Polymer electrolyte for a direct oxidation fuel cell, method of preparing the same, and direct oxidation fuel cell comprising the same

a fuel cell and polymer electrolyte technology, applied in the direction of fuel cell details, final product manufacturing, chemical/physical processes, etc., can solve the problems of unreacted fuel lost during operation, change in the surface dimensions of the membrane, and the inability to react with unreacted fuel, etc., to achieve good electrochemical characteristics, reduce cross-over of hydrocarbon fuel, and improve the effect of electrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0108] Solid NAFION® resin was obtained by evaporating commercially available 5 wt % NAFION® / H2O / 2-propanol (Solution Technology Inc., EW=1,100) solution under a vacuum at room temperature while agitating. Cation exchange resin liquid (5 wt % NAFION® / DMAc) was prepared by adding 5 parts by weight of the obtained solid NAFION® resin to 100 parts by weight of dimethylacetamide (Aldrich, DMAc) and agitating mechanically at 100° C. for 24 hours.

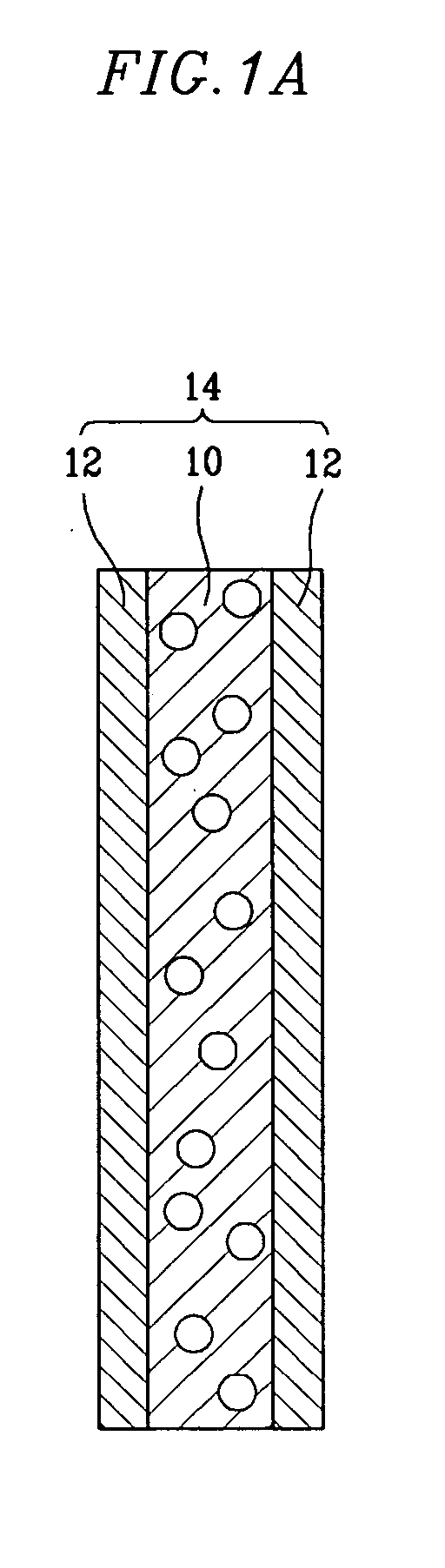

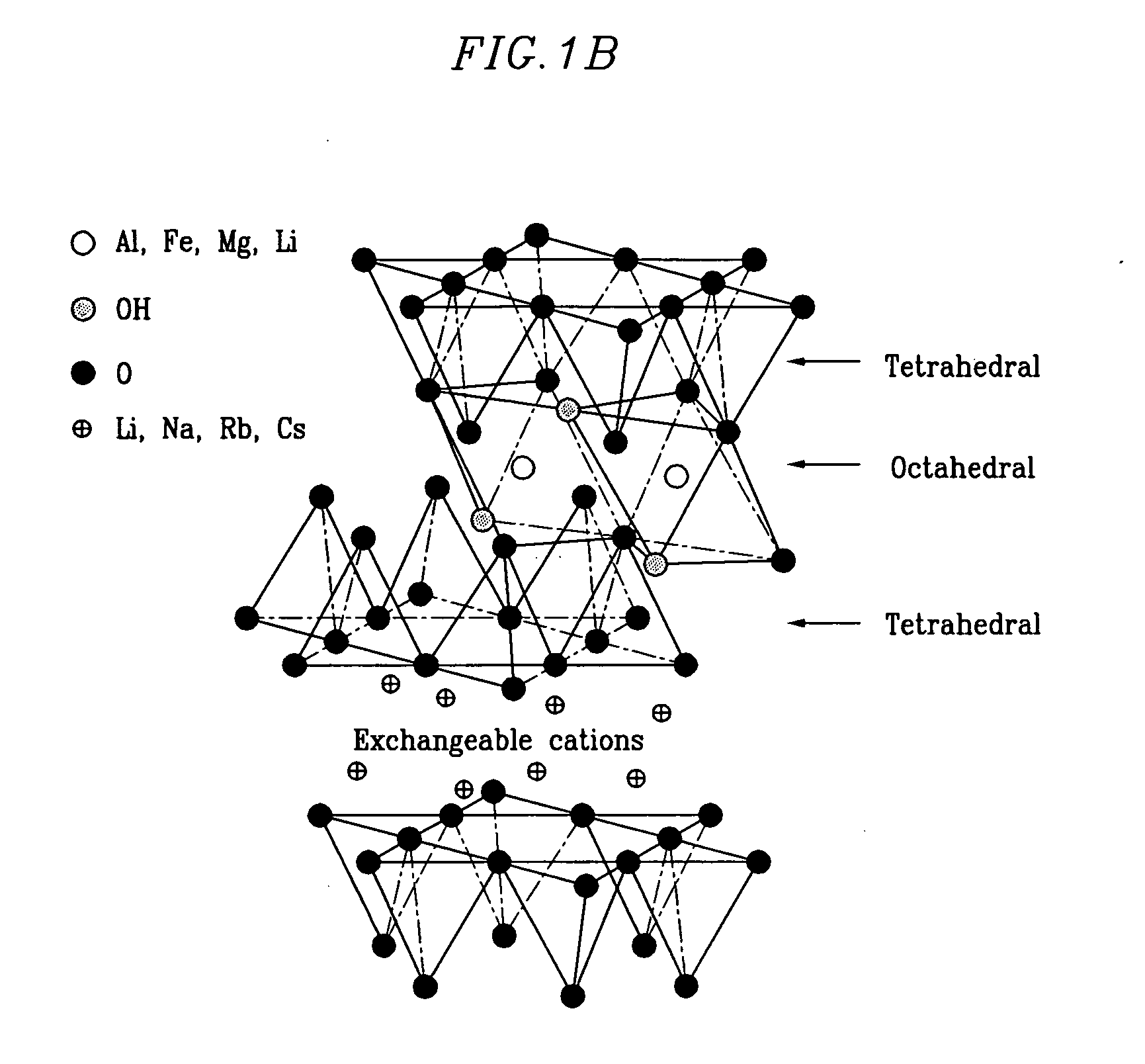

[0109] Montmorillonite treated with an organic modifying agent (Southern Clay Products, Cloisite 10A, with an aspect ratio of 1 / 500 at a state where the organic modifying agents are fully intercalated and with a long-axis length of about 0.3 μm) was added into the cation exchange resin liquid in an amount of 2 parts by weight based on 100 parts by weight of the cation exchange resin. Then, the mixture was mixed by a magnet agitator at 100° C. for 24 hours while applying ultrasound to obtain a cation exchange resin liquid mixture (NAFION®) / MMT / DM...

example 2

[0115] A polymer electrolyte membrane was prepared according to the same method as in Example 1, except that 10 parts by weight of montmorillonite was used based on 100 parts by weight of a cation exchange resin. The weight ratio of cation exchange resin, polymer supporter and montmorillonite in the prepared polymer electrolyte membrane was about 100:13.6:2, which is similar to that of Example 1.

example 3

[0116] A polymer electrolyte membrane was prepared according to the same method as in Example 1, except that kaolinite was mixed with the cation exchange resin liquid obtained in Example 1 to prepare the cation exchange resin liquid mixture. The weight ratio of cation exchange resin, polymer supporter and kaolinite in the prepared polymer electrolyte membrane was about 100:13.6:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com