Oral disintegrated rupatadine tablet and its preparing method

A technology of orally disintegrating tablets and preparations, applied in the field of rupatad orally disintegrating tablets, can solve problems such as poor compliance and restrictive effects, and achieve the effects of easy promotion and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

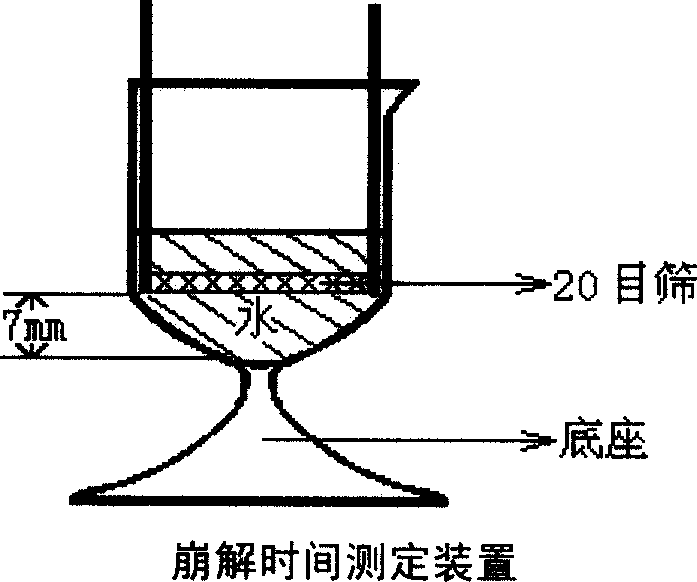

Image

Examples

Embodiment 1

[0025] Rupatadine Fumarate 5%

[0026] Dextrin 18%

[0027] Mannitol 35%

[0028] Lactose 30%

[0029] Low-substituted hydroxypropyl cellulose (L-HPC) 8%

[0030] Aspartame 2%

[0031] Talc 1.5%

[0032] Magnesium Stearate 0.5%

[0033] The dosage form can be produced by conventional tablet pharmaceutical equipment and prepared by a compression process. The specific preparation method is as follows: aspartame and rupatadine are respectively pulverized through an 80-mesh sieve, weighed according to the prescription amount, mixed evenly, and Pass dextrin, mannitol, lactose, low-substituted hydroxypropyl cellulose, talcum powder, and magnesium stearate through an 80-mesh sieve respectively, weigh them according to the prescription amount, mix them evenly, and then mix them with Lupa mixed with aspartame He decided to mix, sieve and mix evenly, measure the content of the semi-finished product, calculate the tablet weight, compress the tablet, test the hardness of the tablet,...

Embodiment 2

[0036] Rupatadine Fumarate 6%

[0037] Lactose 35%

[0038] Mannitol 40%

[0039] Low-substituted hydroxypropyl cellulose (L-HPC) 8%

[0040] Croscarmellose Sodium (CCNa) 2.5%

[0041] Aspartame 2.5%

[0042] Strawberry flavor 2.0%

[0043] Sweet Orange Flavor 2.0%

[0044] Talc 1.5%

[0045] Magnesium Stearate 0.5%

[0046] The dosage form can be produced by using conventional tablet pharmaceutical equipment and prepared by pressing process. The specific preparation method is as follows: aspartame, strawberry essence, sweet orange essence, and rupatadine are respectively crushed through an 80-mesh sieve. Weigh and mix evenly, and separately pass lactose, mannitol, low-substituted hydroxypropyl cellulose, croscarmellose sodium, and magnesium stearate through an 80-mesh sieve, weigh them according to the prescription amount, mix evenly, and then Mix with rupatadine mixed with aspartame, etc., sieve and mix evenly, measure the content of the semi-finished product, calcul...

Embodiment 3

[0049] Rupatadine Fumarate 8%

[0050] Lactose 40%

[0051] Mannitol 38%

[0052] Sodium Carboxymethyl Starch (CMS-Na) 3%

[0053] Stevioside 3%

[0054] Peppermint Flavor 1.5%

[0055] Strawberry flavor 2.0%

[0056] Sweet Orange Flavor 2.0%

[0057] Talc 1.5%

[0058] Magnesium Stearate 1.0%

[0059]The dosage form can be produced by conventional tablet pharmaceutical equipment and prepared by pressing technology. The specific preparation method is as follows: respectively crush stevioside, strawberry essence, sweet orange essence, mint essence, and rupatadine through an 80-mesh sieve, and press the prescription Weigh and mix evenly, and separately pass lactose, mannitol, sodium carboxymethyl starch, and magnesium stearate through 80 mesh sieves, weigh them according to the prescription amount, mix evenly, and then mix with Lupa mixed with stevioside, etc. He decided to mix, sieve and mix evenly, measure the content of the semi-finished product, calculate the tablet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com