Three-Dimensional Crystalline, Homogenous, and Hybrid Nanostructures Fabricated by Electric Field Directed Assembly of Nanoelements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

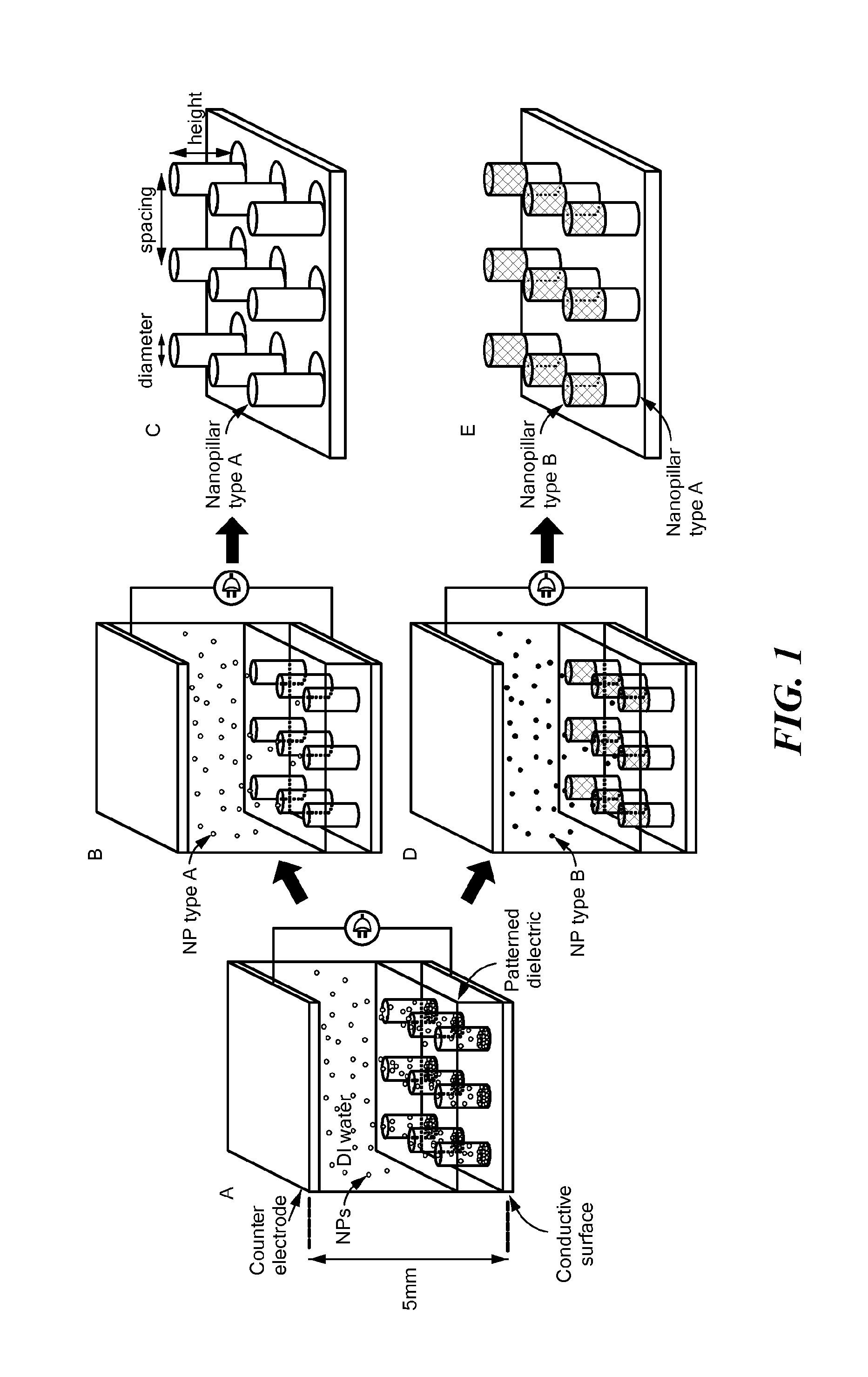

Particle and Template Preparation

[0114]Aqueous gold NPs (nominal diameter: 5 nm) were purchased from British Biocell International. Aqueous copper NP suspension (nominal diameter: 10 nm) was purchased from Meliorium Technologies (Rochester, N.Y.). Aqueous fluorescent polystyrene-latex (PSL) NP suspension (Fluoro-Max Red, nominal diameter: 22 nm) was purchased from Thermo Scientific (Waltham, Mass.). Aqueous polystyrene fluorescent silica NP suspension (fluorescent-green, nominal diameter: 30 nm) was purchased from Kisker-biotech (Steinfurt, Germany). The template depicted in FIG. 1 was prepared by sputtering Cr / Au (2 nm / 120 nm) onto a SiO2 / Si (470 nm / 380 μm) wafer followed by dicing the wafer into 12 mm×12 mm chips. The Cr / Au chips were cleaned with piranha solution (H2SO4 / H2O2, 2:1) and spin-coated with PMMA. Nanoscale patterns were fabricated using conventional electron beam lithography and developed subsequently with methyl isobutyl ketone and isopropyl alcohol (MIBK / IPA, 1:3).

example 2

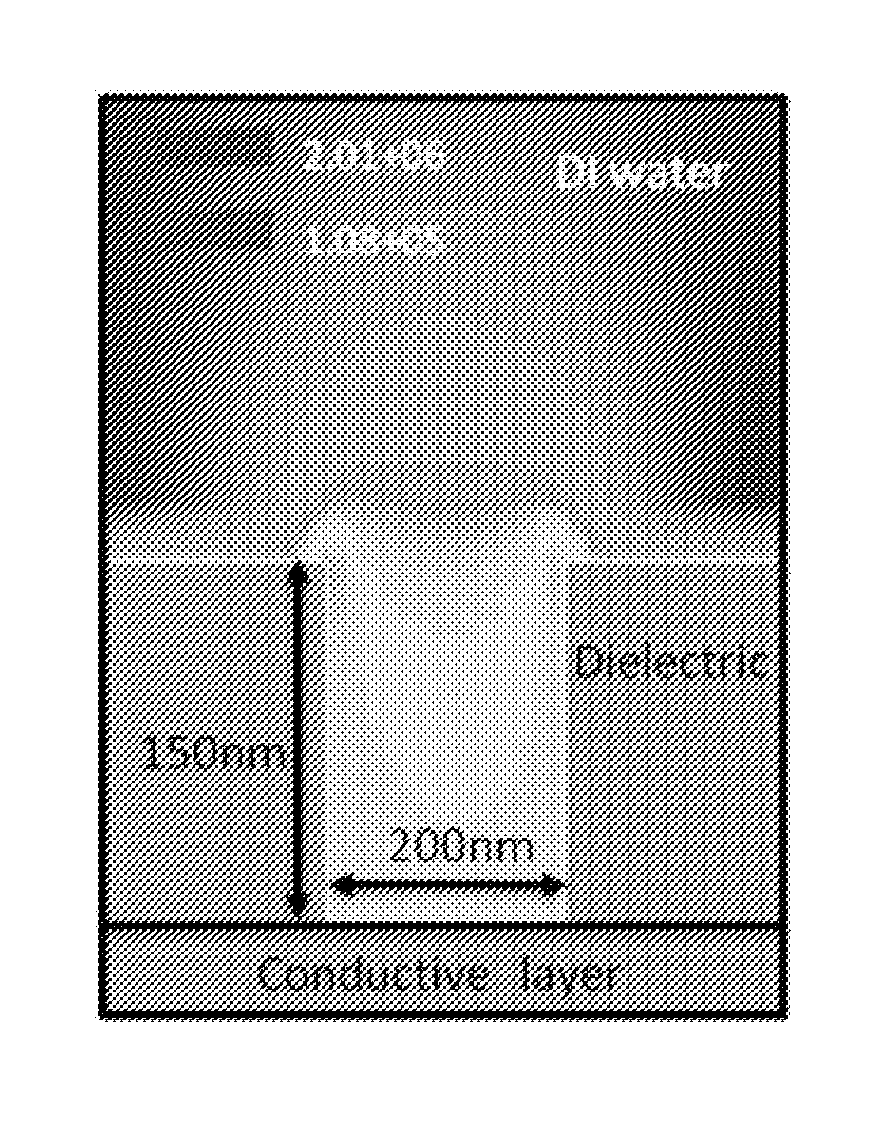

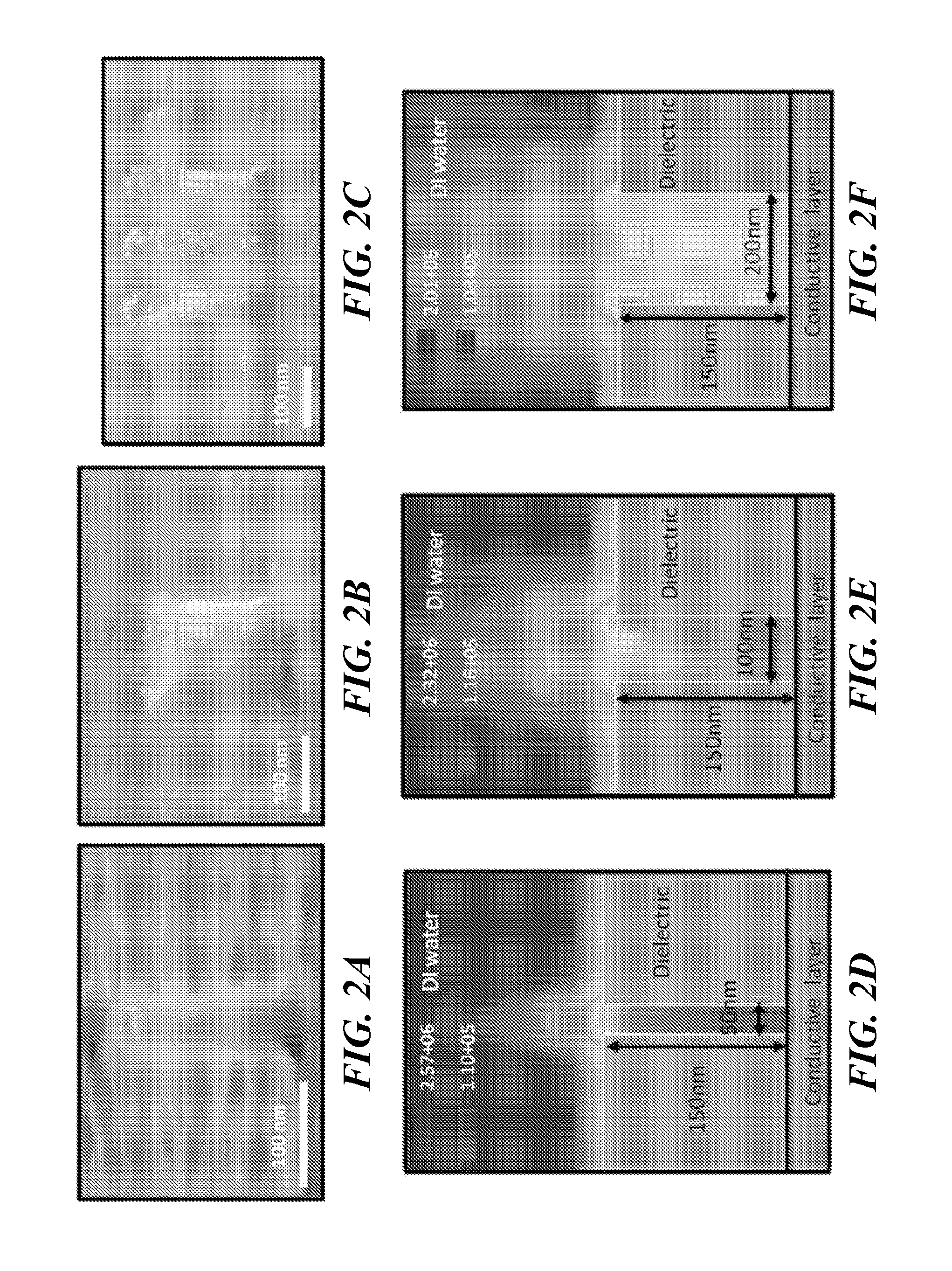

Nanoparticle-Based Nanopillar Manufacturing

[0115]The template prepared as described in Example 1 and a counter electrode (Cr / Au sputtered gold) were connected to a function / arbitrary waveform generator (Agilent 33220A) and submerged into a NP suspension. Following the application of a sinusoidal AC electric field with or without a DC offset, the template and the planar counter electrode were removed from the suspension using a dip coater (KSV NIMA) at a controlled speed (85 mm / min) Finally, the PMMA layer on the template was removed using acetone for metallic and silica nanopillars, or ethanol for PSL nanopillars.

example 3

Nanopillar Electroplating Process

[0116]Techni-Gold 25 ES RTU (ready-to-use) solution was purchased from Technic, Inc. (Pawtucket, R.I.). The solution included sulfuric acid, ethylenediamine, sodium gold sulfite and sodium sulfite. The temperature of the solution was held at 60° C. The patterned template and a counter electrode were submerged into the electroplating solution. In contrast to the directed assembly, a platinized titanium mesh was used as the counter electrode. The solution was heated at a set temperature of 60° C., while stirring with a magnetic stirrer at a set rate of 75 rpm. A DC voltage was applied between the template and the counter electrode using a Keithley 2400 source meter. The magnitude of the applied voltage and duration of deposition were altered to control the electroplating rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com