Positive resist composition suitable for lift-off technique and pattern forming method

a technology of resist and lift-off technique, applied in the direction of photosensitive materials, instruments, photomechanical equipment, etc., can solve the problems of low processing precision, low reliability, and often complex steps of lift-off technique, and achieve the effect of improving the accuracy of the effect of forming and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis examples 1-5

Synthesis of Alkali-Soluble Resins

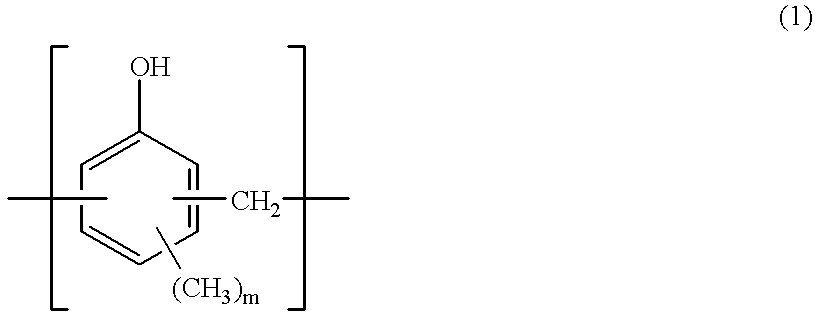

[0081] A three-necked flask equipped with a stirrer, condenser and thermometer was charged with 64.8 g (0.6 mol) of p-cresol, 162.3 g (1.50 mol) of m-cresol, 110.1 g (0.90 mol) of 3,5-xylenol, 133.8 g (1.65 mol) of an aqueous solution of 37 wt % formaldehyde, and 0.90 g (7.2.times.10.sup.-3 mol) of oxalic acid dihydrate as a polycondensation catalyst. The flask was immersed in an oil bath to maintain an internal temperature of 100.degree. C. and polycondensation reaction took place for one hour.

[0082] At the end of reaction, 1,500 ml of methyl isobutyl ketone (MIBK) was added to the reaction solution which was stirred for 30 minutes. The aqueous layer was separated off. The MIBK layer in which the product was extracted was washed 5 times with 900 ml of pure water, followed by separation and vacuum stripping by means of an evaporator at 4 mmHg and 150.degree. C. As a result, 245 g of a novolak resin A-1 was prepared.

[0083] Like novolak resin A-1, nov...

synthesis examples 6-15

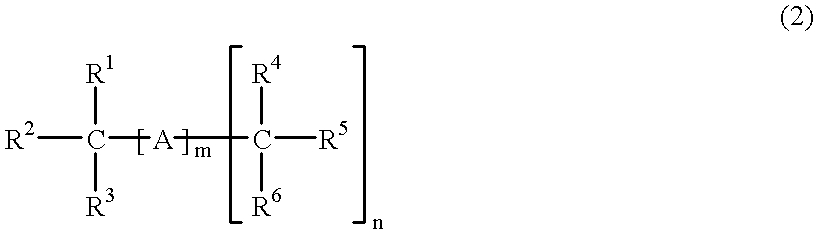

Synthesis of 1,2-Naphthoquinonediazidosulfonyl-Introduced Novolak Resins

[0084] Under a light-shielded condition, a three-necked flask equipped with a stirrer, dropping funnel and thermometer was charged with 150 g (1.2 mol) of novolak resin A-1 (OH equivalent 124.4), 19.3 g (0.072 mol) of 1,2-naphthoquinone-2-diazido-5-sulfonyl chloride, and 760 g of 1,4-dioxane. At room temperature, 8.0 g (0.079 mol) of triethylamine was added dropwise to the solution. After the dropwise addition, stirring was continued for 10 hours. The reaction solution was poured into a large volume of a 0.12N hydrochloric acid solution whereupon the resin precipitated. The resin was prepared, dissolved in 600 g of ethyl acetate, and washed three times with 200 g of water. Separation and vacuum stripping at 40.degree. C. yielded 140 g of 1,2-naphthoquinone-2-diazido-5-sulfonyl-introduced novolak resin B-1.

[0085] As shown in Table 2, novolak resins B-2 through B-10 having a 1,2-naphthoquinone-2-diazido-4-sulfonyl...

synthesis example 16

Synthesis of 1,2-Quinonediazide Compound

[0086] Under a light-shielded condition, a three-necked flask equipped with a stirrer, dropping funnel and thermometer was charged with 10.0 g (43.4 mmol) of 2,3,4-trihydroxybenzophenone, 35.0 g (130 mmol) of 1,2-naphthoquinone-2-diazido-5-sulfonyl chloride, and 200 g of 1,4-dioxane. The flask was immersed in a water bath to control its temperature below 25.degree. C. To the flask, a solution of 10.50 g of 1,4-diazabicyclo[2.2.2]octane (DABCO) in 100 g of 1,4-dioxane as a catalyst was added dropwise through the dropping funnel. The precipitated DABCO hydrochloride salt was removed by filtration and with stirring, the filtrate was added dropwise to 1,800 g of 0.12N hydrochloric acid for re-precipitation. The solution was subject to filtration again. The precipitate was extracted with 300 ml of ethyl acetate, washed 5 times with 100 g of pure water and separated. Vacuum stripping by means of an evaporator below 40.degree. C. yielded 41.0 g of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| mol % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com