Patents

Literature

99results about How to "Solve Contact Corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum-silicon-zinc-rare earth-magnesium-ferrum-containing hot dip coating alloy and method for preparing same

ActiveCN101736217AUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

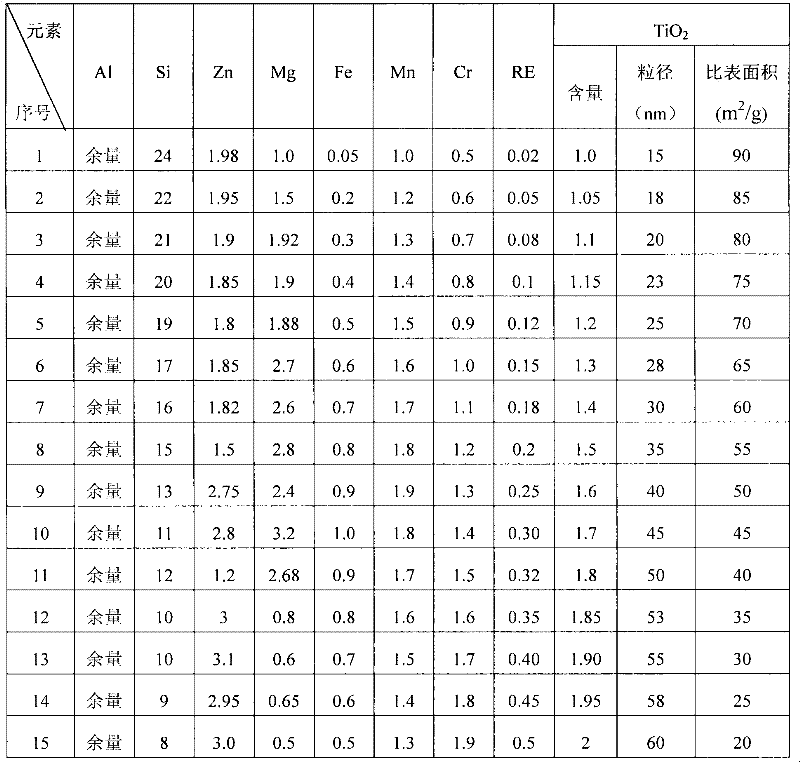

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, ferrum and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 0.05 to 1 percent of ferrum, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS

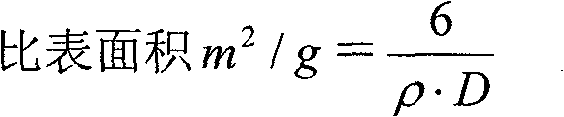

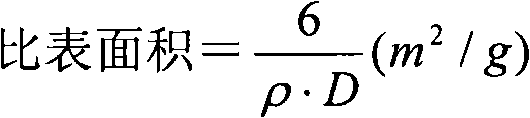

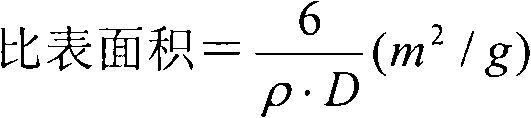

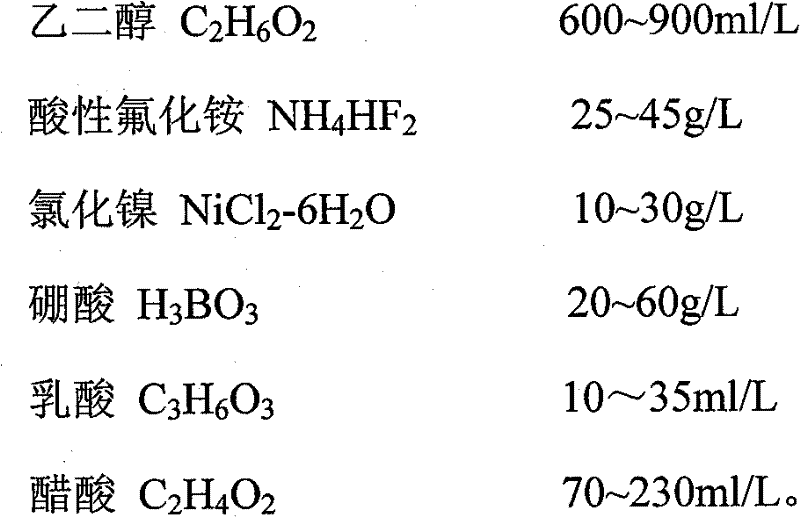

Method for carrying out surface activating treatment on surface of titanium alloy

ActiveCN101768747AShort activation timeNo corrosionHot-dipping/immersion processesVacuum evaporation coatingAcetic acidAfter treatment

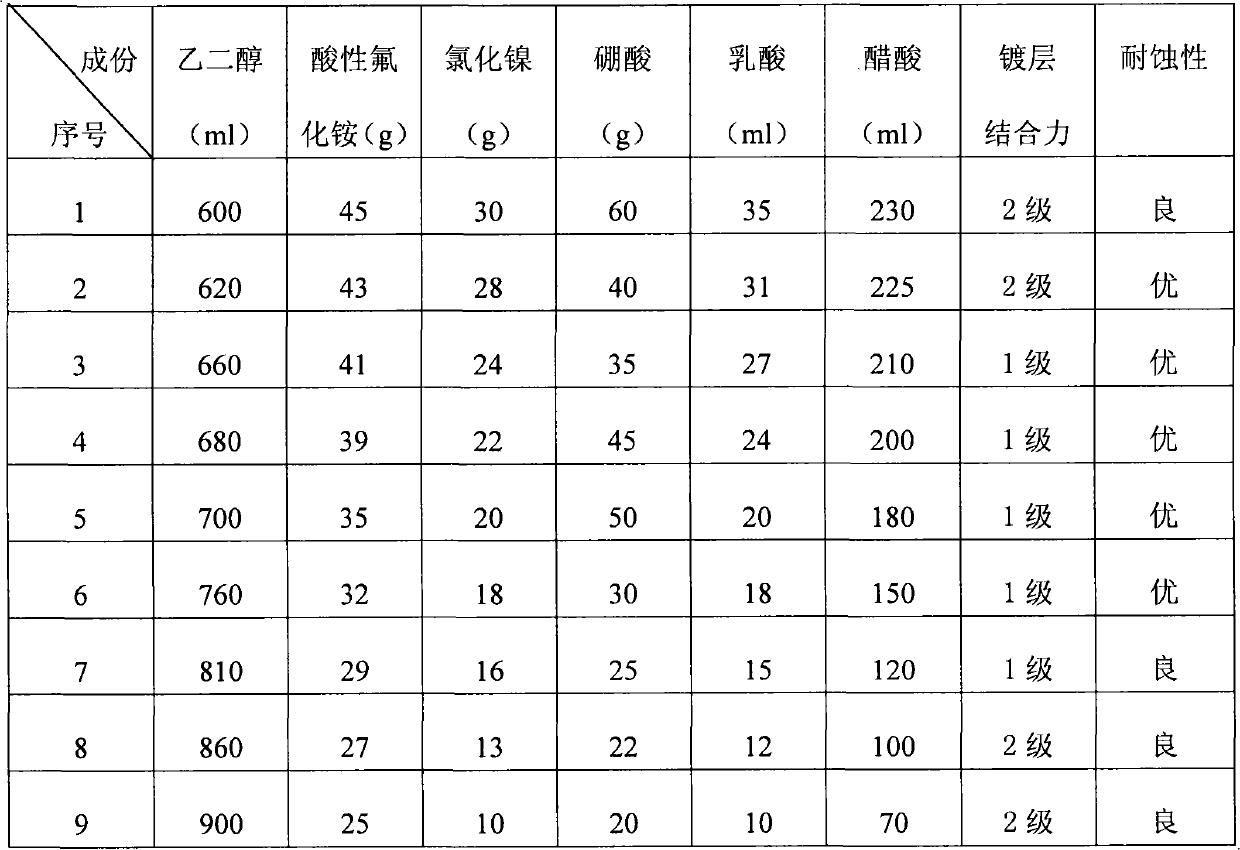

The invention relates to a method for carrying out surface activating treatment on the surface of titanium alloy. The method includes the following steps: 1. oil and rust removing is first carried out on a titanium alloy base material part; 2. etching treatment is carried out on the part; 3. surface activating treatment is carried out on the part, wherein activating solution of the surface activating treatment is a mixture of glycol, acidic ammonium fluoride, nickel chloride, boric acid, lactic acid and acetic acid, the temperature of the surface activating treatment is within 40 to 60 DEG C, and the time of the surface activating treatment is within 30 to 40min; 4. drying and after-treatment procedures are carried out. Compared with the prior art, the method has the following characteristics: the activating time is short, the activating effect is good, no corrosion is incurred on the part, the risk of corrosion on the part is basically eliminated, and the environmental pollution is mild; with high stability and quick deposition, the activating solution that the method adopts can form a coating with good corrosion / wear resisting properties and good metallurgical combination with a matrix on the surface of the titanium alloy, thereby preventing contact corrosion between the titanium alloy part and aeronautical materials such as aluminum alloy, high-temperature alloy and the like.

Owner:JIANGSU LINLONG NEW MATERIALS

Aluminum-silicon-zinc-rare earth-copper-containing hot dip coating alloy and method for preparing same

ActiveCN101736222AUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, copper and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.05 to 0.5 percent of copper, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Method for Preparing a Coating Resistant to Contact Corrosion on the Surface of Titanium Alloy

ActiveUS20110300374A1High strengthReduce mechanical property mismatchHot-dipping/immersion processesPretreated surfacesBiological activationTitanium alloy

The invention relates to a method for preparing a coating resistant to contact corrosion on the surface of titanium alloy, which comprises the following steps: 1. carrying out degreasing and derusting to a titanium alloy part; 2. carrying out etching treatment on the titanium alloy part; 3. carrying out surface activation treatment on the titanium alloy part; 4. preheating the titanium alloy part in an atmosphere protection furnace; 5. immersing the preheated titanium alloy part in plating solution; and 6. carrying out diffusion treatment on the immersion-plated titanium alloy part in a vacuum furnace whereby atoms at the interface diffuse to form a diffusion layer on a substrate and thus form a plating diffusion composite layer on the surface of the titanium alloy part. The part treated by the method completely solves the problem of contact corrosion of titanium alloy contacting with aluminum alloy and steel material.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Hot-dip coating alloy containing aluminum, silicon, zinc, rare earth and magnesium and preparation method thereof

ActiveCN101928901AUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

The invention relates to a hot-dip coating alloy which is especially used for surface coatings of titanium alloy parts. The hot-dip coating alloy comprises the following components in weight percentage: 8-24% of silicon, 1.2-3.1% of zinc, 0.02-0.5% of a rare-earth element, 0.5-3.2% of magnesium, 1-2% of a nano-oxide particle reinforcing agent, and the balance of aluminum and unavoidable impurities, wherein the nano-oxide particle reinforcing agent is chosen from one or two of TiO2 and CeO2. The hot-dip coating alloy obtained in the invention can form the coating with good corrosion resistance and good wear resistance on the surface of a titanium alloy, wherein the coating is in good metallurgical bond with a matrix.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-magnesium-copper-manganese-containing hot dip coating alloy and method for preparing same

ActiveCN101736229AUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementManganese

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, copper, manganese and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 0.05 to 0.5 percent of copper, 1.0 to 2.0 percent of manganese, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS

Aluminum-silicon-zinc-rare earth-magnesium-copper-manganese-chromium-containing hot dip coating alloy and method for preparing same

ActiveCN101736260AImprove contact corrosion resistanceImprove wear resistanceHot-dipping/immersion processesRare-earth elementManganese

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, copper, manganese, chromium, and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 0.05 to 0.5 percent of copper, 1.0 to 2.0 percent of manganese, 0.5 to 2.0 percent of chromium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS

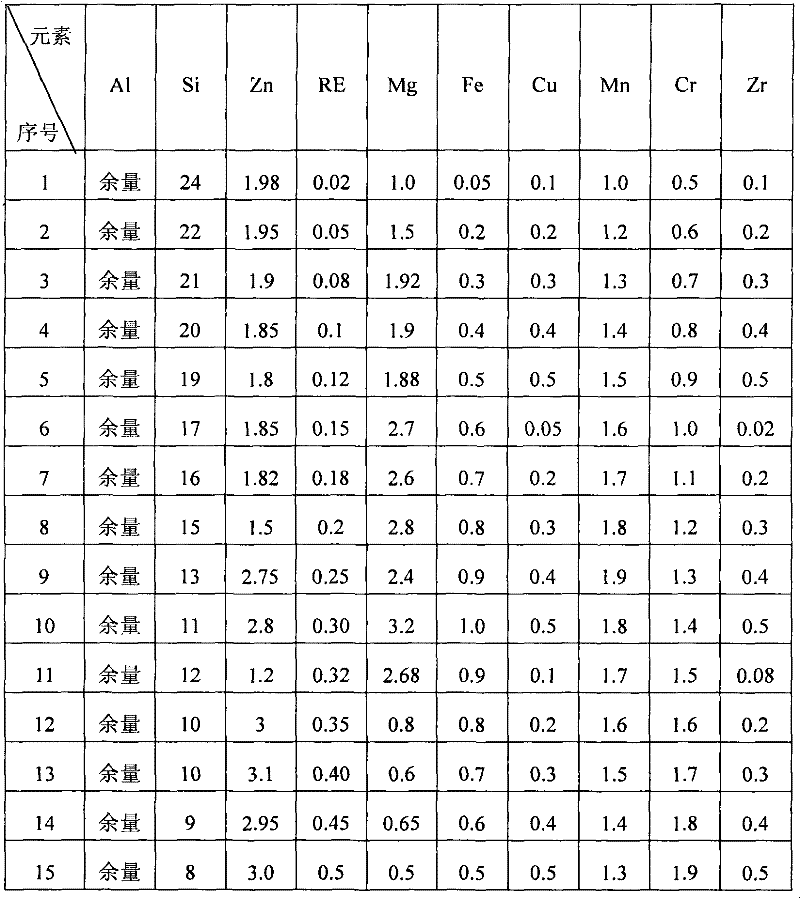

Aluminum-silicon-zinc-rare earth-magnesium-ferrum-manganese-chromium-zirconium-containing hot dip coating alloy and method for preparing same

ActiveCN101736254AImprove contact corrosion resistanceAggregation increasedHot-dipping/immersion processesEfficient propulsion technologiesRare-earth elementAluminium

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, ferrum, manganese, chromium, zirconium and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 0.05 to 1 percent of ferrum, 1.0 to 2.0 percent of manganese, 0.5 to 2.0 percent of chromium, 0.02 to 0.5 percent of zirconium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS

Aluminum-silicon-zinc-rare earth-zirconium-containing hot dip coating alloy and method for preparing same

ActiveCN101736226AUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, zirconium and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.02 to 0.5 percent of zirconium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-ferrum-copper-manganese-chromium-zirconium-containing hot dip coating alloy and method for preparing same

ActiveCN101736249AImprove contact corrosion resistanceAggregation increasedHot-dipping/immersion processesRare-earth elementCorrosion

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, ferrum, copper, manganese, chromium, zirconium and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.05 to 1 percent of ferrum, 0.05 to 0.5 percent of copper, 1.0 to 2.0 percent of manganese, 0.5 to 2.0 percent of chromium, 0.02 to 0.5 percent of zirconium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS

Aluminum-silicon-zinc-rare earth-ferrum-copper-manganese-zirconium-containing hot dip coating alloy and method for preparing same

ActiveCN101736257BUniform compositionImprove toughnessHot-dipping/immersion processesEfficient propulsion technologiesRare-earth elementManganese

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, ferrum, copper, manganese, zirconium and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc,0.02 to 0.5 percent of rare earth elements, 0.05 to 1 percent of ferrum, 0.05 to 0.5 percent of copper, 1.0 to 2.0 percent of manganese, 0.02 to 0.5 percent of zirconium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titaniumalloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-copper-manganese-chromium-zirconium-containing hot dip coating alloy and method for preparing same

ActiveCN101736255BUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementManganese

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, copper, manganese, chromium, zirconium and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.05 to 0.5 percent of copper, 1.0 to 2.0 percent of manganese, 0.5 to 2.0 percent of chromium, 0.02 to 0.5 percent of zirconium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

A method of immersion-plating titanium alloy parts

ActiveCN101760714BImprove stabilityFast depositionHot-dipping/immersion processesRare-earth elementManganese

The present invention involves a method of immersion of titanium alloy parts, including: first step: rust removal treatment of parts on the surface of the parts; second step: surface activation treatment of parts; step 3: Put parts in the protection of the atmosphere protection of the atmosphere protectionPreheating in the furnace; fourth step: immerse the preheated parts into the plating solution, and the parts are applied to the parts during the soaking process. Among them, the plating solution is mainly composed of aluminum, silicon, zinc, rare earth elements, and micro -alloy elements.The micro -alloy elements are selected from one or any of the magnesium, iron, copper, manganese, chromium, and 锆, and each composition of components accounts for the total mass of the total plating solution: silicon content: 8 to 24 %, zinc content:The contact corrosion of steel materials.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-magnesium-ferrum-chromium-zirconium-containing hot dip coating alloy and method for preparing same

ActiveCN101736267BUniform compositionImprove toughnessHot-dipping/immersion processesEfficient propulsion technologiesRare-earth elementDip-coating

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, ferrum, chromium, zirconium and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 0.05 to 1 percent of ferrum, 0.5 to 2.0 percent of chromium, 0.02 to 0.5 percent of zirconium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. Thehot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-ferrum-chromium-containing hot dip coating alloy and method for preparing same

ActiveCN101736243AImprove contact corrosion resistanceImprove wear resistanceHot-dipping/immersion processesRare-earth elementDip-coating

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, ferrum, chromium and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.05 to 1 percent of ferrum, 0.5 to 2.0 percent of chromium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS

Aluminum-silicon-zinc-rare earth-magnesium-ferrum-zirconium-containing hot dip coating alloy and method for preparing same

ActiveCN101736235BUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, ferrum, zirconium, and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 0.05 to 1 percent of ferrum, 0.02 to 0.5 percent of zirconium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-magnesium-ferrum-containing hot dip coating alloy and method for preparing same

ActiveCN101736217BUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-magnesium-copper-manganese-chromium-containing hot dip coating alloy and method for preparing same

ActiveCN101736260BUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementManganese

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, copper, manganese, chromium, and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 0.05 to 0.5 percent of copper, 1.0 to 2.0 percent of manganese, 0.5 to 2.0 percent of chromium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-magnesium-ferrum-copper-chromium-containing hot dip coating alloy and method for preparing same

ActiveCN101736264AUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, ferrum, copper, chromium and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 0.05 to 1 percent of ferrum, 0.05 to 0.5 percent of copper, 0.5 to 2.0 percent of chromium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Anti-contact corrosion tial-based alloy coating and preparation method thereof

ActiveCN106086579BImprove plasticitySolve Contact CorrosionMolten spray coatingElectrode potentialAlloy coating

The invention discloses a TiAl-based alloy coating resistant to contact corrosion and a preparation method of the TiAl-based alloy coating. The coating is composed of the following elements including, by atom percentage, 44-47at% of Al, 2-4at% of Nb, 4-10at% of V, 0-2.5at% of Cr, 0-0.5at% of B and the balance Ti. According to the coating, intermediate alloy AlNb, AlV and AlCr, TiB2, Al particles and high-purity sponge Ti are mixed and then are prepared into spraying powder; and then the spraying powder is sprayed onto the surface of an aluminum alloy base through a low-temperature supersonic spraying technology. The bonding strength of the coating can reach 30 MPa or above, after the coating is prepared on the surface of an aluminum alloy, the electrode potential of the surface of the aluminum alloy can be improved, the self-corrosion current can be reduced, the contact corrosion sensitivity between the aluminum alloy and a titanium alloy can be reduced, and therefore the aluminum alloy can make direct contact with the titanium alloy for use, and the contact corrosion preventing requirement of aluminum alloy / titanium alloy dissimilar metal is met.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Aluminum-silicon-zinc-rare earth-manganese-chromium-containing hot dip coating alloy and method for preparing same

ActiveCN101736245BUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementManganese

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, manganese, chromium and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 1.0 to 2.0 percent of manganese, 0.5 to 2.0 percent of chromium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitableimpurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-magnesium-ferrum-copper-chromium-zirconium-containing hot dip coating alloy and method for preparing same

ActiveCN101736253BUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, ferrum, copper, chromium, zirconium and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 0.05 to 1 percent of ferrum, 0.05 to 0.5 percent of copper, 0.5 to 2.0 percent of chromium, 0.02 to 0.5 percent of zirconium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-ferrum-containing hot dip coating alloy and method for preparing same

ActiveCN101736223AUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, ferrum and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.05 to 1 percent of ferrum, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS

Aluminum-silicon-zinc-rare earth-magnesium-copper-zirconium-containing hot dip coating alloy and method for preparing same

ActiveCN101736231BUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, copper, zirconium and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 0.05 to 0.5 percent of copper, 0.02 to 0.5 percent of zirconium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-magnesium-manganese-chromium-zirconium-containing hot dip coating alloy and method for preparing same

ActiveCN101736268BUniform compositionImprove toughnessHot-dipping/immersion processesEfficient propulsion technologiesRare-earth elementManganese

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, manganese, chromium, zirconium and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 1.0 to 2.0 percent of manganese, 0.5 to 2.0 percent of chromium, 0.02 percent to 0.5 percent of zirconium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-magnesium-ferrum-copper-manganese-containing hot dip coating alloy and method for preparing same

ActiveCN101736263BUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementManganese

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, ferrum, copper, manganese and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc,0.02 to 0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 0.05 to 1 percent of ferrum, 0.05 to 0.5 percent of copper,1.0 to 2.0 percent of manganese, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-ferrum-copper-manganese-containing hot dip coating alloy and method for preparing same

ActiveCN101736272AUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementManganese

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, ferrum, copper, manganese and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.05 to 1 percent of ferrum, 0.05 to 0.5 percent of copper, 1.0 to 2.0 percent of manganese, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-copper-zirconium-containing hot dip coating alloy and method for preparing same

ActiveCN101736240BUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementDip-coating

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-silicon-zinc-rare earth-magnesium-ferrum-manganese-chromium-zirconium-containing hot dip coating alloy and method for preparing same

ActiveCN101736254BUniform compositionImprove toughnessHot-dipping/immersion processesEfficient propulsion technologiesRare-earth elementManganese

The invention relates to hot dip coating alloy specially used for surface coatings of titanium alloy parts. The hot dip coating alloy consists of aluminum, silicon, zinc, rare earth elements, magnesium, ferrum, manganese, chromium, zirconium and reinforcing agent of particles of nano oxides, and based on the total weight of the alloy, the alloy comprises 8 to 24 percent of silicon, 1.2 to 3.1 percent of zinc, 0.02 to 0.5 percent of rare earth elements, 0.5 to 3.2 percent of magnesium, 0.05 to 1 percent of ferrum, 1.0 to 2.0 percent of manganese, 0.5 to 2.0 percent of chromium, 0.02 to 0.5 percent of zirconium, 1 to 2 percent of reinforcing agent of particles of nano oxides, and the balance of aluminum and inevitable impurities, wherein the reinforcing agent of the particles of the nano oxides may be one or two of TiO2 and CeO2. The hot dip coating alloy produced by the method can form a coating with good corrosion resistance and wearing resistance and good metallurgical bonding property with a matrix on the surface of the titanium alloy.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Hot-dipping alloy containing aluminum, silicon, zinc, rare earth, magnesium, ferrum, manganese and chromium and preparation method thereof

ActiveCN101928903BUniform compositionImprove toughnessHot-dipping/immersion processesRare-earth elementManganese

The invention relates to a hot-dipping alloy specially used for coating layers of titanium alloy part surfaces, wherein the hot-dipping alloy consists of 8-24 percent of silicon, 1.2-3.1 percent of zinc, 0.02-0.5 percent rare earth elements, 0.5-3.2 percent of manganese content, 0.05-1 percent of ferrum, 1.0-2.0 percent of magnesium, 0.5-2.0 percent of chromium, 1-2 percent of nanometer oxide particle reinforcing agent, and the balance of aluminum and inevitable impurities, wherein the nanometer oxide particle reinforcing agent is TiO2 and / or CeO2. The coating layers which have high corrosion-resistance and abrasion-resistance and can be bonded with matrix metallurgy can be formed on the titanium alloy surfaces.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com