Silver alloy material, circuit substrate, electronic device, and method for manufacturing circuit substrate

a technology of silver alloy and circuit substrate, which is applied in the direction of non-linear optics, identification means, instruments, etc., can solve the problems of large equipment cost, limited usable range of silver, and significant lack of heat resistance of silver, so as to achieve high plasma resistance, high heat resistance, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0098] [First Embodiment]

[0099] The following will explain an embodiment of the present invention.

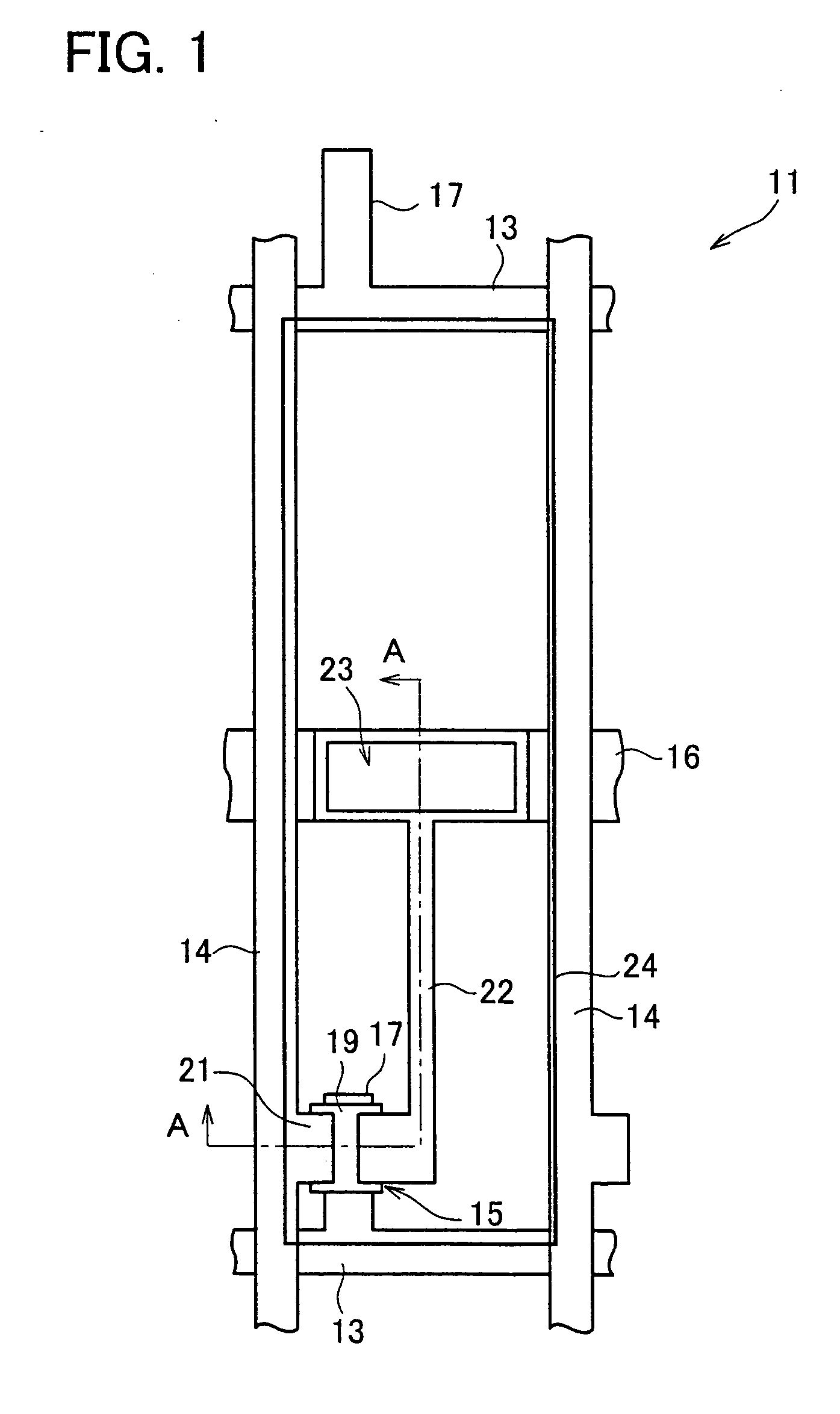

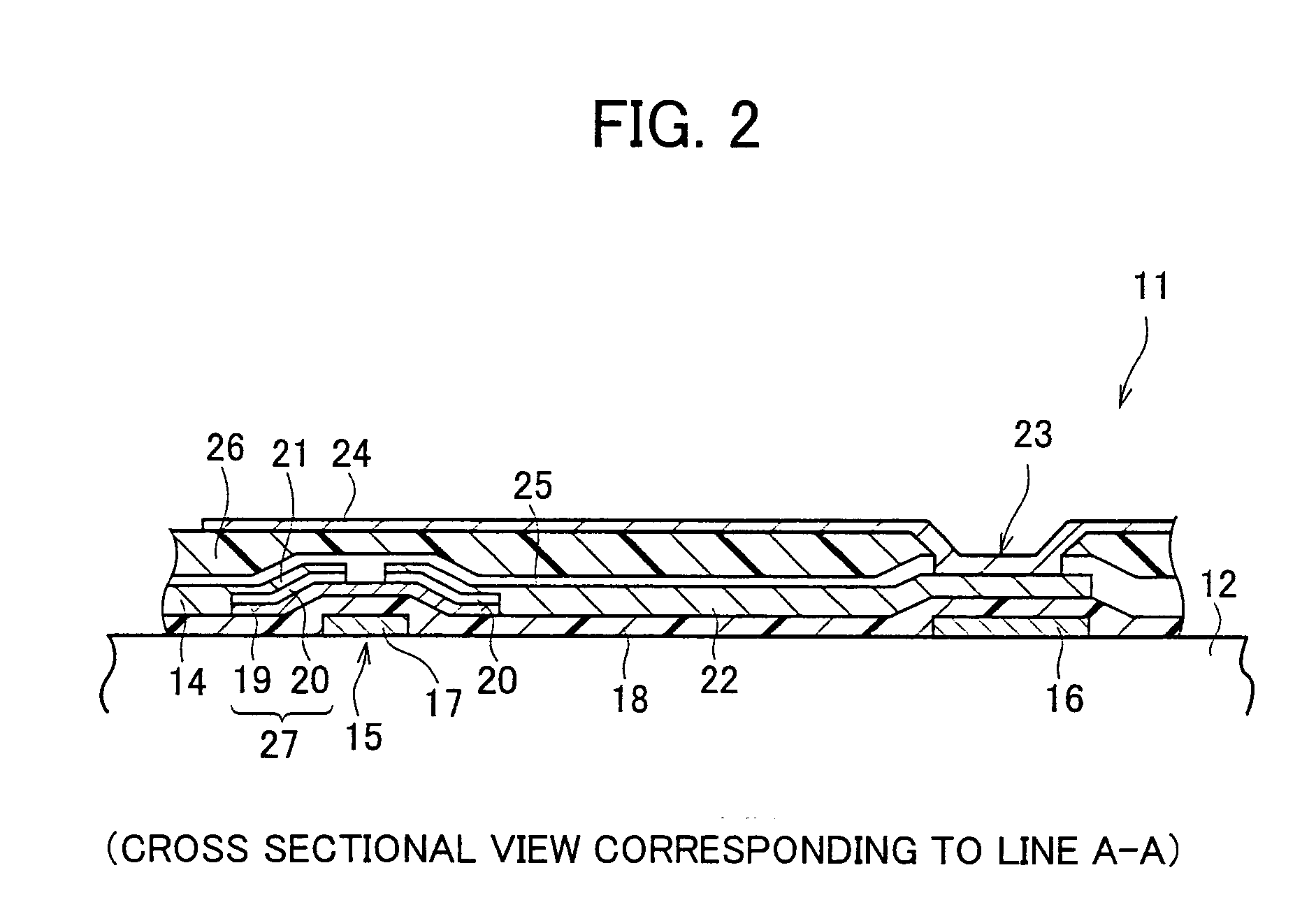

[0100] In the present embodiment, a silver alloy material of the present invention will be explained first, and then a TFT array substrate and liquid crystal display device using the silver alloy material will be explained.

[0101] A silver alloy material of the present invention which composes lines and / or electrodes formed on an insulation substrate such as a glass substrate is arranged so as to contain silver as a main component and at least one element selected from the group consisting of tin, zinc, lead, bismuth, indium, and gallium.

[0102] With the silver alloy material as arranged above, it is possible to form lines and / or electrodes having low electric resistance, as well as high process resistance such as heat resistance, adhesion to the glass substrate, and plasma resistance.

[0103] With reference to Examples 1 through 9 and Comparative Examples 1 and 2, the following will de...

second embodiment

[0266] [Second Embodiment]

[0267] The following will explain another embodiment of the present invention with reference to FIGS. 6, 19(a), and 19(b).

[0268] In First Embodiment, the pattern formation equipment employing an ink-jet method, for example, is used in the gate line formation step 102 and the source and drain lines formation step 106.

[0269] A TFT array substrate 71 in accordance with the present embodiment is produced in a manner as shown in the process flow chart of FIG. 6 as in First Embodiment, except that in the gate line formation step 102, two or more types of fluid wiring materials are used to form the lines and the like having different compositions within the substrate (separate application).

[0270] Note that, constituent elements substantially having the same function as those used in First Embodiment are given the same reference symbols, thus their explanation will be omitted here.

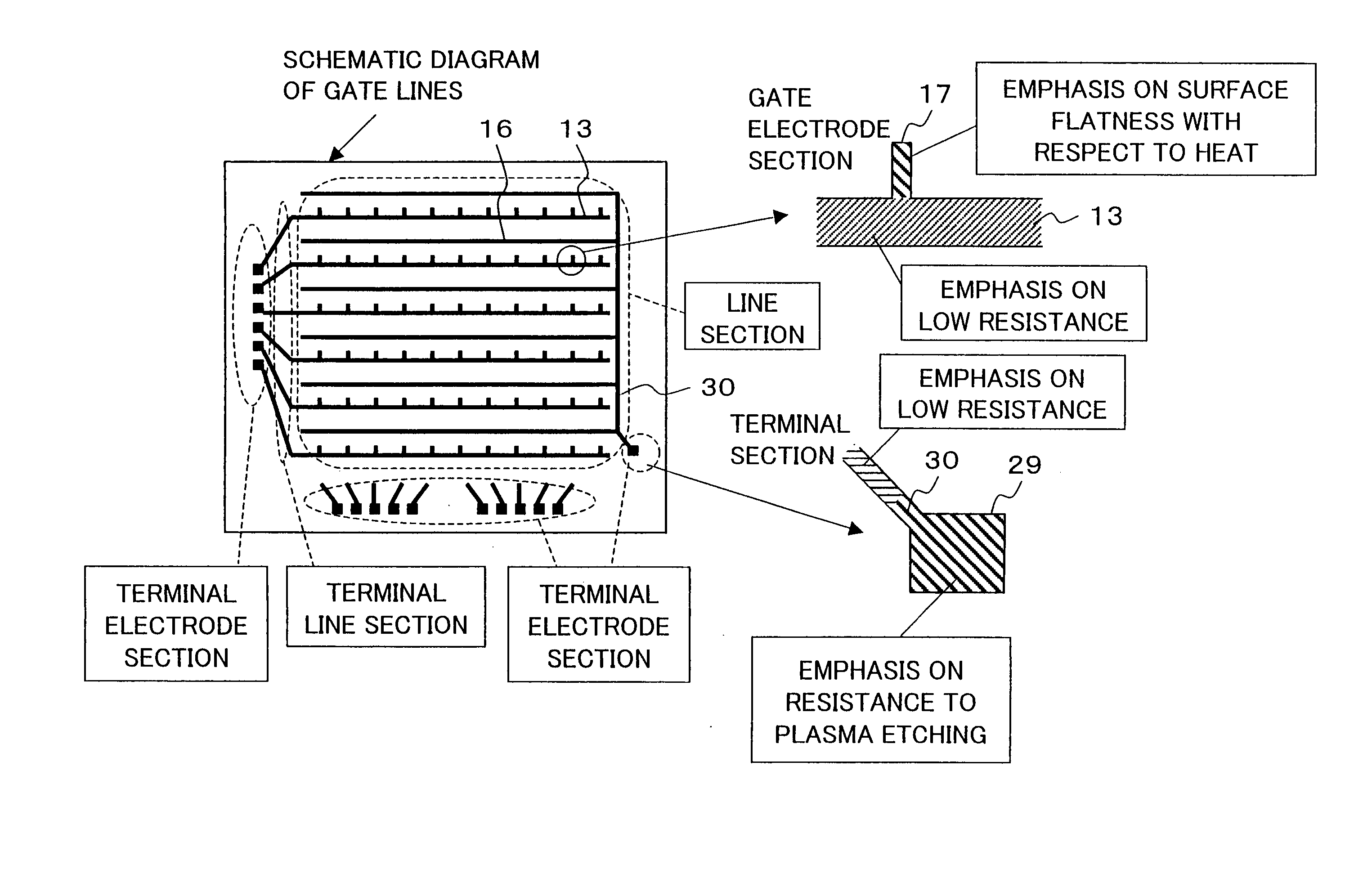

[0271] FIGS. 19(a) and 19(b) show a TFT array substrate 71 in accordance with the...

third embodiment

[0285] [Third Embodiment]

[0286] The following will explain a further embodiment of the present invention.

[0287] In Second Embodiment, the pattern formation equipment typified by ink-jet pattern formation equipment is used in the gate line formation step 102 to separately apply wiring materials having different compositions onto the TFT array substrate 71.

[0288] Note that, constituent elements substantially having the same function as those used in First and Second Embodiments are given the same reference symbols, thus their explanation will be omitted here.

[0289] In the present embodiment, the separate application of the wiring materials having different compositions is performed in the source and drain lines formation step 106, instead of the gate line formation step 102. Here, the wiring materials are arranged such that an amount of indium with respect to silver is 3% by weight in the source electrode 21 and source line 14, and 10% by weight in the drain electrode line 22, for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com