Electroplating Transitional Metal Oxides

omposition technology, applied in the field of electroplating (or electrodeposition) a transition metal oxide composition, can solve the problems of reducing the cost of the final metal oxide product, and achieve the effects of reducing the use of conductive carbon, reducing the cost of the final metal oxide product, and delivering good electrochemical performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

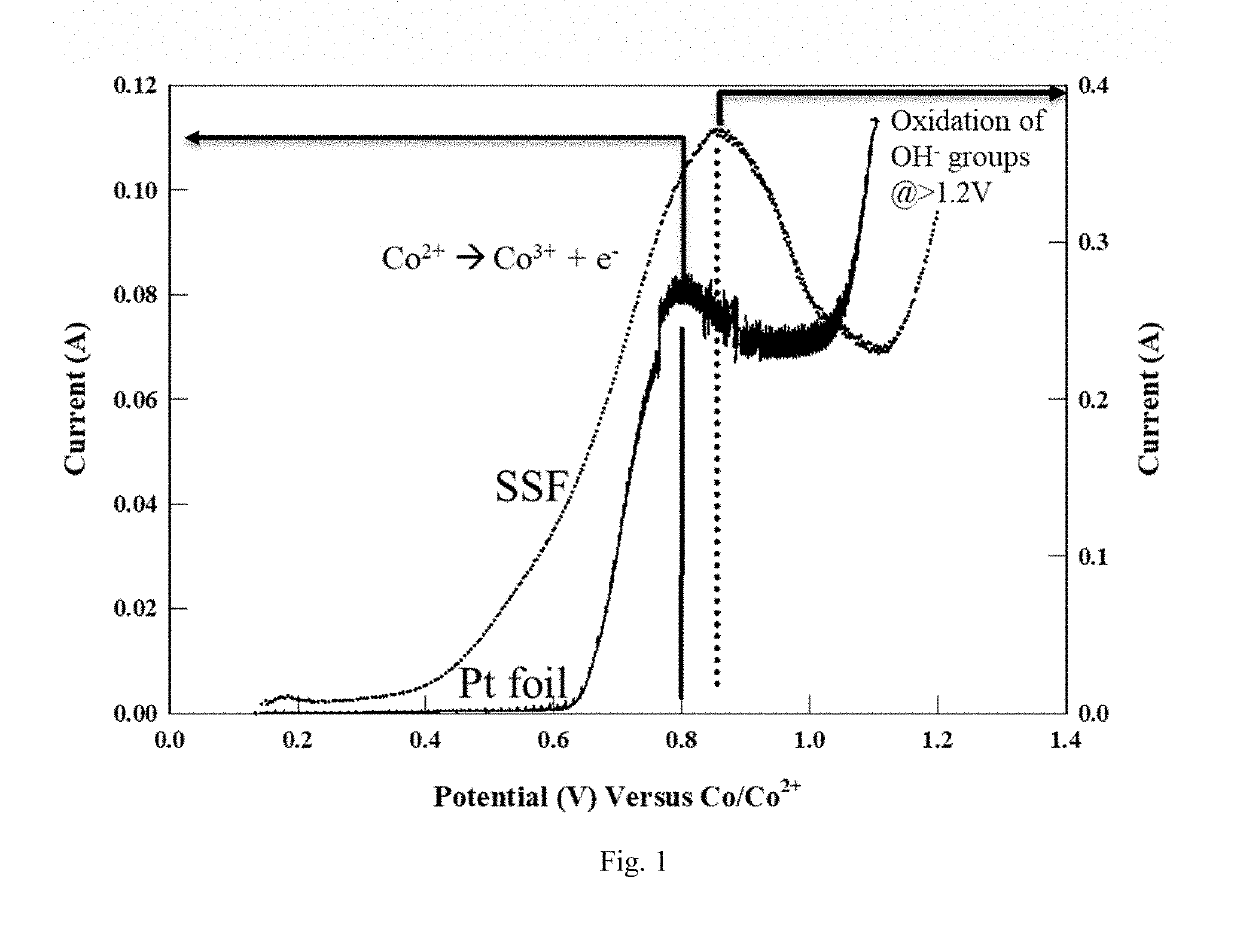

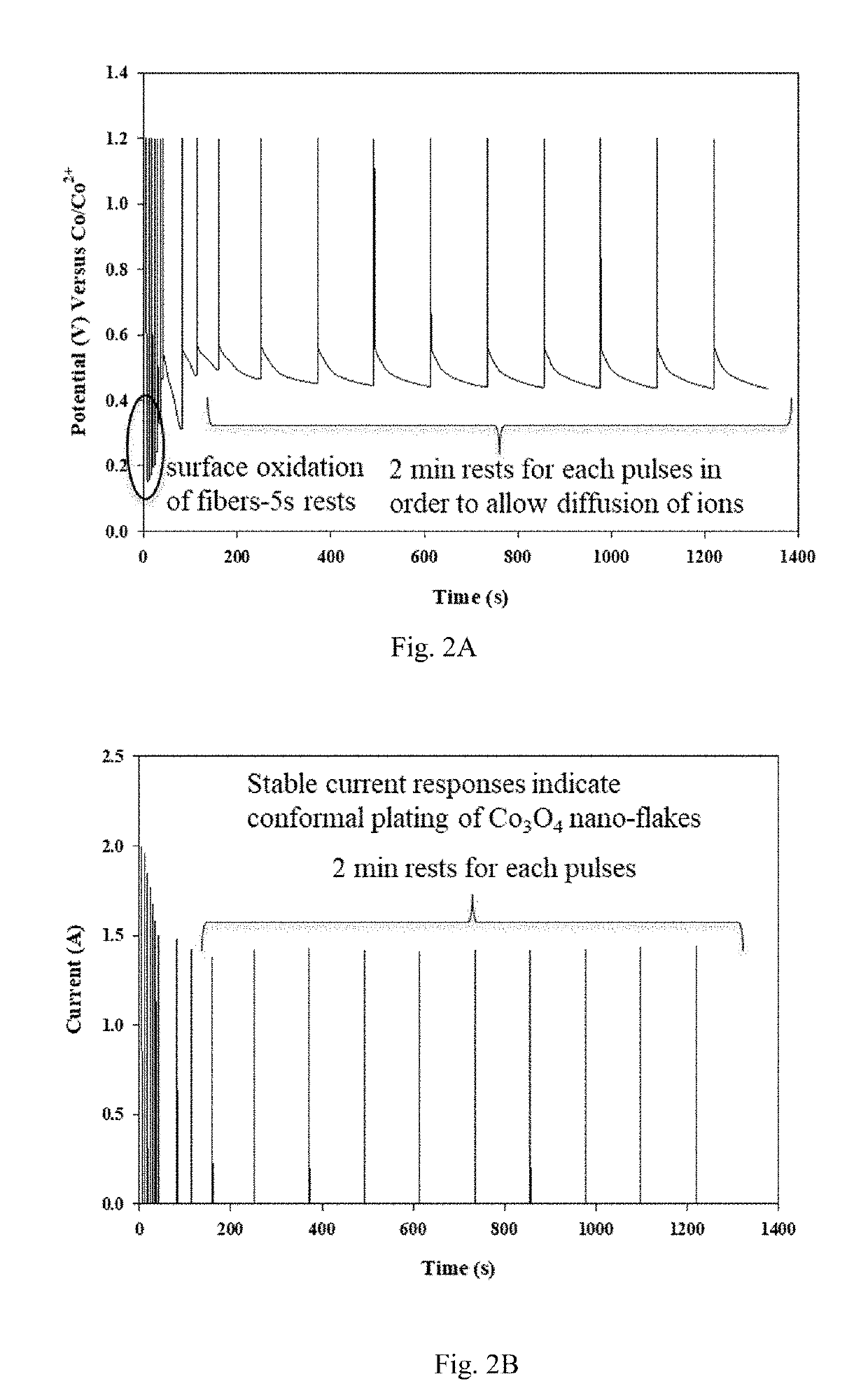

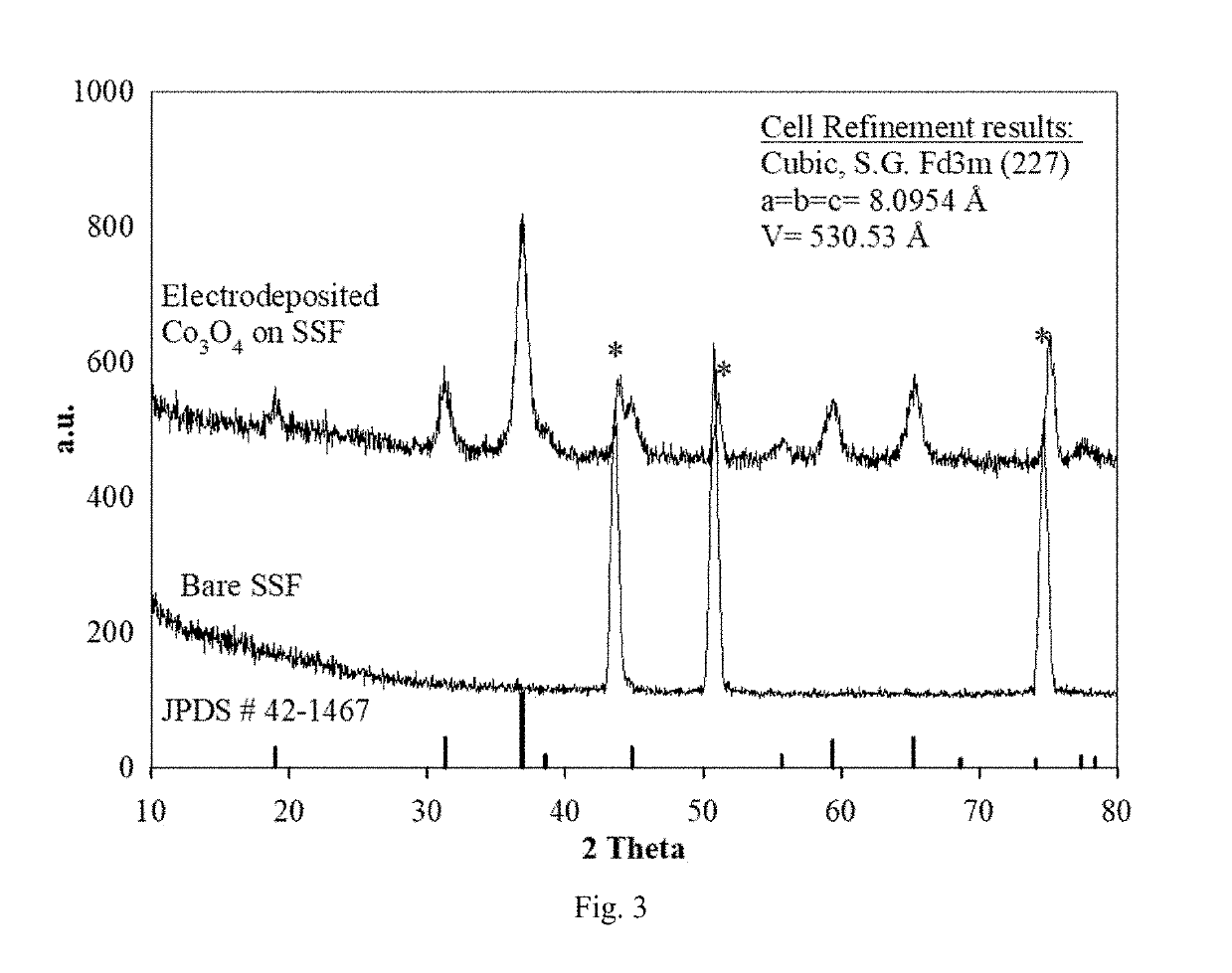

[0029]Electroplating of a transition metal oxide (TMO) was carried out using a 3-electrode system where a working electrode, a counter (Ni foil), and a pseudo reference (Co metal) electrode were immersed into a eutectic solution, which is also called a molten salt, containing a transition metal ion source.

[0030]The transition metal ion source can be aluminum, copper, chromium, cobalt, manganese, nickel, silver, gold, tin, platinum, zinc, tungsten, tantalum, rhodium, molybdenum, titanium, iron, zirconium, vanadium, hafnium, and the alloys thereof. The transition metal ion source in the plating bath can further comprise at least one of an oxide doping agent selected from the group consisting of A12O3, AlOH3, and combinations thereof

[0031]The working electrode can be an electrically conductive material selected from the group consisting of electrically conductive carbon, metal, metal alloys, metallic ceramics, oxides, polymers, and combinations thereof. Preferably, the working electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com