Preparation process of nanometer hollow IIB sulfide ball

A technology of nanomaterials and sulfides, applied in nanostructure manufacturing, chemical instruments and methods, zinc sulfide, etc., can solve the problems of difficult product washing, troublesome preparation process, complicated operation, etc., and achieve easy-to-obtain raw materials, low production costs, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take the fresh egg inner membrane, wash it with distilled water, dry it, place it in the mixed solution of chloroform / o-phenanthroline and soak it for 30 hours, and make the supporting liquid film; wherein every 40 milliliters of o-phenanthroline is added with 0.1 gram of chloroform;

[0027] (2) Prepare ZnCl with a molar concentration of 0.20mol / L respectively 2 solution and Na 2 S solution, in which Na 2 Add 1% (volume percentage) citric acid to the S solution. Then solution A and solution B are respectively placed on the left and right sides of the supporting liquid film obtained in step (1), i.e. the egg film, left to stand for reaction for 2 days, take out the solution containing precipitation on one side, and carry out centrifugation to obtain The precipitated product was successively washed three times with distilled water, acetone and absolute ethanol to obtain the desired product ZnS.

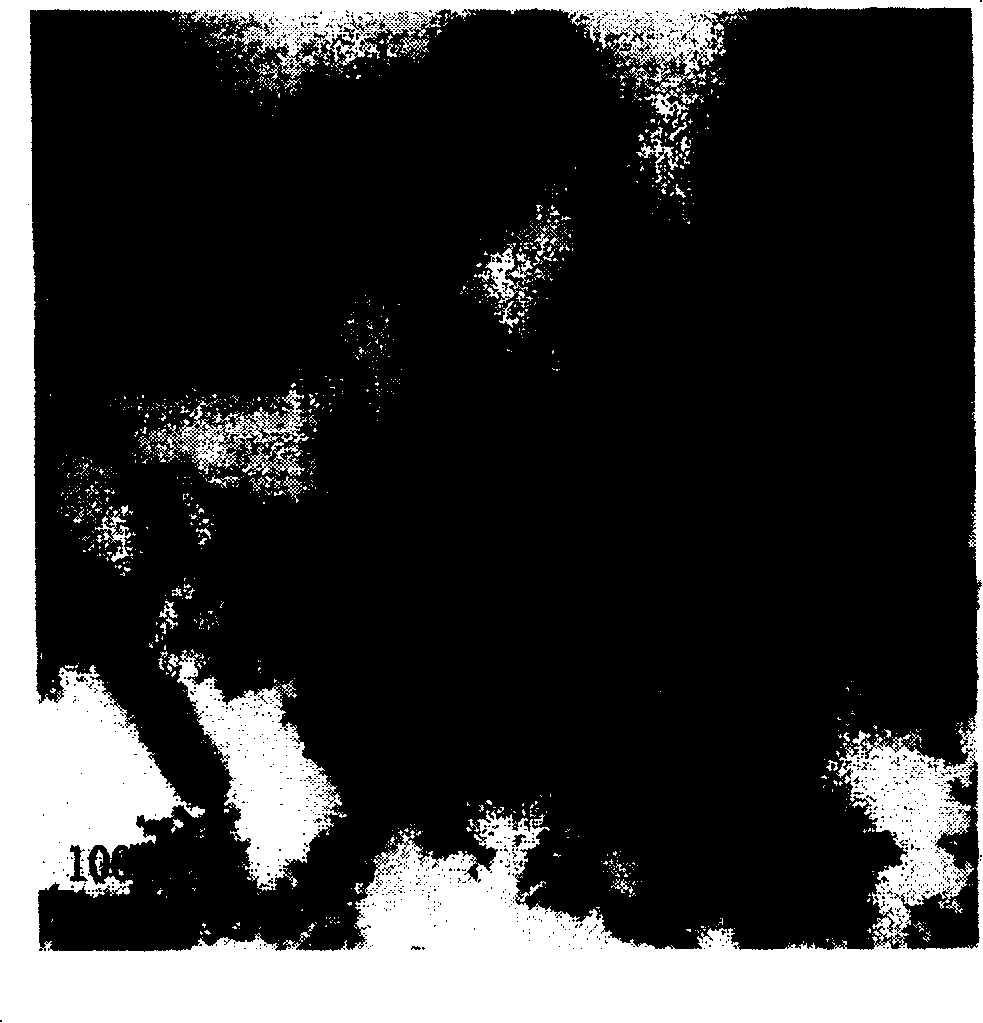

[0028] The resulting product was stored in absolute ethanol, and th...

Embodiment 2

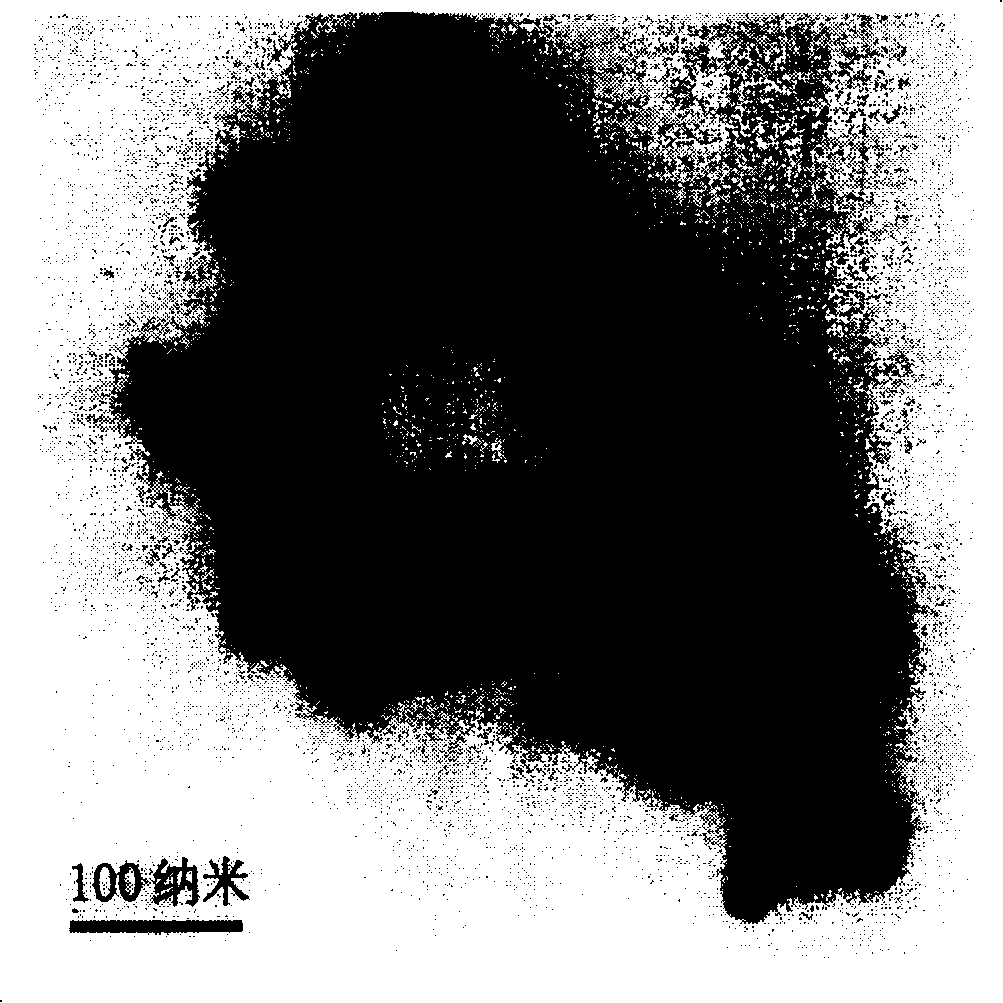

[0030] Prepare molar solution of 0.20mol / L CdSO 4 and Na 2 S solution, in which Na 2 Add 1% (volume percentage) citric acid to the S solution. Other conditions and steps are exactly the same as in Example 1. The resulting product CdS was stored in absolute ethanol, and the structure and morphology of the product were characterized by XRD and TEM, respectively. figure 2 It can be seen that the obtained product is a hollow sphere with a diameter of 30-50 nanometers, and the crystal system of the product is the same as that of Example 1. The product has high purity. Compared with Example 1, the blue shift of the fluorescence peak is larger.

Embodiment 3

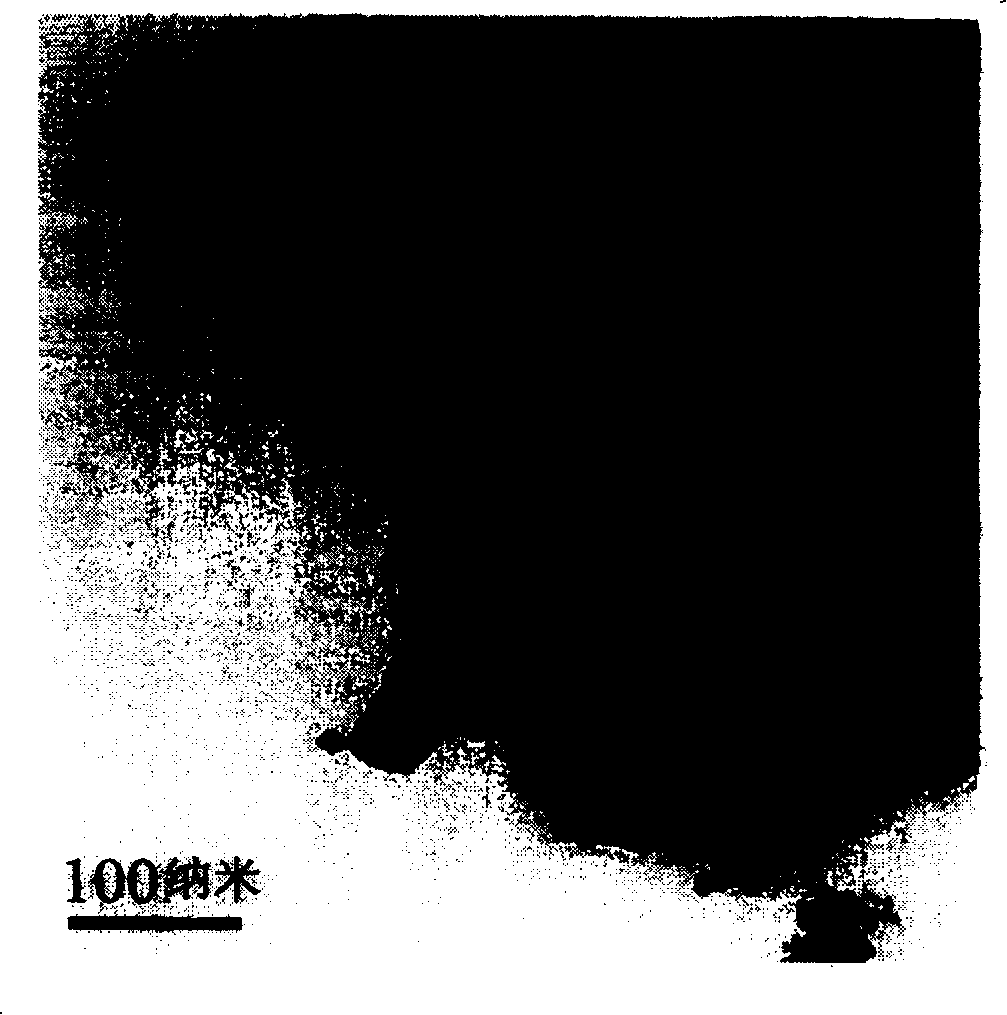

[0032] Prepare HgCl with a molar concentration of 0.15mol / L respectively 2 solution and Na 2 S solution, in which Na 2 Add 1% (volume percentage) citric acid to the S solution. Other conditions and steps are exactly the same as in Example 1, and the obtained product HgS is stored in absolute ethanol. The structure and morphology of the product were characterized by XRD and TEM, respectively. image 3 It can be seen that the obtained product is a hollow sphere with a diameter of about 150 nanometers, and the crystal system of the product is the same as in Example 1. The product has high purity. Compared with Example 1, the blue shift of the fluorescence peak is larger.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com