Sb-Te-Based Alloy Sintered Compact Sputtering Target

a technology of compact sputtering target and te-based alloy, which is applied in the direction of diaphragms, metallic material coating processes, and recording information storage, etc., can solve the problems of affecting the film affecting the quality and yield of the thin film as the recording medium, and affecting the quality of the sputtered film. , to achieve the effect of improving the uniformity of the sputtered film, preventing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

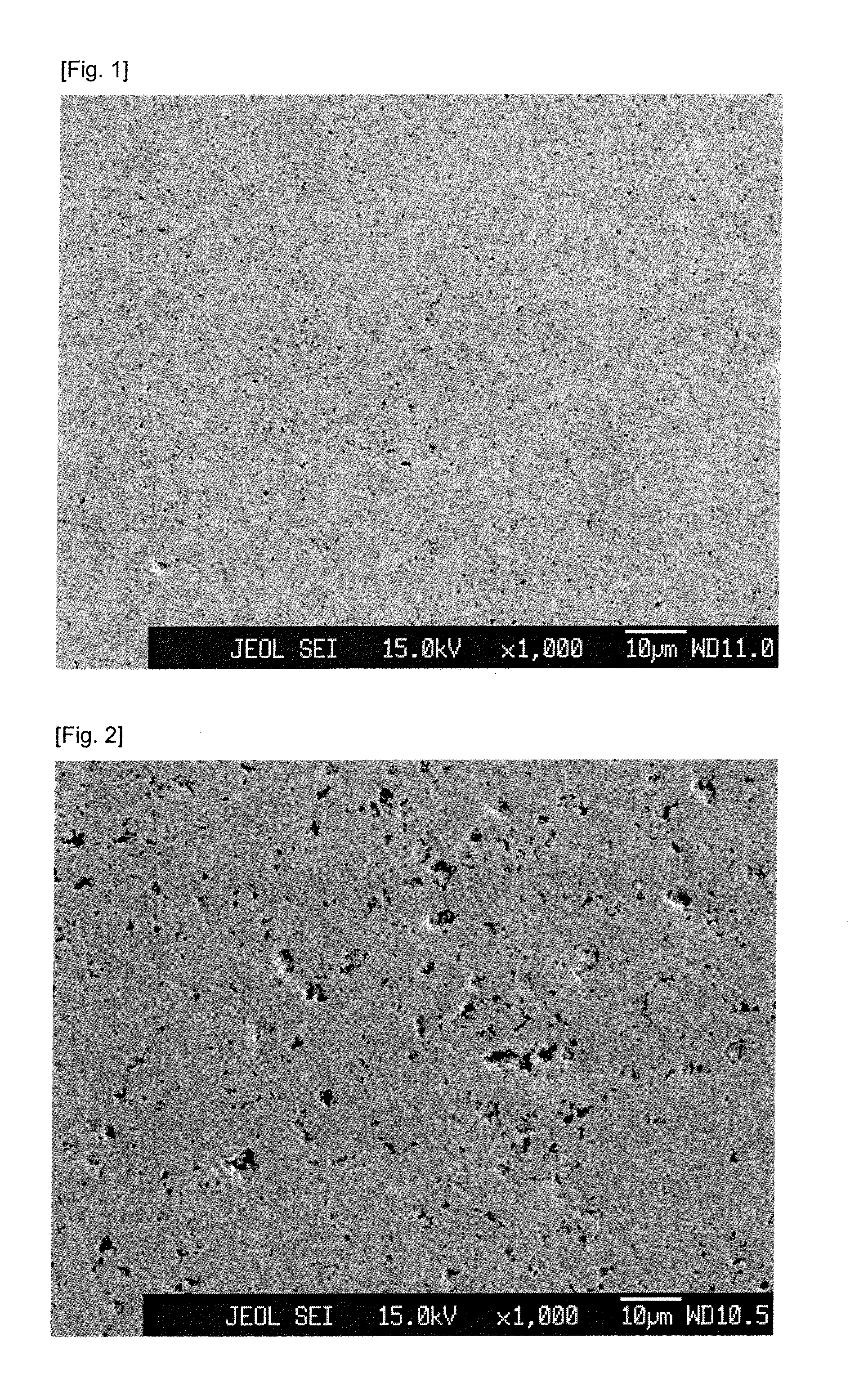

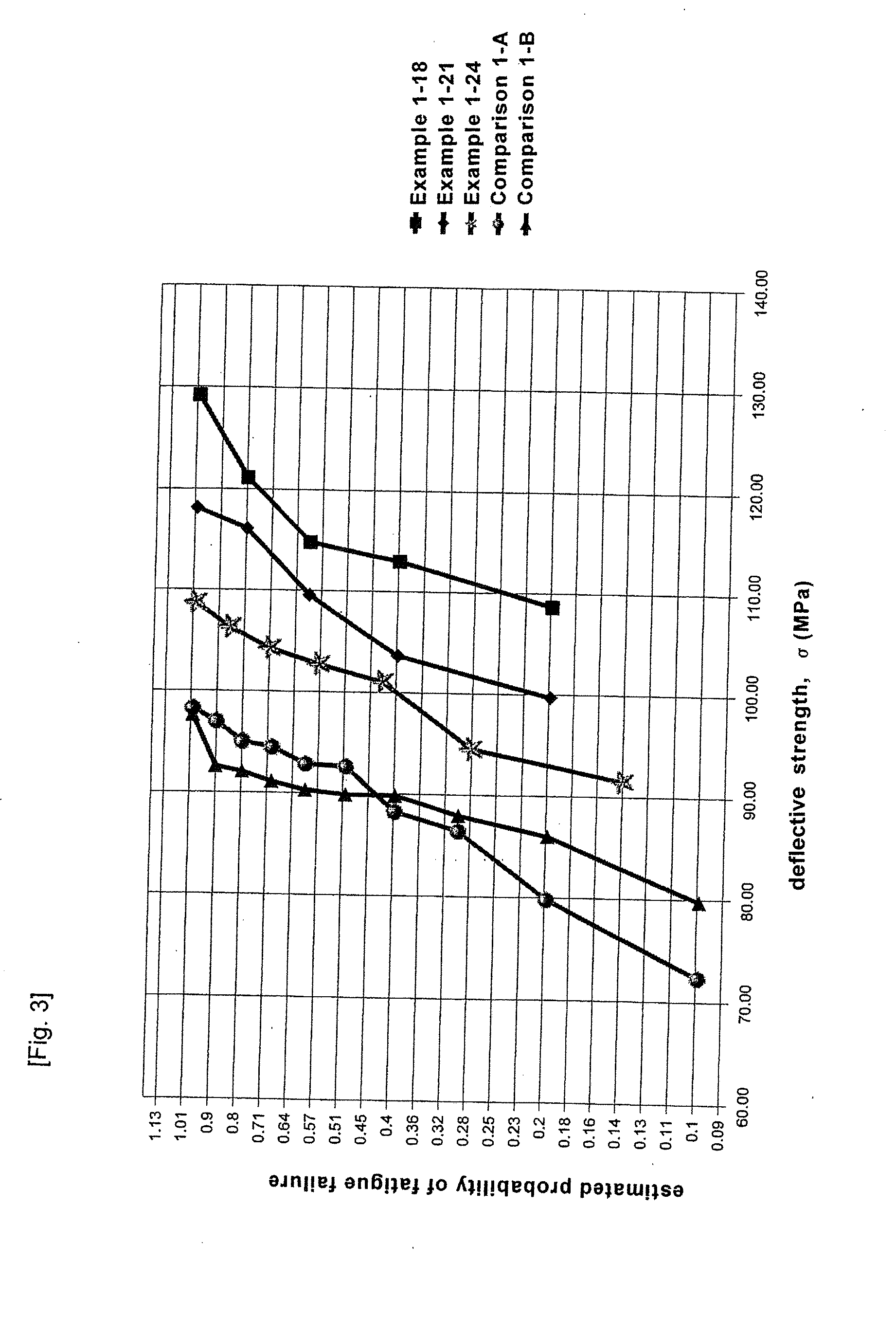

[0071]Ge, Sb, Te powder raw materials respectively having a purity of 4N or higher excluding gas components were mixed and synthesized to achieve a Ge22.2Sb22.2Te55.6 alloy and this alloy raw material was pulverized with a jet mill pulverizer in an argon inert atmosphere. Powder (P) having an average diameter of 3 μm or less was thereby obtained.

[0072]Subsequently, carbon powder (C) having a grain size of 20 to 750 nm was mixed with the powder (P) at the prescribed mixing ratios (0.1 to 30 at %) shown in Table 1 using a mortar, a planetary ball mill, and a vibrational mill.

[0073]This mixing ratio must be set within an appropriate range. If this is deviated; that is, if the mixing ratio is less than 0.1 at %, there will be no effect of adding the carbon powder (C). Contrarily, if the addition exceeds 30 at %, the mechanical strength will diminish due to the deterioration in the density of the sintered compact, and problems such as fractures occurring in the production process or sput...

example 2

[0088]As with Example 1 above, Ge, Sb, Te powder raw materials respectively having a purity of 4N or higher excluding gas components were mixed and synthesized to achieve a Ge22.2Sb22.2Te55.6 alloy, and this alloy raw material was pulverized with a jet mill pulverizer in an argon inert atmosphere. Powder (P) having an average diameter of 3 μm or less was thereby obtained.

[0089]Subsequently, boron powder (B) having a grain size of 20 to 750 nm was mixed with the powder (P) at the mixing ratios (0.1 to 30 at %) shown in Table 3 using a mortar, a planetary ball mill, and a vibrational mill.

[0090]This mixing ratio must be set within an appropriate range. If this is deviated; that is, if the mixing ratio is less than 0.1 at %, there will be no effect of adding the boron powder (B). Contrarily, if the addition exceeds 30 at %, the mechanical strength will diminish due to the deterioration in the density of the sintered compact, and problems such as fractures occurring in the production pr...

example 3

Part of Comparative Example 3

[0102]In, Sb, Te powder raw materials respectively having a purity of 4N or higher excluding gas components were mixed and synthesized to achieve an In22.2Sb22.2Te55.6 alloy, and this alloy raw material was pulverized with a jet mill pulverizer in an argon inert atmosphere. Powder (P) having an average diameter of 3 μm or less was thereby obtained.

[0103]Subsequently, carbon powder (C) and boron powder (B) having a grain size of 7 to 750 nm was mixed with the powder (P) at the mixing ratios (0.1 to 30 at %) shown in Table 5 using a mortar.

[0104]This mixing ratio must be set within an appropriate range. If this is deviated; that is, if the mixing ratio is less than 0.1 at %, there will be no effect of adding the carbon powder (C) and boron powder (B). Contrarily, if the addition exceeds 30 at %, the mechanical strength will diminish due to the deterioration in the density of the sintered compact, and problems such as fractures occurring in the production p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com