YAG chip-type white-light light-emitting-diode and its packing method

A light-emitting diode and chip-type technology, applied in the field of white light LED, can solve the problems of poor uniformity of white light, and achieve the effects of stable high-temperature performance, simple wafer post-processing technology, and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Growth of single crystal phosphor cerium yttrium aluminum garnet:

[0026] According to the chemical composition expression Y 2.97 Al 5 o 12 : 0.03Ce (x=0, y=0, m=0.01, n=0) weighing

[0027] Y 2 o 3 : 335.34g

[0028] Al 2 o 3 : 254.9g

[0029] CeO 2 : 5.16g

[0030] Grinding and mixing evenly, and then roasting under a hydrogen atmosphere; then placing the roasted product in an Ir iridium crucible of an intermediate frequency furnace, and growing a single crystal phosphor cerium yttrium aluminum garnet by pulling method under an Ar atmosphere.

[0031] (2) Post-treatment of the single crystal phosphor cerium yttrium aluminum garnet: cutting the single crystal phosphor cerium yttrium aluminum garnet obtained above to obtain a circular single wafer with a thickness of 0.1 mm, and then the single wafer Perform single-side polishing treatment to finally obtain the desired sheet-type single crystal phosphor cerium yttrium aluminum garnet.

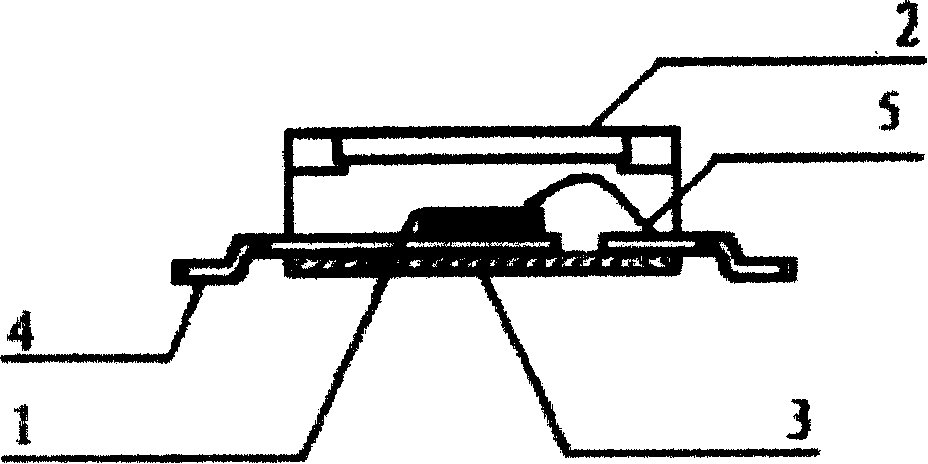

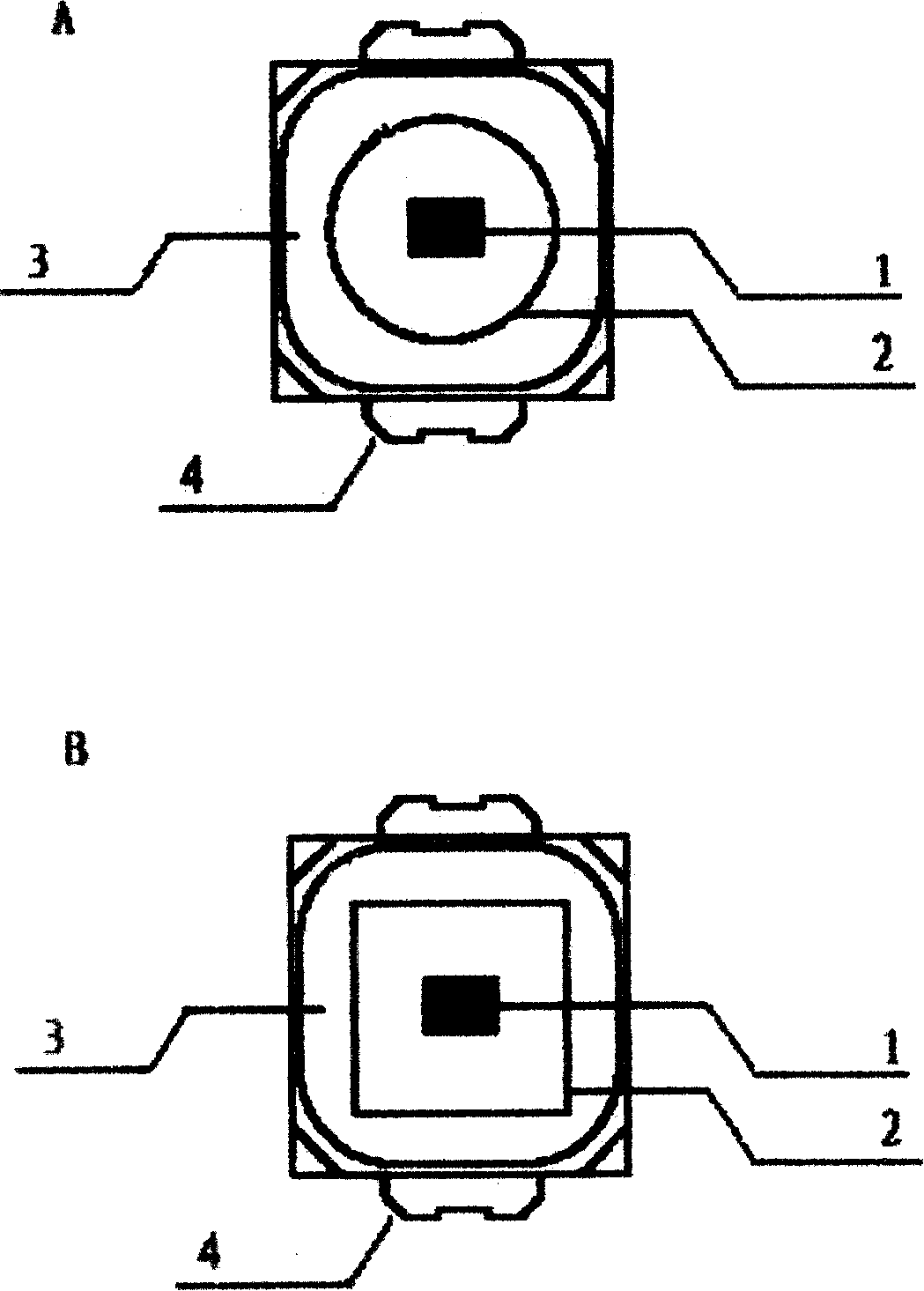

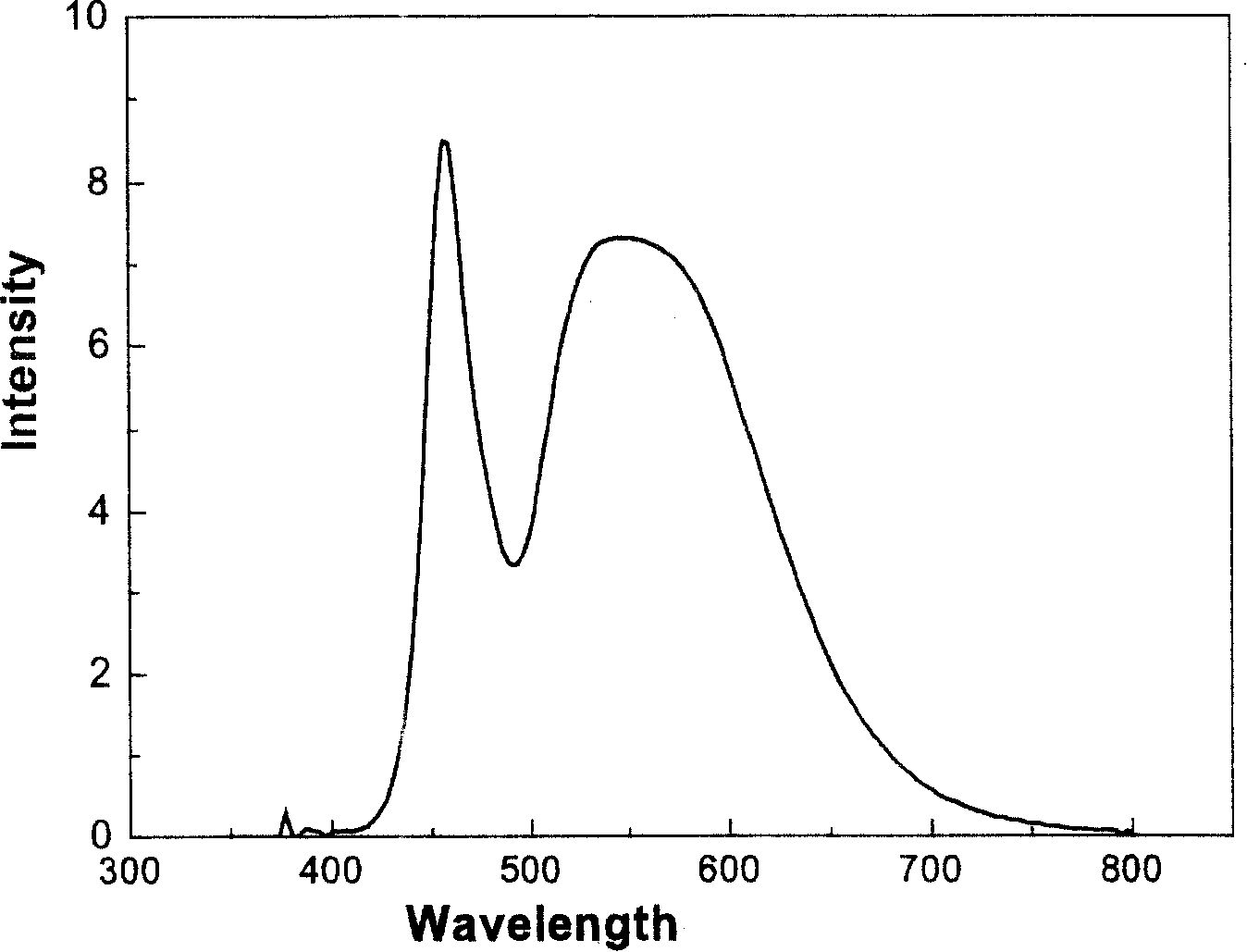

[0032] (3) Packagi...

Embodiment 2

[0034] (1) Growth of single crystal phosphor cerium yttrium aluminum garnet:

[0035] According to the chemical composition expression (Y 0.3 Gd 0.5 ) 3 (Ga 0.5 Al 0.5 ) 5 o 12 : 0.3Ce, 0.3Pr (x=0.5, y=0.5, m=0.1, n=0.1) weighed

[0036] Y 2 o 3 : 101.62g Gd 2 o 3 : 271.95g

[0037] Al 2 o 3 : 127.45g Ga 2 o 3 : 234.3g

[0038] CeO 2 : 51.63g Pr 6 o 11 : 51.07g

[0039] Grinding and mixing evenly, and then roasting under a hydrogen atmosphere; then placing the roasted product in an Ir iridium crucible of an intermediate frequency furnace, and growing a single crystal phosphor cerium yttrium aluminum garnet by pulling method under an Ar atmosphere.

[0040] (2) Post-processing of the single crystal phosphor cerium yttrium aluminum garnet: cutting the single crystal phosphor cerium yttrium aluminum garnet obtained above to obtain a square single wafer with a thickness of 1.0 mm, and then performing Double-sided polishing treatment finally obtains the desired...

Embodiment 3

[0043] (1) Growth of single crystal phosphor cerium yttrium aluminum garnet:

[0044] According to the chemical composition expression (Y 0.71 Gd 0.2 ) 3 (Ga 0.3 Al 0.7 ) 5 o 12 : 0.15Ce, 0.12Sm (x=0.2, y=0.3, m=0.05, n=0.04) weighing

[0045] Y 2 o 3 : 240.5g Gd 2 o 3 : 108.78g

[0046] Al 2 o 3 : 178.43g Ga 2 o 3 : 140.58g

[0047] CeO 2 : 25.82g Sm 2 o 3 : 20.93g

[0048] Grinding and mixing evenly, and then roasting under a hydrogen atmosphere; then placing the roasted product in an Ir iridium crucible in an intermediate frequency furnace, and growing it by a pulling method under an Ar atmosphere to obtain a single crystal phosphor cerium yttrium aluminum garnet;

[0049] (2) Post-treatment of the single crystal phosphor cerium yttrium aluminum garnet: cutting the single crystal phosphor cerium yttrium aluminum garnet obtained above to obtain a single wafer with a thickness of 0.55mm, and then double-cutting the single wafer. The surface is not polishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com