Microbial pre-treatment of double refractory gold ores

a biological process and gold ores technology, applied in the field of biological processes for recovering, can solve the problems of reducing the adsorption capacity of ores, reducing the quantity of gold, and the technique not working for ores, so as to reduce the selective activity or function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

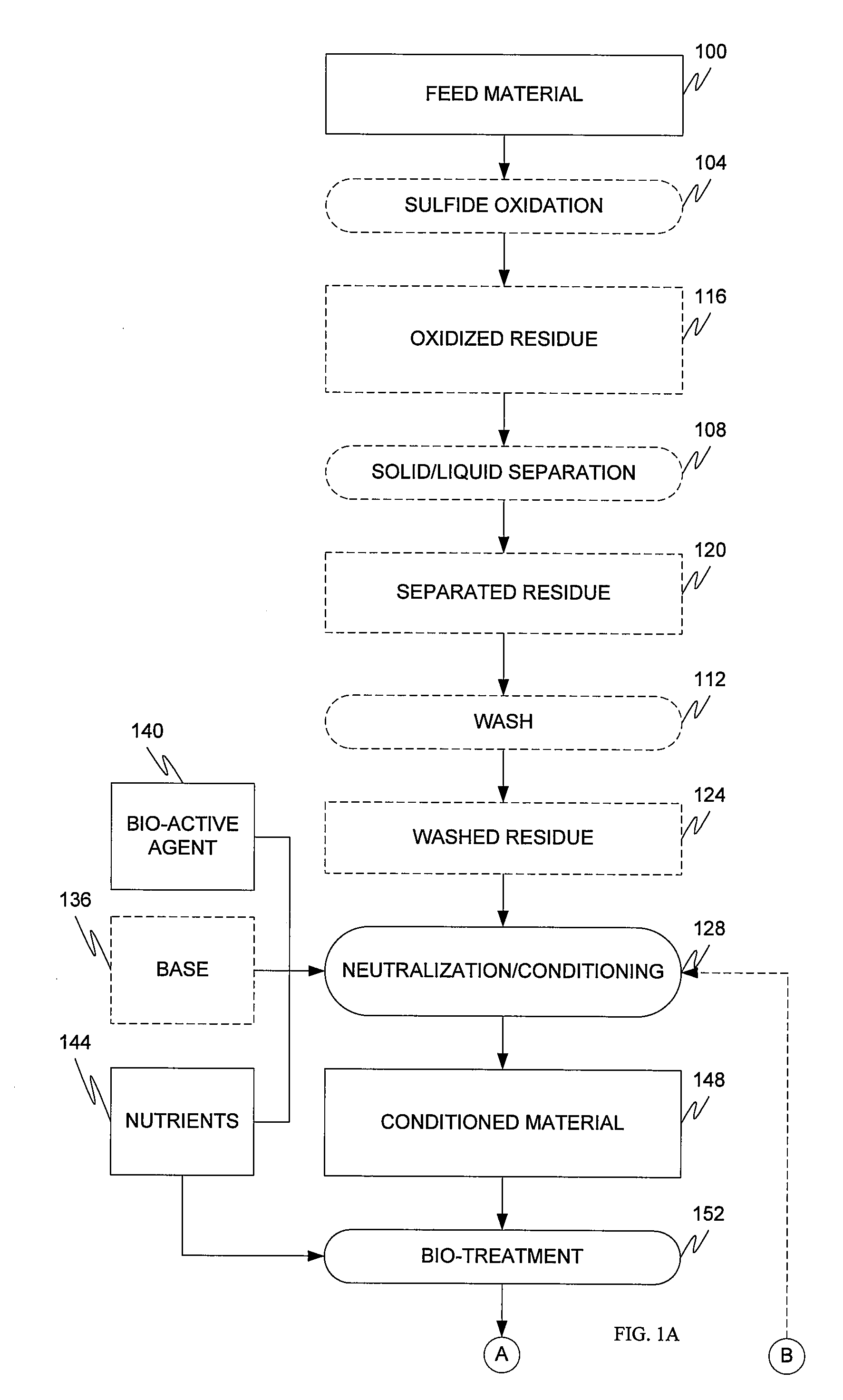

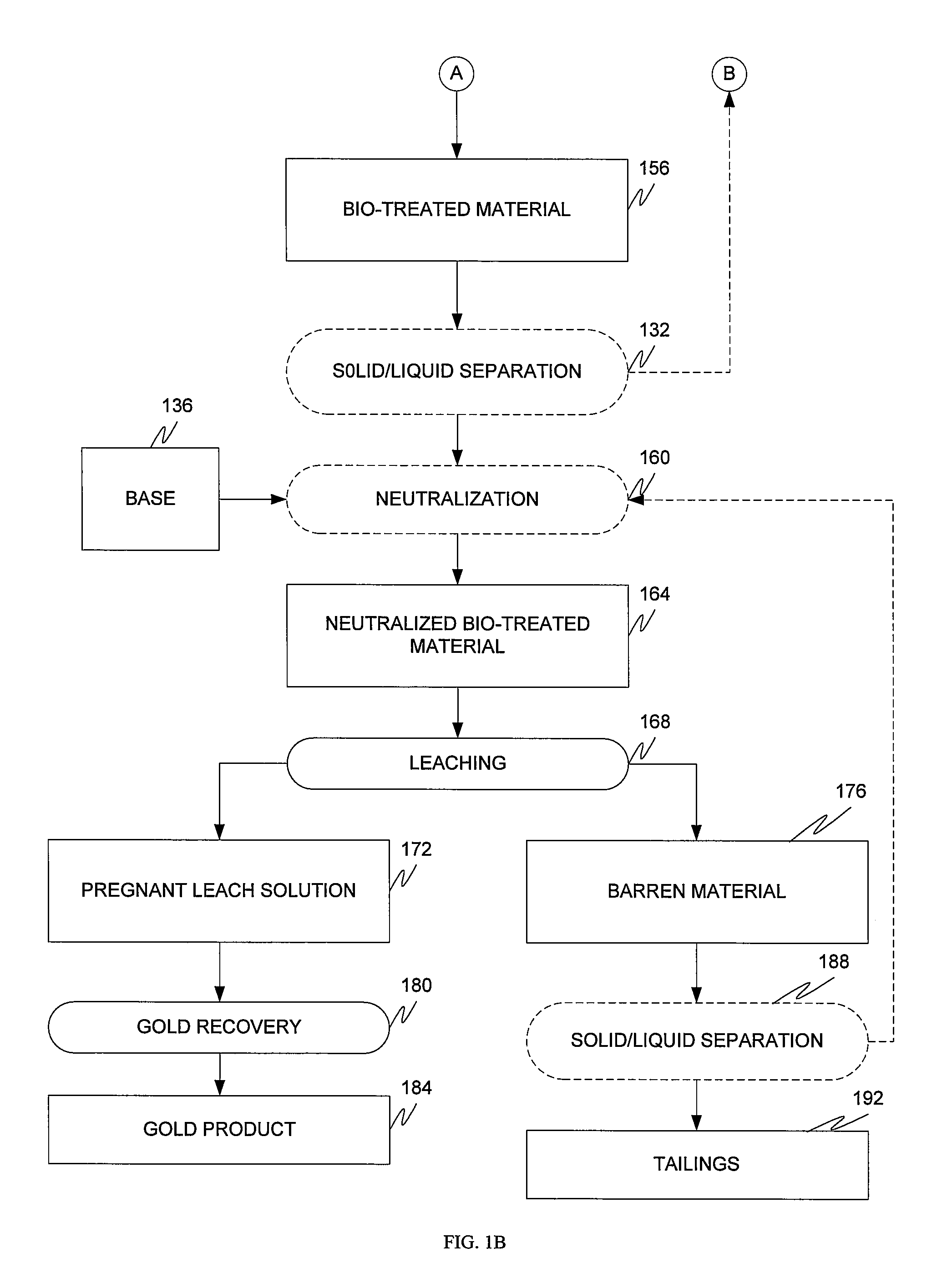

Method used

Image

Examples

example 1

Baseline Cyanidation

[0066]Three different ore samples were employed to investigate the two stage bio-oxidation-bio-treatment process. The analysis is shown in Table 1. Sample A is a flotation concentrate. Samples B and C are run-of-mine ore samples.

TABLE 1Analysis of Ore SamplesAuAgCPreg-Sampleg / tg / t(graphitic) %S %Fe %As %Robbing %A76.16.007.0313.3015.301.1251.8B4.800.243.000.692.250.6268.9C2.910.102.363.796.361.4980.3

[0067]Conventional bottle roll cyanidation tests were conducted using (75% minus 75 micron ore), 0.5 g / l NaCN, at a pH of 10.5, for 24 hours. The results presented in Table 2 show that gold extractions for each sample were less than 22%. The sulfide and inorganic carbon contents of the ore and the low gold recovery by cyanidation indicate the samples are double refractory ores.

TABLE 2Results of Straight CyanidationSample% AuResidueConsumption, kg / tNo.Extractiong / t, AuNaCNCaOA21.559.745.623.85B17.73.951.841.42C15.02.471.741.37

example 2

Bio-Oxidation

[0068]The same feed samples employed in Example 1 were pre-treated using microbial bio-oxidation for the treatment of the refractory sulfidic component of the ore. The pretreatment consisted of grinding the ores to 90% minus 200 mesh (74 μm) and forming a slurry of about 20% solids in a 2 liter Erlenmeyer flask. The pH's of the slurries were adjusted to about pH 1.5 with sulfuric acid. The chemolithotrophic bacteria used for sulfide oxidation was a mixture of equal parts Acidithiobacillus ferrooxidans, Acidithiobacillus thiooxidans and Leptospirillum ferrooxidans. These chemolithotrophes were grown together to form a mixed culture and maintained in a medium containing about 0.5 g / l of (NH4)2SO4, K2HPO4, MgSO4.7H2O, 0.1 g / l KCl and 0.01 g / l CaNO3, 15.0 g / l FeSO4.7H2O, 1.0 g / l sulfur and 0.25 ml / l of Wolfe's solution. A 10% v / v microbial culture was added into the flask containing the pH adjusted slurry, and was agitated using an orbital shaker at 180 rpm for 14 days. At ...

example 3

Bio-Treatment of Carbonaceous Preg Robbing Material

[0070]The same feed samples used in Examples 1 and 2 were pre-treated with one stage microbial oxidation for treatment of preg robbing carbonaceous materials, followed by the conventional bottle roll cyanidation as described in Example 1. White rot fungus was used for deactivation of the carbonaceous material.

[0071]The white rot fungus, Trametes versicolor, was cultured in a medium containing Kirk's medium, agar and malt extract. The 1,000 ml Kirk's solution contained about 10.1 grams glucose, 0.44˜0.80 grams ammonium tartrate, 0.05 gram MnSO4.7H2O, 0.01 gram CaCl2.2H2O, 10 μml thiamine, 100 μml trace minerals and 2.92 gram 2.2 dimethylsucicinate supplement.

[0072]Pretreatment of the samples included grinding the ore to 90% minus 200 mesh (74 μm) and forming a slurry of 20% solids in a 2 liter Erlenmeyer flask. A 10% v / v microbial culture of Trametes versicolor was added into the flask containing the pH 9.5 slurry, which was agitated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com