Well cementing material

a well cementing and slurry technology, applied in the direction of ceramicware, solid waste management, sustainable waste treatment, etc., can solve the problems of difficult to combine with conventional cementing materials, mechanical strength degradation, and large increase in the permeability of hardened materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

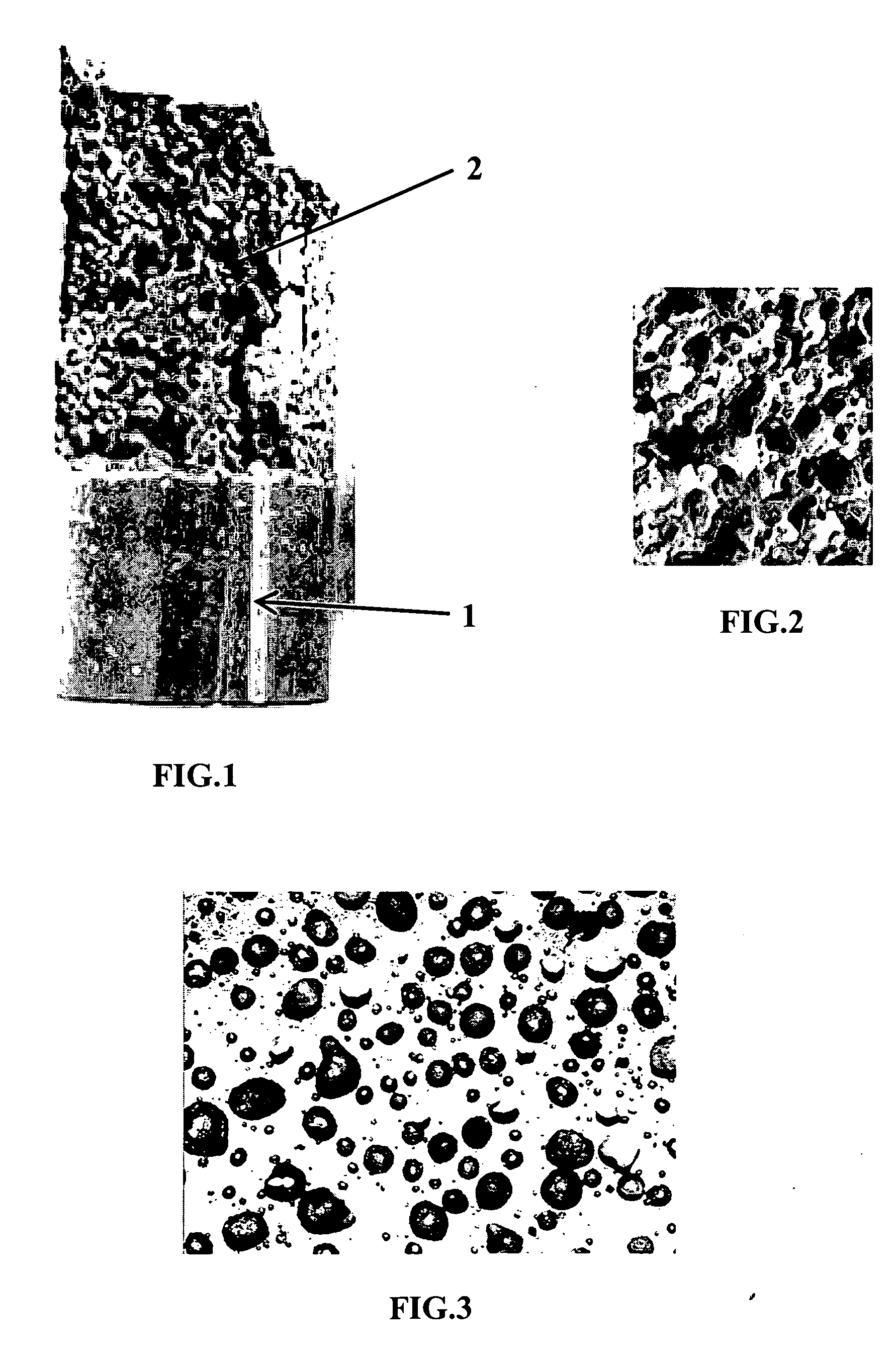

Image

Examples

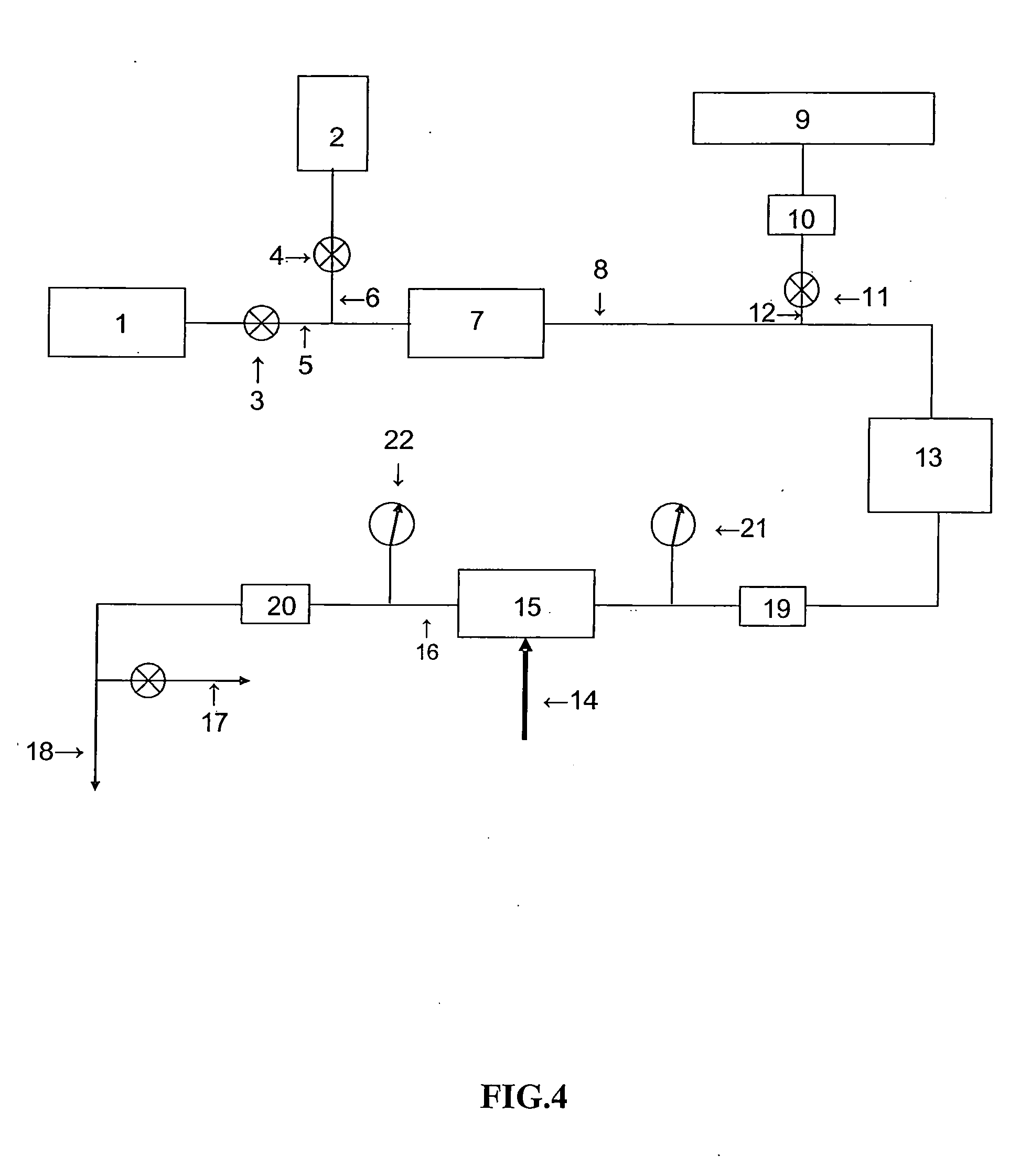

Embodiment Construction

[0043] According to the invention, the low density and the excellent physical properties (compressive strength and permeability) of the cementing material formulations are optimized by combining the following constituents: [0044] a hydraulic binder from the group consisting of the Portland cements and other hydraulic binders, for example of aluminous cement type, whose alumina content is above 30%, or sulfoaluminous cement, or plaster, [0045] a microsilica (also referred to as silica fume) of grain size ranging between 0.1 μm and 30 μm (the BET surface area can range between 10 and 30 m2 / g, preferably 18 m2 / g), whose proportion in the composition according to the invention ranges between 15% and 50% by mass in relation to the mass of hydraulic binder. In the invention, the microsilica can be replaced by fly ash (silico-aluminous, sulfocalcic or silico-calcic particles), [0046] a mineral addition of grain size ranging between 1 μm and 500 μm (which corresponds to a D50 ranging betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com