Method for carrying out surface activating treatment on surface of titanium alloy

A surface activation treatment, titanium alloy technology, applied in liquid chemical plating, gaseous chemical plating, metal material coating process, etc., can solve the problem of affecting the corrosion resistance of the final coating, unsuitable for manufacturing status, poor coating adhesion, etc. problems, to achieve the effect of eliminating the risk of corrosion, low production cost, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047](1) After degreasing the parts, carry out rust removal treatment by liquid sandblasting, the abrasive particle size is 0.10mm, and the sandblasting time is 20 minutes. After blasting, a fine polish is achieved by mechanical grinding followed by ultrasonic cleaning in acetone solution followed by a deionized water rinse.

[0048] (2) Etch the parts after degreasing and derusting in the mixed solution of hydrochloric acid HCl 94% (volume fraction) + hydrofluoric acid HF 6% (volume fraction) at room temperature for 1 minute, and then rinse with deionized water.

[0049] (3) Activation treatment in a mixed solution of ethylene glycol, acidic ammonium fluoride, nickel chloride, boric acid, lactic acid, and acetic acid at a temperature of 40°C for 40 minutes, rinse with deionized water, and dry.

[0050] (4) Hot-dip coating.

Embodiment 2

[0052] (1) After degreasing the parts, carry out rust removal treatment by liquid sandblasting, the abrasive particle size is 0.12mm, and the sandblasting time is 15 minutes. After blasting, a fine polish is achieved by mechanical grinding followed by ultrasonic cleaning in acetone solution followed by a deionized water rinse.

[0053] (2) Etch the parts after degreasing and derusting in the mixed solution of hydrochloric acid HCl 95% (volume fraction) + hydrofluoric acid HF5% (volume fraction) at room temperature for 2 minutes, and then rinse with deionized water.

[0054] (3) Activation treatment in a mixed solution of ethylene glycol, acidic ammonium fluoride, nickel chloride, boric acid, lactic acid, and acetic acid at a temperature of 50°C for 35 minutes, rinse with deionized water, and dry.

[0055] (4) thermal spray coating.

Embodiment 3

[0057] (1) After degreasing the parts, carry out rust removal treatment by liquid sandblasting, the abrasive particle size is 0.15mm, and the sandblasting time is 10 minutes. After blasting, a fine polish is achieved by mechanical grinding followed by ultrasonic cleaning in acetone solution followed by a deionized water rinse.

[0058] (2) The parts after degreasing and derusting are etched in the mixed solution of hydrochloric acid HCl 96% (volume fraction) + hydrofluoric acid HF4% (volume fraction) at room temperature for 3 minutes, and then rinsed with deionized water.

[0059] (3) Thermal spraying, temperature 60°C, time 30min, rinse with deionized water, and dry.

[0060] (4) Electroplating coating.

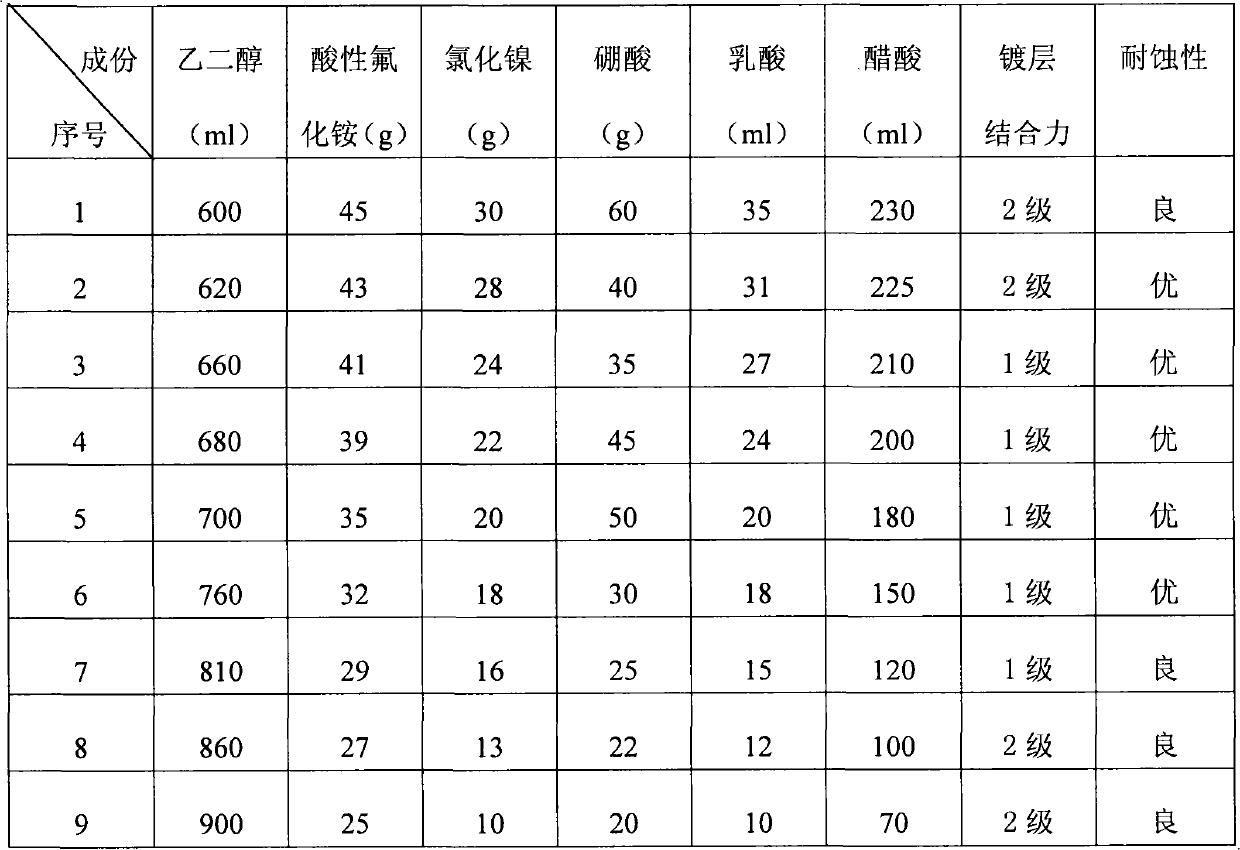

[0061] Wherein, the composition and content of the activating solution of surface activation treatment in embodiment 1-3 are as shown in Table 1 below, and it should be noted that some preferred implementations of the composition and content of the activating solution of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com