System for performing laser filamentation within transparent materials

a technology of transparent materials and lasers, applied in glass making apparatus, manufacturing tools, welding/soldering/cutting articles, etc., can solve the problems of increased production cost, increased cleaning and polishing steps, and poor quality edges, so as to facilitate active control of the process and facilitate the formation of filament arrays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Singulation of Glass Samples Via Laser Filamentation

[0244]To demonstrate some of the embodiments disclosed above, glass samples were processed on a laser system equipped with a 50W ps laser operating at high rep rate (>400 kHz) to facilitate very rapid scans of the laser beam across the target, with stages moving at a rate of approximately 500 mm / s—1000 mm / s, where 0.7 mm thick Gorilla glass had been mounted. The laser, operating at the fundamental, 1064 nm with a pulse width less than 25 ps, was set to operate in burst mode with 20 sub-pulses in a burst.

[0245]Both rectilinear cuts and curvilinear shapes have been achieved at high speed with very good edge quality and high bend strength. For example, samples of Gorilla thus processed have shown >110 MPa as-cut bend strength. FIG. 19 shows a micrograph of the facet edge after formation of the modified zone (the so-called scribe step) and the cleave step (singulation). The roughness shown is less than 10 μm RMS over a substantial port...

example 2

Formation of 6 mm Long Filaments in Glass Substrates

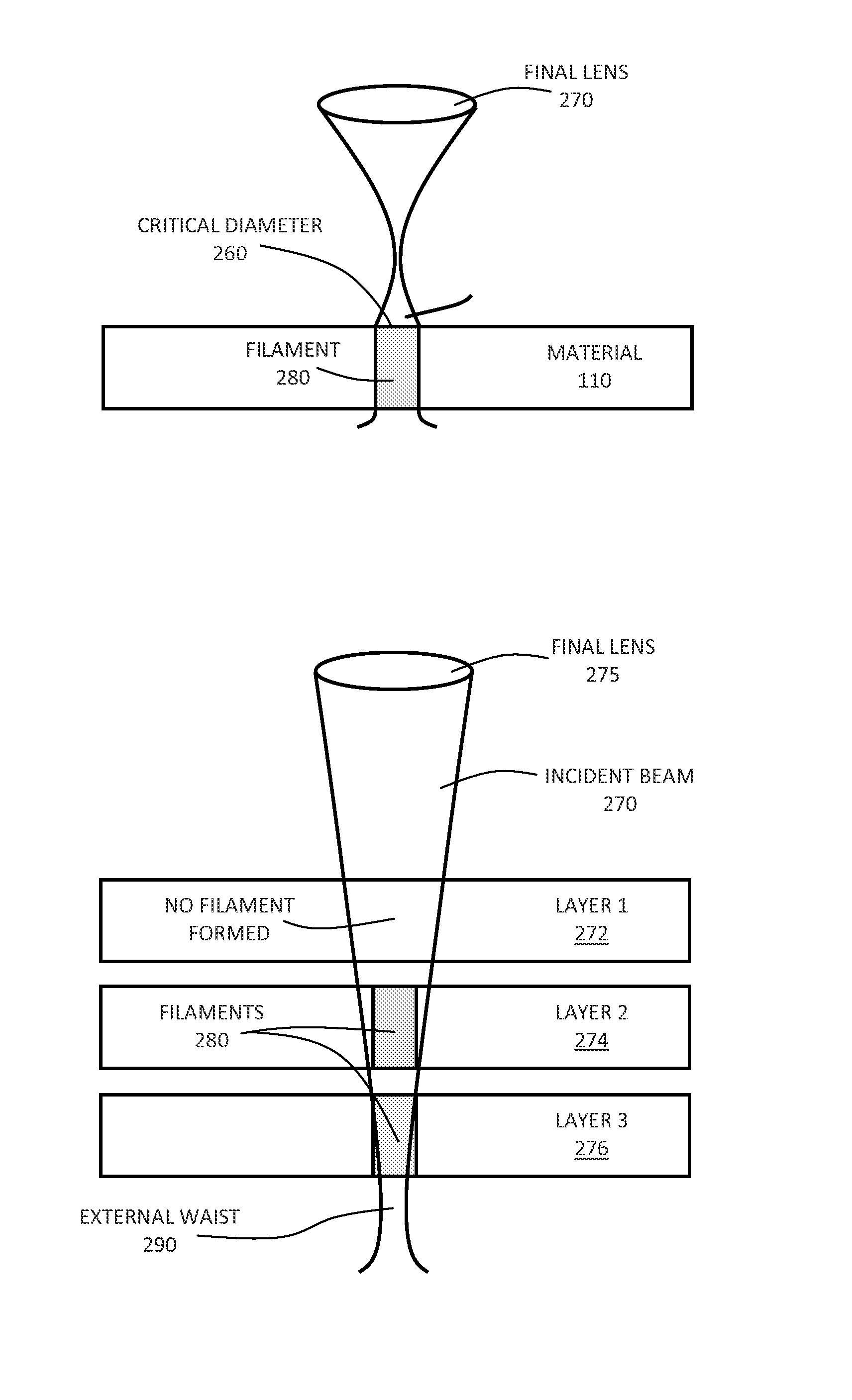

[0255]In one example implementation, the laser beam may include a burst of pulses having a pulse duration less than approximately 500 ps, which is collimated and focused to a spot outside of the target (for example, with a waist greater than approximately 1 μm and less than approximately 100 μm. Without intending to be limited by theory, and as noted above, it is believed that the non-linear interactions that result in filament formation cause a series of acoustic compressions within the material. These acoustic compressions are understood to be substantially symmetric about the beam axis. The longitudinal length of this zone is determined by a number of pulse and beam parameters, including the position of the focus, the laser power and the pulse energy, as described above.

[0256]For example, using a 50W laser with a burst train of pulses each having a pulsewidth of approximately 10 ps, with a 2 MHz rep rate, for example, filaments ...

example 3

Filament Formation Using 1064 nm Pulsed Laser

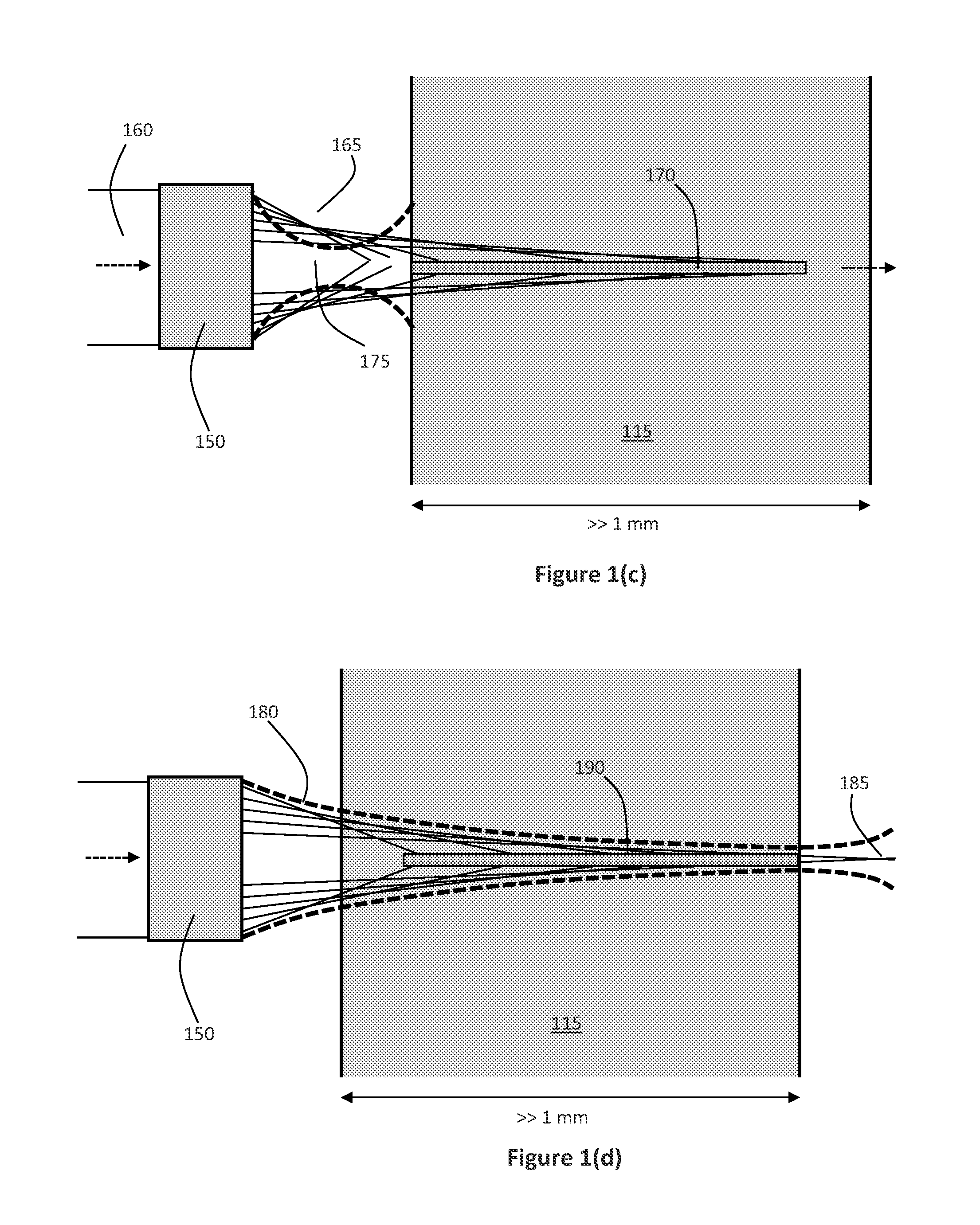

[0259]In one example implementation of the methods, apparatus and systems disclosed herein, a laser configured to output bursts of picosecond pulses as described is admitted to an optical train with a collimator and steering optics, optionally a scanner with a field corrected region capable of delivering at user selectable angles, a beam with optics designed to induce aberrated wavefronts which can be focused via negative or positive lenses such that the interaction zone exceeds the depth of the target layer to be scribed. In one example implementation, bursts of picosecond pulses emitted at 5 MHz from a 50W 1064 nm laser is focused by a series of lenses to create a 5 μm spot at focus outside the material using a doublet or triplet of lenses where the ratio, W, of focal lengths lies between −20 and +20 (L1fl / L2fl=W), depending upon the target substrate and the intended final result (full cut, scribe and break, etc.) as the length of the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com