 150mg of EDMA, dissolve in 700mg of cyclohexanol / dodecanol (mass ratio 85 / 15) mixed solvent, heat to above 50°C, oscillate and mix, cool to room temperature, add content AIBN accounting for 1% of the total mass ratio of the monomer was used as an initiator, and after 10 minutes of nitrogen gas flow, ultrasonic degassi...

Embodiment 2

[0040] 1) Preparation of monolithic matrix: as shown in Figure 1, select glycidyl methacrylate (GMA), acrylamide and ethylidene dimethacrylic acid (EDMA) as monomers to synthesize monolithic matrix in capillary. The inner wall of the capillary is pre-modified by a silane reagent (3-trimethoxysilyloxypropyl methacrylate, γ-MAPS) with a double bond functional group, and monomers are polymerized in it and fixed on the capillary wall by chemical bonds. Specifically, such a porous material is polymerized in-situ in a capillary to form an integral matrix enzyme reactor and applied to hydrolysis experiments of various substrates. Weigh 90mg of GMA, 60mg of acrylamide and 150mg of EDMA, dissolve in a mixed solvent of 700mg of cyclohexanol / dodecanol (mass ratio 50 / 50), heat to 80°C, shake and mix well, after cooling to room temperature, add the content of AIBN with a total monomer mass ratio of 2% was used as an initiator, and after nitrogen gas flow for 10 minutes, ultrasonic degassin...

Embodiment 3

[0045] 1) Preparation of monolithic matrix: as shown in Figure 1, select glycidyl methacrylate (GMA), acrylamide and ethylidene dimethacrylic acid (EDMA) as monomers to synthesize monolithic matrix in capillary. The inner wall of the capillary is pre-modified by a silane reagent (3-trimethoxysilyloxypropyl methacrylate, γ-MAPS) with a double bond functional group, and monomers are polymerized in it and fixed on the capillary wall by chemical bonds. Specifically, such a porous material is polymerized in-situ in a capillary to form an integral matrix enzyme reactor and applied to hydrolysis experiments of various substrates. Weigh 90mg of GMA, 60mg of acrylamide and 150mg of EDMA, dissolve in a mixed solvent of 700mg of n-propanol / 1,4-butanediol (mass ratio 60 / 40), heat to above 50°C, shake and mix well, and cool to room temperature , adding AIBN with a content of 1% of the total mass ratio of monomers as an initiator, and after passing nitrogen gas for 10 minutes, ultrasonic de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com