Radiant heat pump device and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

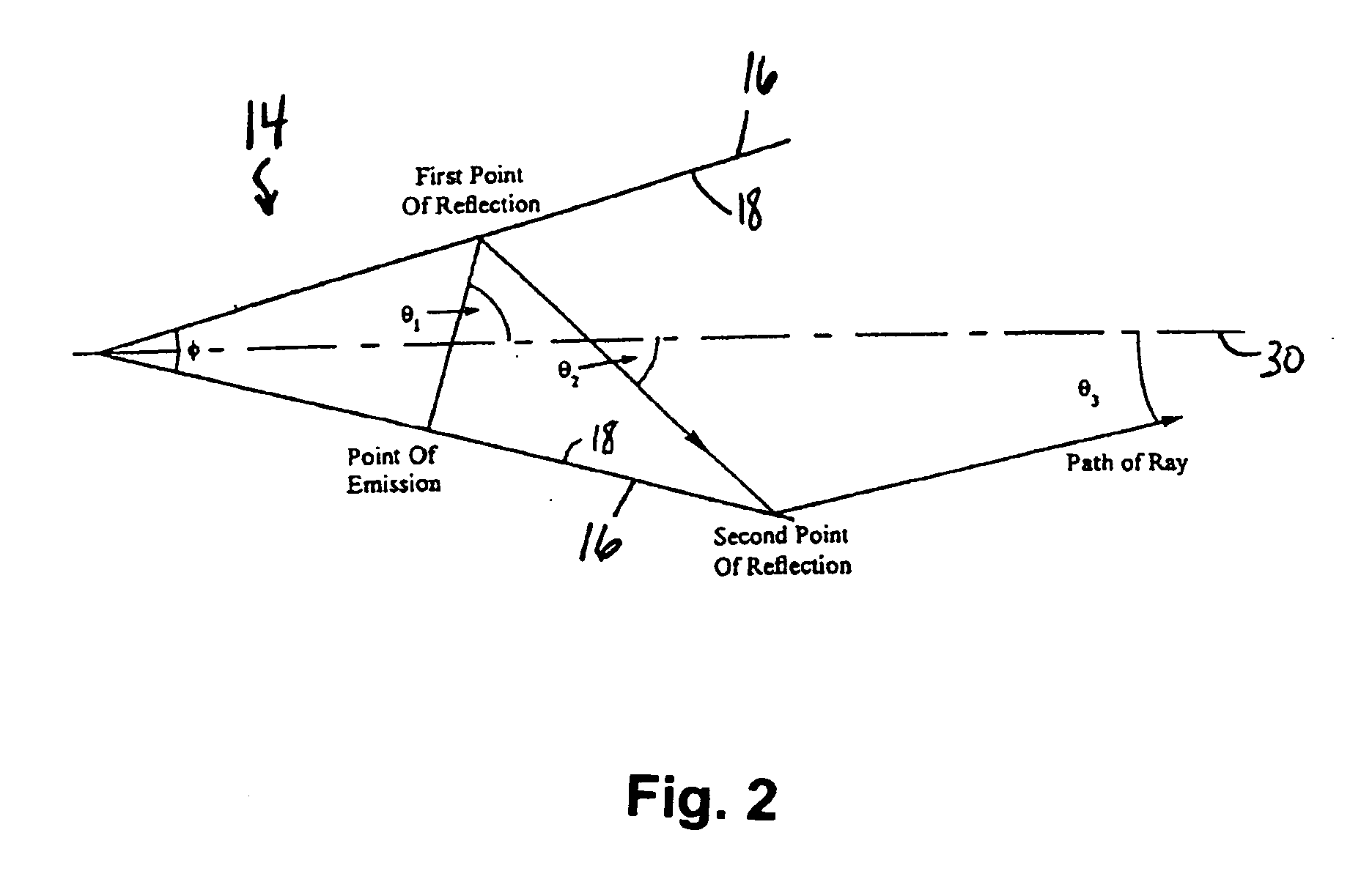

[0045] Those skilled in the art will know that unlike heat conduction and convection, radiant heat transfer between two bodies involves an independent, quantifiable flow in each direction. Conventional theory on radiant heat transfer is based on an ideal surface, known as the blackbody. The blackbody has a total emissive power which is proportional to the fourth power of its absolute temperature, emits uniformly (diffusely) in all directions, emits with a characteristic, predictable wavelength distribution and absorbs all radiant energy which is incident upon it.

[0046] A less idealized theoretical surface than a blackbody is termed a graybody which also emits diffusely and with a characteristic wavelength distribution. However, a graybody only emits a fraction of the power of a blackbody; that fraction (uniform for all wavelengths) is termed its emissivity. Conversely, a graybody also absorbs only a fraction of the incident radiant energy; that fraction (uniform for all wavelengths...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com