Non-volatile memory cell and fabrication method thereof

a technology of memory cells and fabrication methods, applied in the direction of digital storage, instruments, electrical equipment, etc., can solve the problems of significant differences in the wording voltage and current between different memory cells, voltage and metal materials, etc., and achieve the effect of increasing the uniformity of controlling different memory cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

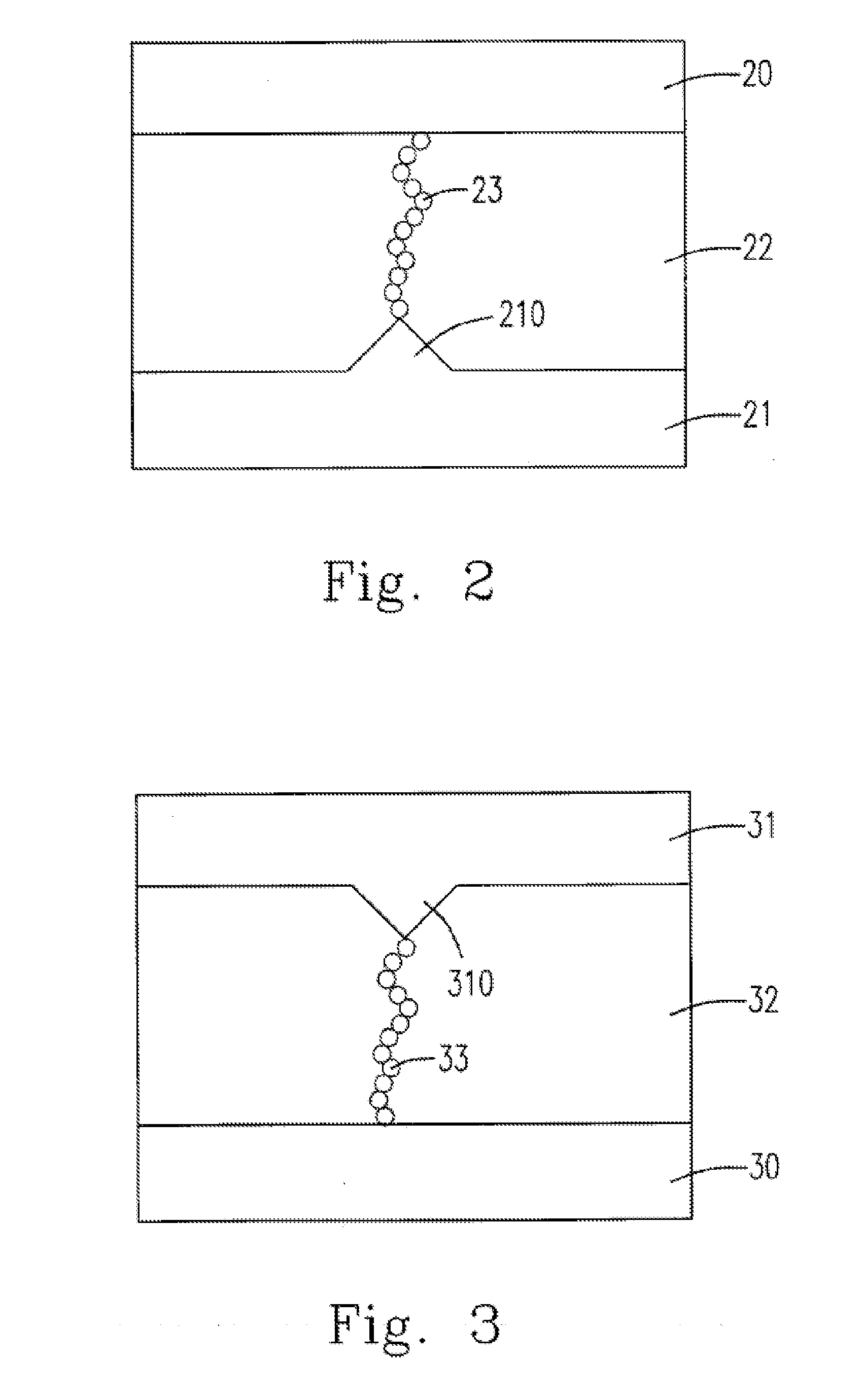

[0051]Please refer to FIG. 2, which is a diagram showing the side view of a non-volatile memory cell according to the present invention. As shown in FIG. 2, the top electrode is an oxidizable electrode 20 where the oxidation and the reduction reactions will take place when a sufficient working voltage is applied thereto, the bottom electrode is an inert electrode 21, and what is deposited between the top and the bottom electrodes is an ion conductor 22. The inert electrode 21 has a bulging terminal 210, which is a closest area to the oxidizable electrode 20, on a surface facing the oxidizable electrode 20. The surface area of the bulging terminal 210 contacting with the ion conductor 22 is smaller than the remaining area of the abovementioned surface facing the oxidizable electrode 20. During the writing process, the oxidizable electrode 20 is an anode and the inert electrode 21 is a cathode. When a sufficient negative voltage is supplied to the inert electrode 21, since the bulging...

second embodiment

[0054]Please refer to FIGS. 4A-4E, which are diagrams showing a fabrication method of the present invention. As shown in FIGS. 4A-4E, simplified plane processes are provided for fabricating the non-volatile memory cell of the present invention. At first, a patterned structure composed of an oxidizable electrode 30, an ion conductor 32, a hard mask 34 and a photoresist layer 35 is formed (shown in FIG. 4A), wherein the patterning process includes lithography and etching processes for transferring a predefined pattern to the abovementioned structure. The lithography process includes the coating of the photoresist layer 35, the soft baking, the mask align, the exposure, the post exposure baking, the development, the hard baking, and the dissolution of the photoresist layer 35. The etching process could be a wet etching, a dry etching, a reactive ion-beam etching or other suitable etching processes. The hard mask 34 is a silicon oxide layer, a silicon nitride layer, a silicon oxynitride...

third embodiment

[0055]Please refer to FIGS. 5A-5E, which are diagrams showing a fabrication method of the present invention. As shown in FIG. 5A, first of all, an oxide layer 53 is deposited on an inert electrode 51 serving as the bottom electrode and merely covers partial of the top surface of the inert electrode 51. Afterward, a metal layer 54 having a material the same as that of the inert electrode 51 is deposited on the structure disclosed in FIG. 5A by a suitable deposition process and covers all exposed portions of the oxide layer 53 and the uncovered top surface of the inert electrode 51 (as shown in FIG. 5B). Subsequently, after the metal layer 54 is etched back by using a back-etching method, portions of the metal layer 54 remain on the sidewalls of the exposed oxide layer 53 (as shown in FIG. 5C), wherein the back-etching method is an anisotropic etching method, e.g. the dry etching including plasma etching, reactive ion etching and so on. Subsequently, the procedure of removing the oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com