Compositions of gas generates with polymer adhesive

a technology of gas generants and adhesives, which is applied in the field of chemical compositions, can solve the problems of reducing the cost of the filter, producing tolerable levels of toxic gases, etc., and achieves the effects of improving the quality of pellets, reproducibility, and radial tensile strength and axial tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

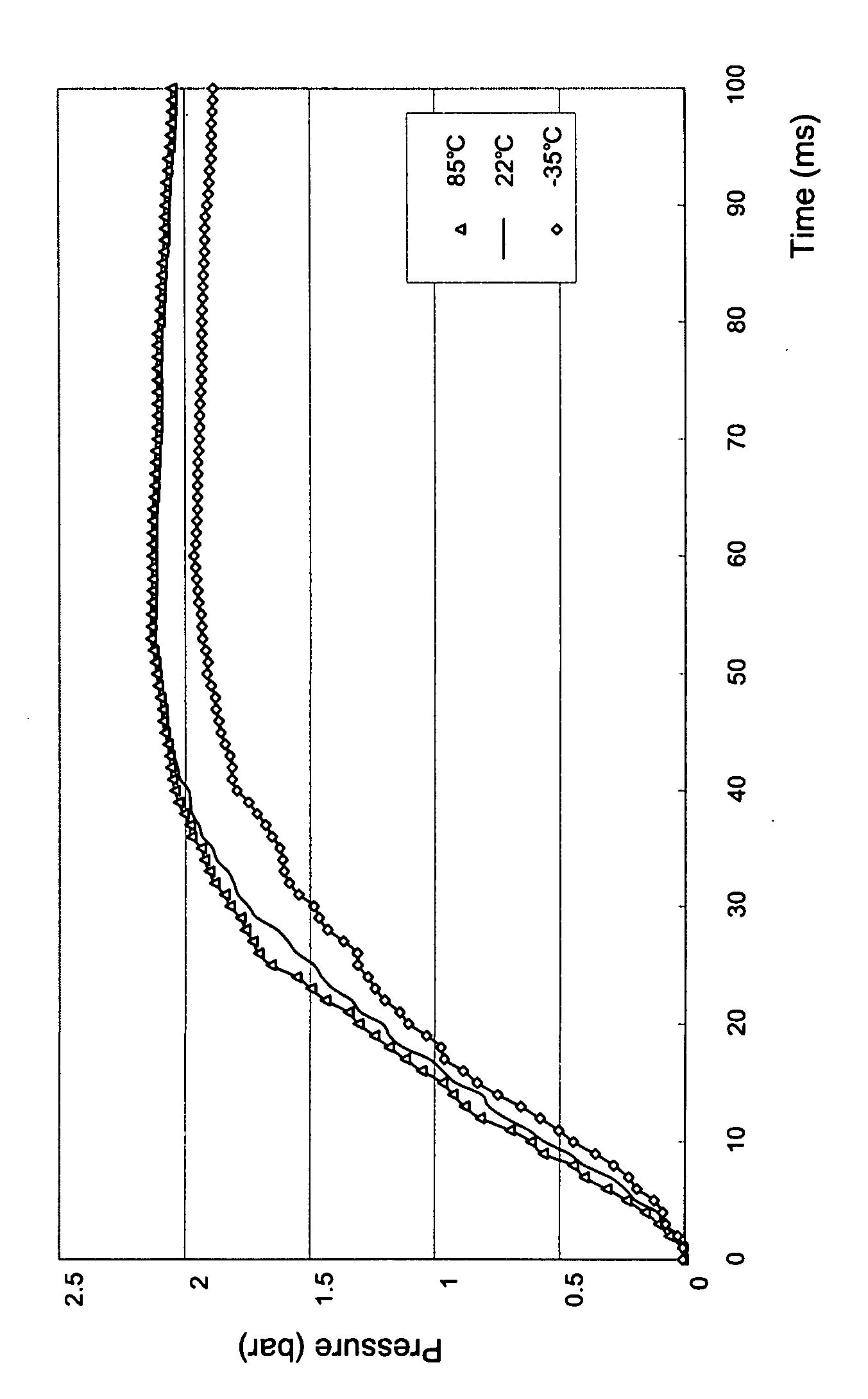

Image

Examples

example 1

[0026]The gas generant composition is prepared by taking 10 gm vinyl alcohol acetate resin in a stirring machine, dissolving it into 1000 ml industrial alcohol, adding 70 gm silicon dioxide with average diameter of 10 nm, 350 gm nitroguanidine with average diameter of 5 μm, 190 gm 5-aminotetrazole with average diameter of 10 μm, 305 gm potassium nitrate with average diameter of 20 μm, and 75 gm potassium perchlorate with average diameter of 10 μm in order, stirring the mixture into p aste, heating the paste at 60° C., stirring continuously until the industrial alcohol evaporates, using a screen with screen sizing of 425 μm to crush the product, heating the mixture in an oven setting at 105° C. for 24 hours, then the dried mixture is cooled down to room temperature. The dried mixture is pressed into pellets with 6 cm diameter×4 cm height by a pelletizing machine. The radial tensile strength of the pellet is 16 kg / cm2 and the axial tensile strength of the pellet is 15 kg / cm2.

[0027]The...

example 2

[0029]The manufacturing processes of this example are the same with above one while the VAAR is replaced by starch. The combustion temperature, carbon monoxide concentration and carbon dioxide concentration of this example are all higher than those of the example one.

example 3-5

[0030]Gas generant compositions are formulated according to table 2 below (amounts in parts by weight). As shown in table 2, the amounts of potassium nitrate and potassium perchlorate are different in different examples.

TABLE 2componentExample 3Example 4Example 5nitroguanidine33%33%33%5-aminotetrazole23%23%23%potassium nitrate35%30%25%potassium 0% 5%10%perchloratesilicon dioxide8.6% 8.6% 8.6% (SiO2)vinyl alcohol0.4% 0.4% 0.4% acetate resin(VAAR)combustion1910 K1929 K2001 Ktemperaturecarbon monoxide7.49E−27.70E−27.95E−2concentrationcarbon dioxide5.72E−26.27E−26.78E−2concentration

[0031]The combustion temperature, carbon monoxide concentration and carbon dioxide concentration are calculated by the computer program CEC76 of NASA (National Aeronautics and Space Administration).

[0032]The manufacturing processes of these examples are the same with the example one. The potassium perchlorate contains more oxygen than the potassium nitrate so that the gas generant with more potassium perchlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com