Method for producing a lithium secondary battery

a secondary battery and lithium ion battery technology, applied in secondary cell manufacturing, cell components, nickel accumulators, etc., can solve the problems of difficult to achieve high energy density of lithium ion batteries, and generation of dendrites of lithium (tree branch-like crystals). achieve the effect of long cycle li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1-1

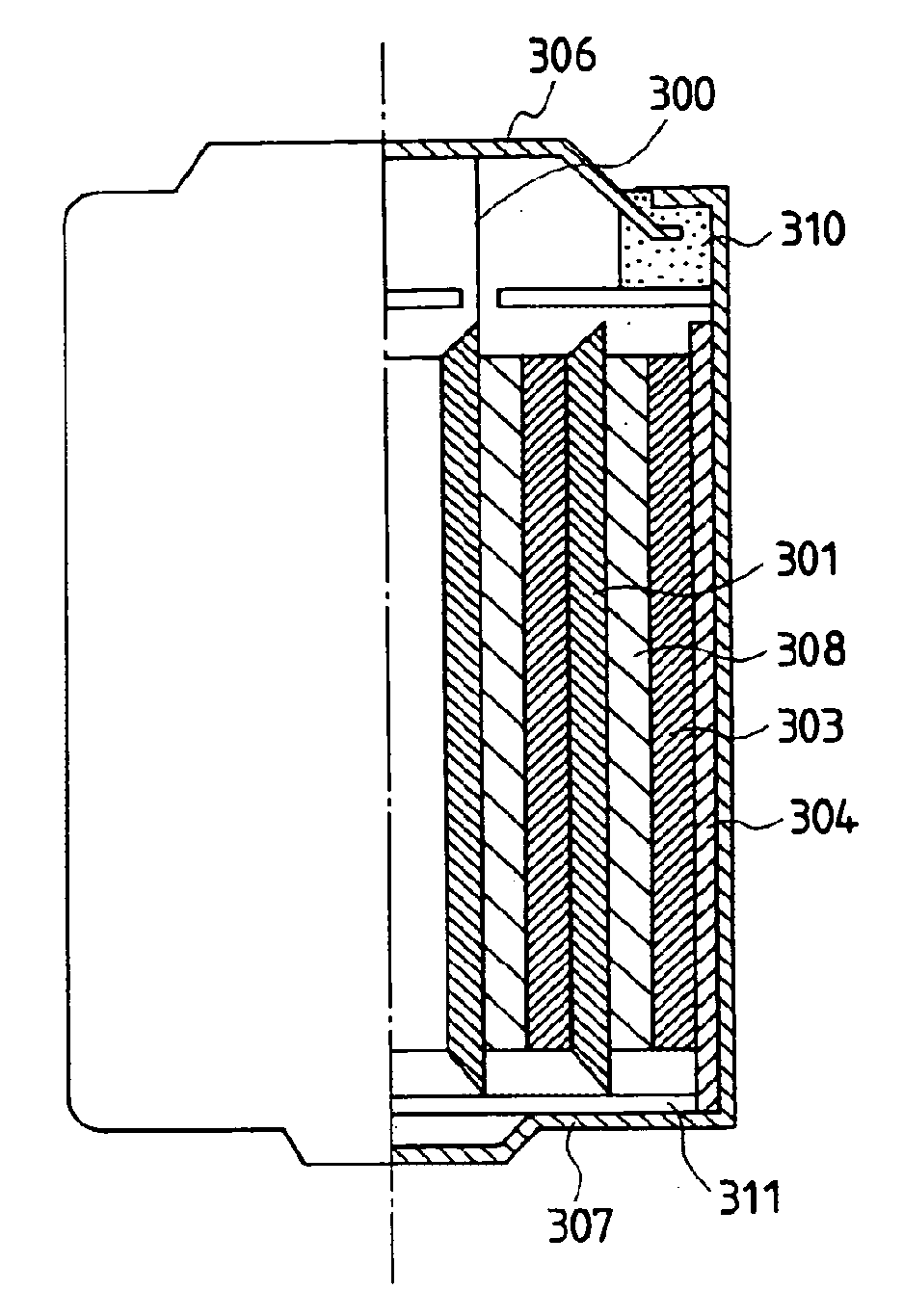

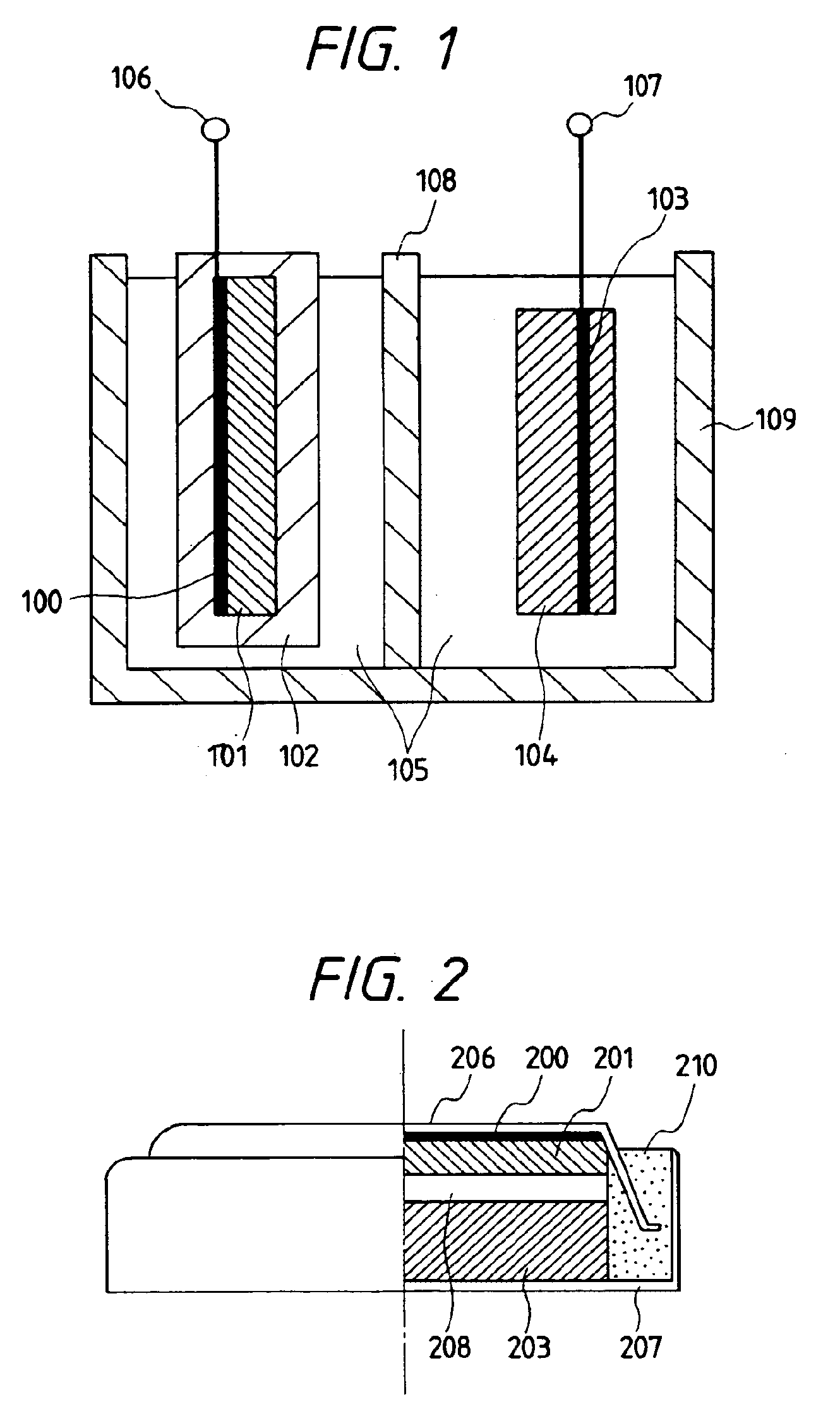

[0416] A flat type battery having a simple structure, exhibiting assembling easiness and having a cross-sectional structure schematically shown in FIG. 2 was assembled to evaluate the characteristics of the secondary battery while mainly evaluating the life against cycle operation.

[0417] First, a solution in which colloidal silica manufactured by Shokubai Kasei and subjected to hydrophobic treatment in an atmosphere of dry argon gas was dispersed in N,N-dimethylformamide was dehydrated by active alumina. Then, lithium metal foil to which titanium mesh collector 200 was pressed against the reverse side was immersed in the colloidal silica solution prepared by the foregoing method, and then dried at 120° C. so that a lithium negative pole 201 covered with silica was manufactured.

[0418] A positive pole activating material 203 was manufactured in such a manner that a mixture of dehydrated and electrolyzed manganese dioxide and lithium carbonate was heated so that a lithium-manganese c...

example 1-2

[0423] A battery similar to that according to Example 1-1 was manufactured.

[0424] The preparation of the materials and assembly were performed in an atmosphere of dry argon similarly to Example 1-1.

[0425] First, aluminum trichloride and phosphoric acid were allowed to react with each other in ethyl alcohol, and gradually heated to 100° C. so that glass-form aluminum phosphate was obtained. Then, it was dispersed in n-hexane so that a film forming solution was prepared. The film forming solution was applied to a lithium metal foil to which the titanium mesh collector was pressed. Then, a film was formed at 120° C. Then, similar processes to those according to Example 1-1 were performed so that a lithium battery was manufactured.

example 1-3

[0426] A battery similar to that according to Example 1-1 was manufactured.

[0427] The preparation of the materials and assembly were performed in an atmosphere of dry argon similarly to Example 1-1.

[0428] First, acetic acid and water were added to an ethyl alcohol solution of tetrabutoxytitanium to be hydrolyzed. Then, diethylamine was added so that colloidal titanium oxide was formed. Then, colloidal titanium oxide was dissolved in a xylene solution of polyethylene so that a film forming solution was prepared. The film forming solution was applied to the lithium metal foil to which the stainless mesh collector was pressed followed by drying it at 1000° C. Then, electron beams were applied to crosslink the polyethylene so that a film was formed. Then, similar processes to those according to Example 1-1 were performed so that a lithium battery was manufactured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com