Method for producing poisonless rape seed concentrate protein from coat removed cold pressed cake of rapeseed

A rapeseed protein concentrate, rapeseed technology, which is applied to the protein composition of vegetable seeds, the preparation method of peptides, chemical instruments and methods, etc. The process is complex and other problems, to achieve the effect of good detoxification effect, no three waste pollution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

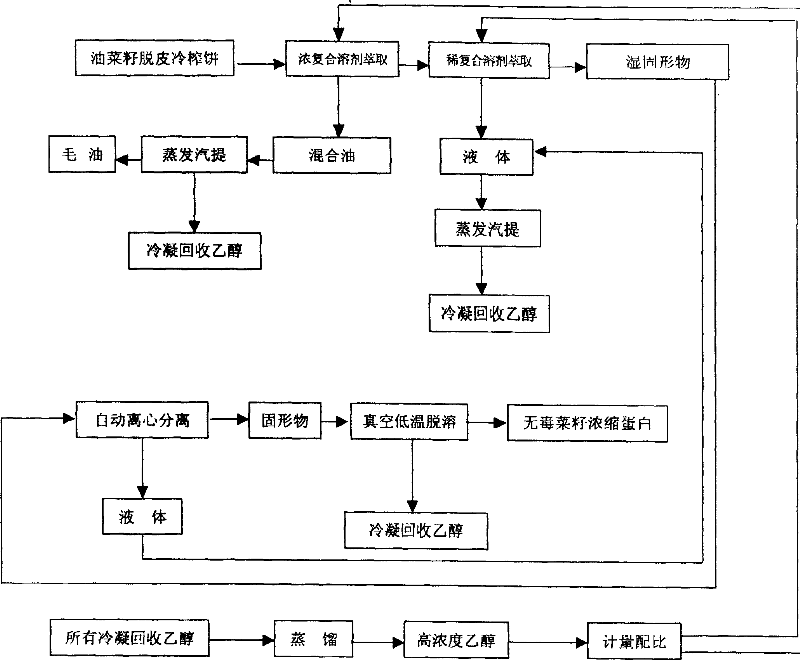

[0012] Further describe the present invention below in conjunction with accompanying drawing embodiment

[0013] Accompanying drawing is the embodiment of the present invention, attached table is the dehulled cold-pressed rapeseed cake of the embodiment of the present invention and the component content of prepared rapeseed protein concentrate.

[0014] Referring to accompanying drawing, rapeseed dehulled cold-pressed cake enters leaching tank and carries out first-stage complex solvent extraction, and complex solvent is 90% (v / v) hydrous ethanol and adds the hydrogen that accounts for 0.1% (w / v) of hydrous ethanol content Sodium oxide, the extraction temperature is 76°C, the solid-liquid ratio is 1:10, the number of extractions is 5 times, and each extraction time is about 45 minutes. The mixed oil obtained after extraction is evaporated and stripped to recover ethanol and obtain extracted crude oil. The solids after the extraction are carried out with the second-stage compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com