Laminated filter based on MEMS technology

A filter and stacked technology, which is applied in the coupling of waveguide devices, resonators, and optical waveguides, can solve the problems of attenuation performance that cannot meet the requirements of use and large volume, and achieve shortened design cycles, small volume, and reduced costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

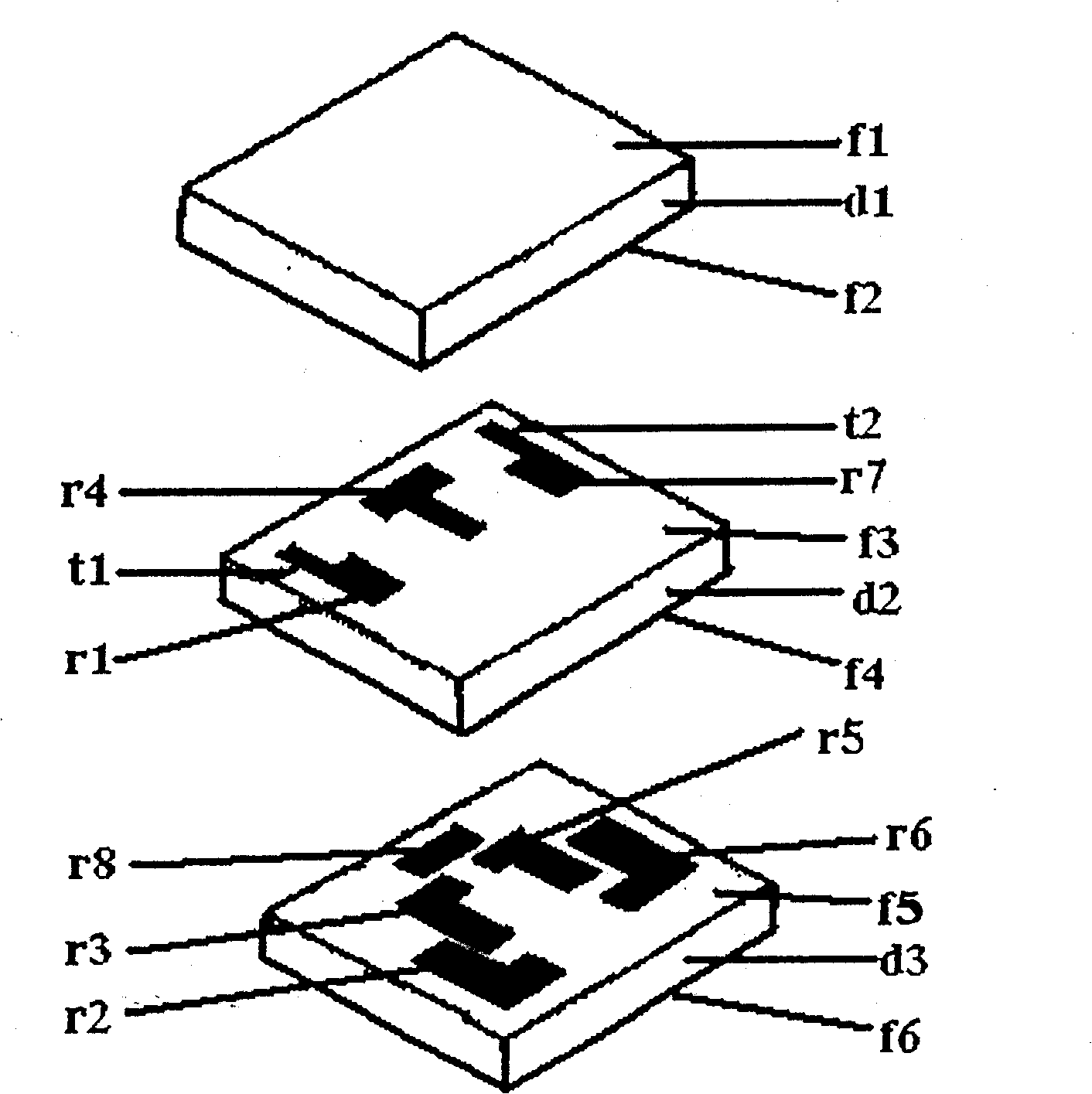

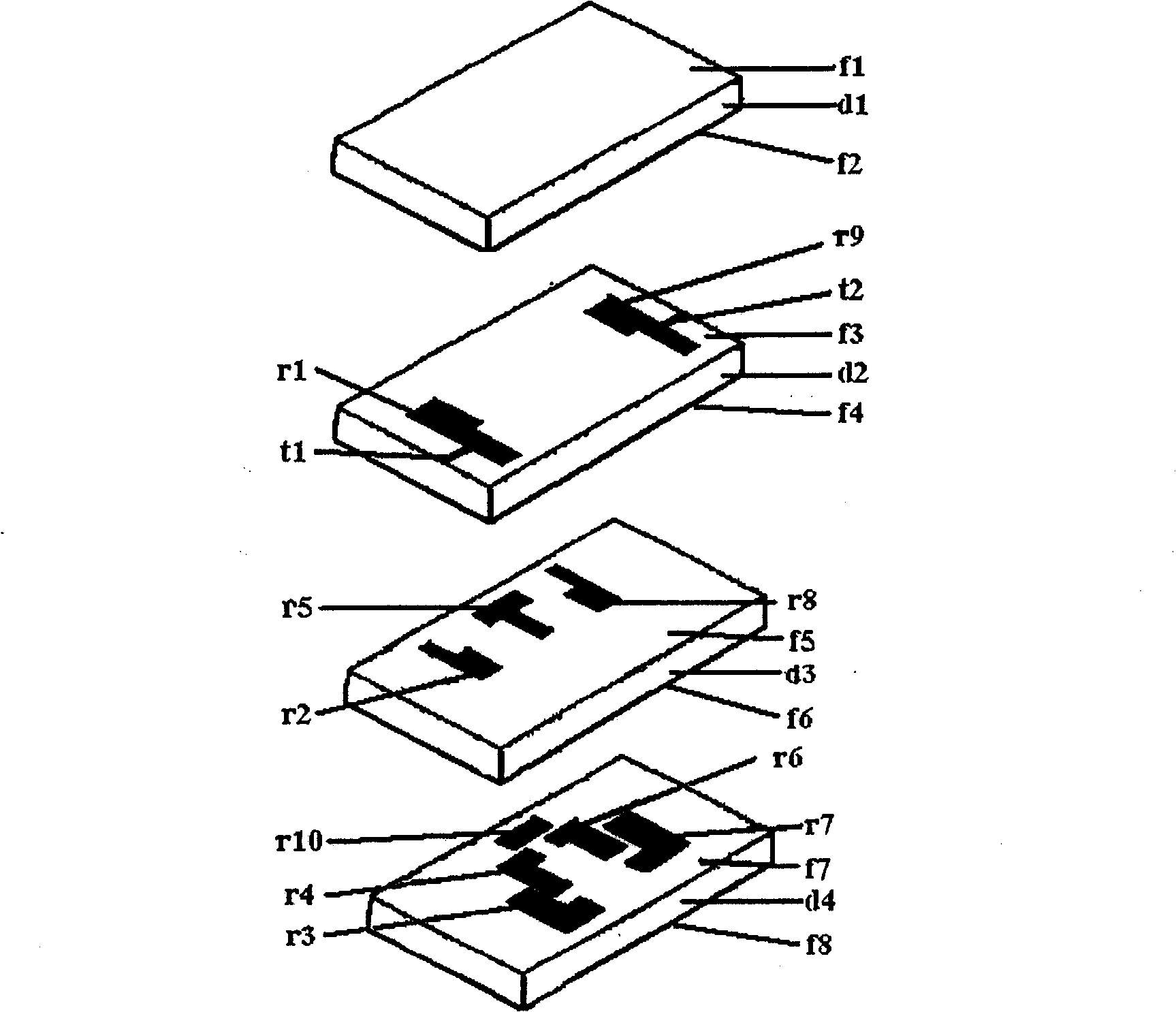

[0047] (1) The dielectric layer is a high-resistance silicon wafer, and a 3-layer stacked filter using a silicon-silicon bonding process:

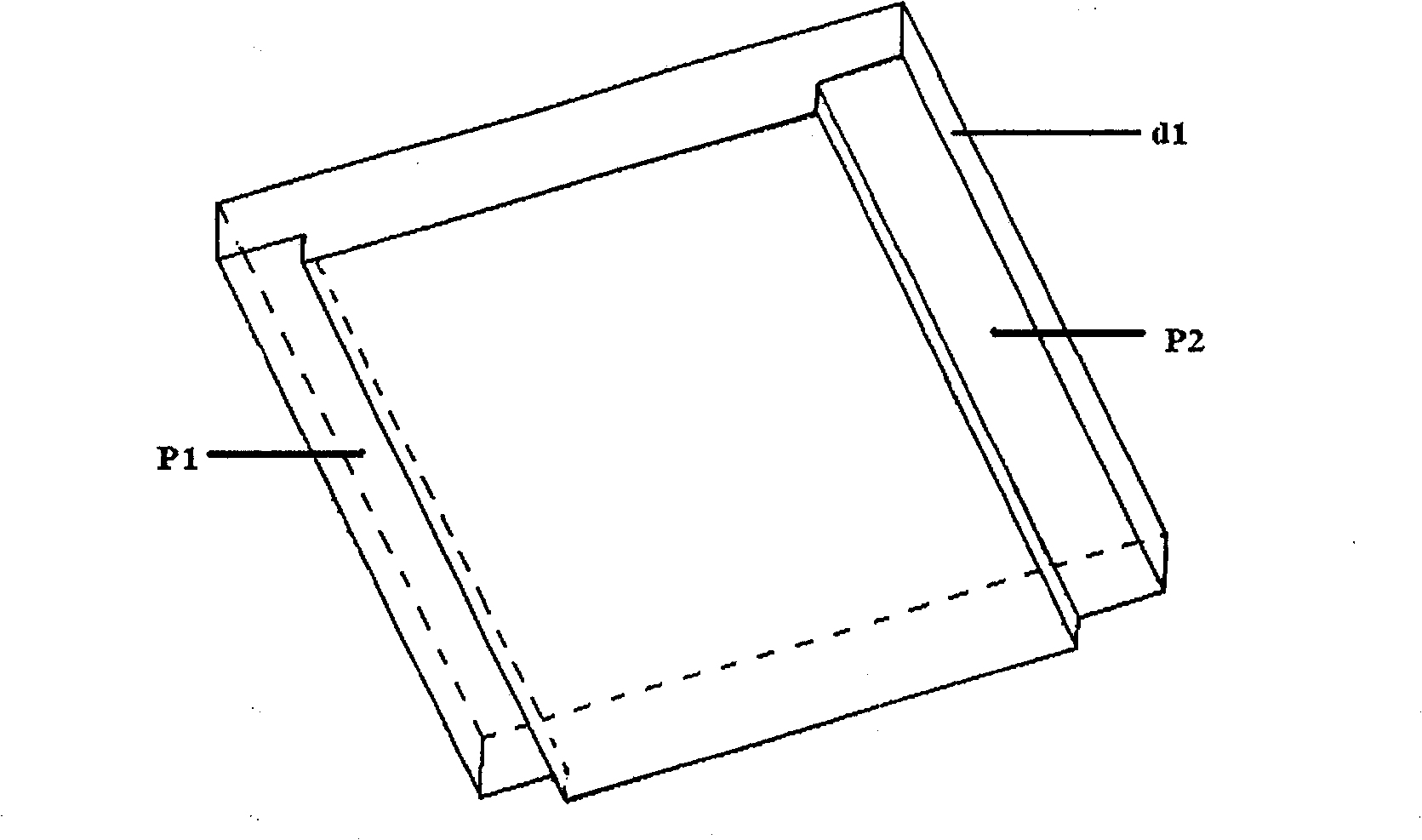

[0048] A Φ4″525μm thick silicon wafer with a resistivity of 3000Ω·cm is thinned to 400μm thick by grinding and polished to ensure a certain degree of flatness and smoothness. Form t1 and r1 on one surface by photolithography and etching processes , r4, r7, t2 patterns of shallow grooves and steps p1, p2. Among them, the shallow grooves of t1, r1, r4, r7, t2 patterns are about 5 μm deep; the steps p1, p2 are about 100 μm deep, and use photolithography and etching Process forms scribing and alignment mark pattern on its other side. Utilize photolithography and metallization process to form r1, t1, r4, r7, The metal transmission line pattern of t2, and the alignment mark pattern is formed on the other side by photolithography and etching process. The surfaces of the above two silicon wafers without alignment marks are bonded together, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com