Joined body of piezoelectric single-crystal substrate and support substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

##ventive example 1

Inventive Example 1

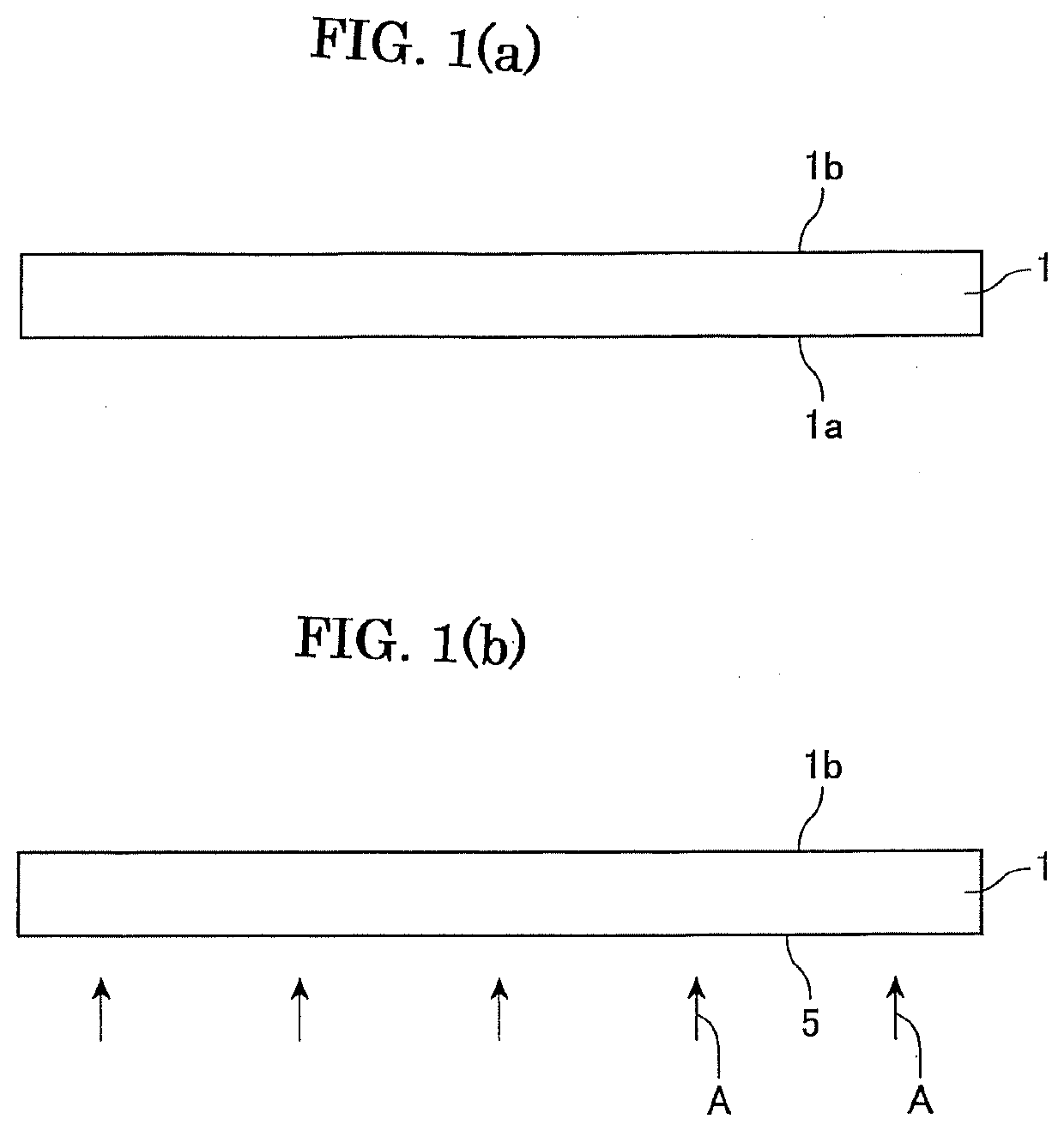

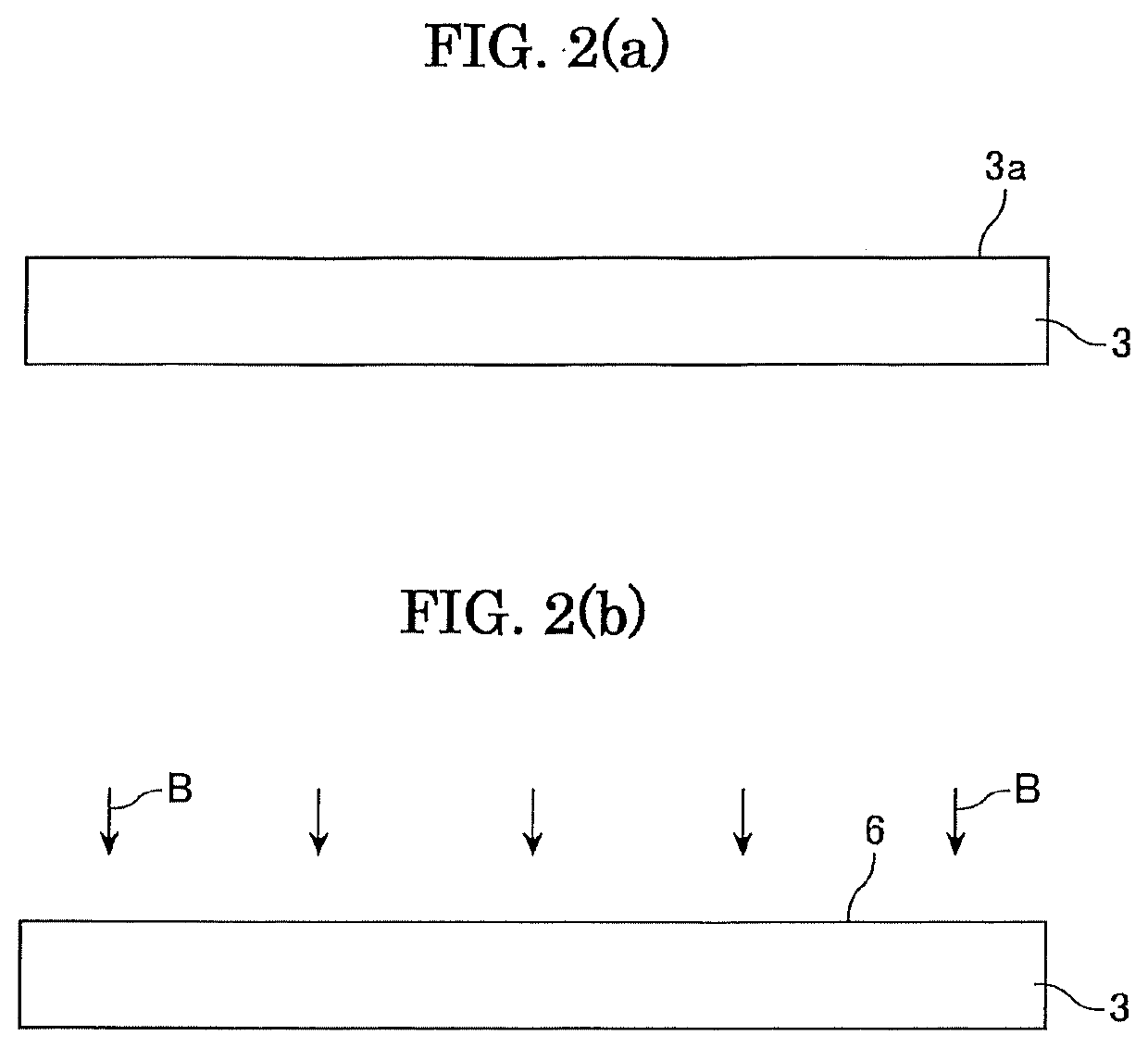

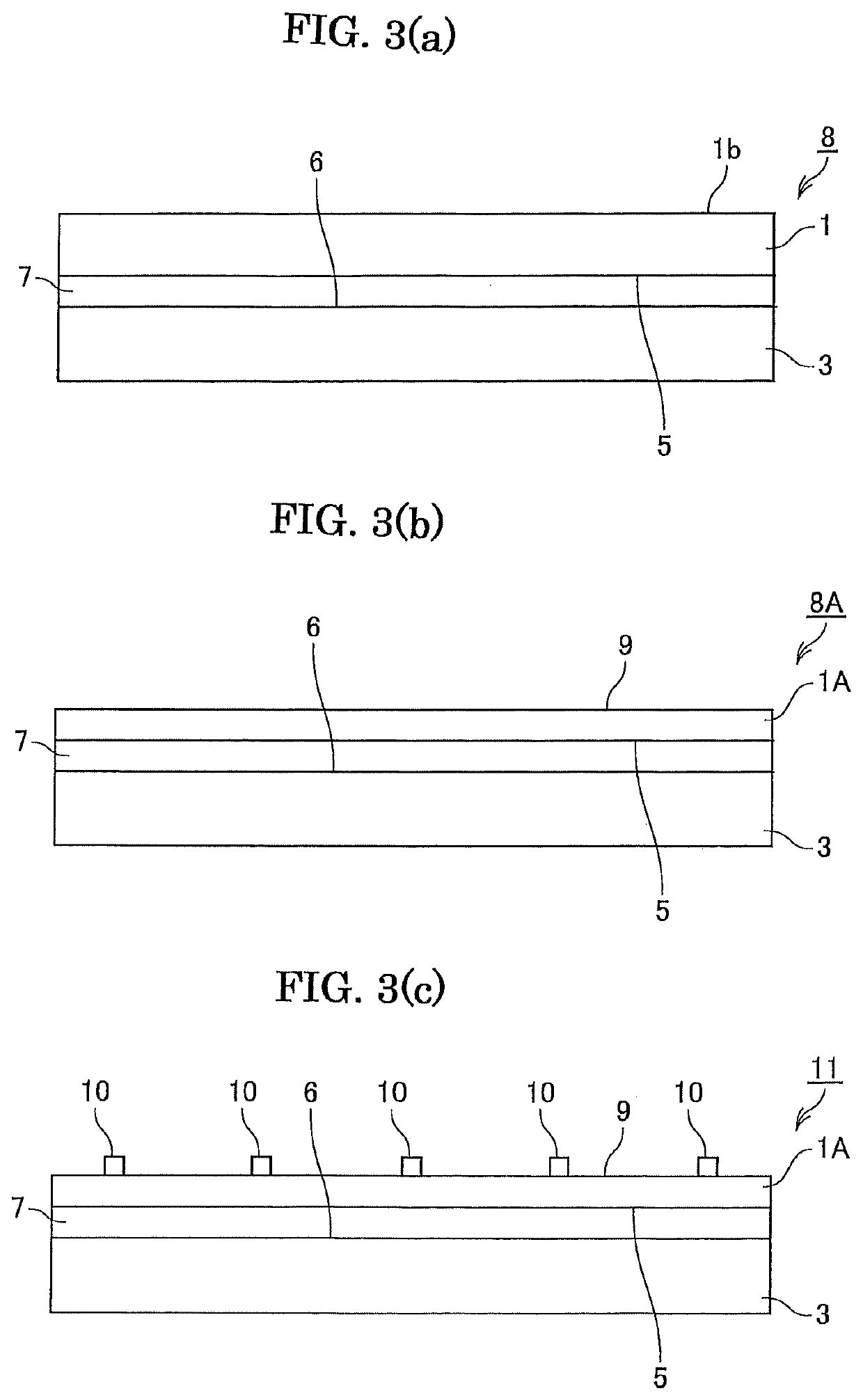

[0061]It was produced the bonded body 8A shown in FIG. 3(b), according to the method described referring to FIGS. 1 to 3.

[0062]Specifically, it was prepared a black LiTaO3 (LT) substrate (piezoelectric single crystal substrate) 1 having a thickness of 0.25 mm and of 42Y cut whose both surfaces are polished into mirror surfaces, and an Si substrate (supporting substrate) 3 having a thickness of 0.23 mm and a high resistance (≥2kΩ·cm). The sizes of the substrates were 100 mm, respectively. The surface 1a of the piezoelectric single crystal substrate 1 and surface 3a of the supporting substrate 3 were then cleaned, respectively, to remove particles from the surfaces.

[0063]The surface 1a of the piezoelectric single crystal substrate 1 and surface 3a of the supporting substrate 3 were then subjected to surface activation. Specifically, both substrates were introduced into a super-high vacuum chamber and the respective surfaces were subjected to surface activation by ar...

##ventive example 2

Inventive Example 2

[0068]The bonded body 8A was produced and evaluated according to the same procedure as that of the inventive example 1. However, according to the present example, the materials of the piezoelectric single crystal substrates 1 and 1A were made lithium niobate (LN) single crystal. The results were shown in table 1 and below.

Niobium: 45.7 atom % (Central part), 41.8 atom %

(Peripheral part)

Silicon: 33.0 atom % (Central part), 38.1 atom %

(Peripheral part)

Oxygen: 17.1 atom % (Central part), 17.4 atom %

(Peripheral part)

Argon: 4.2 atom % (Central part), 2.7 atom % (Peripheral part)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com