Friction materials for high-speed train braking and method for preparing same

A friction material, high-speed train technology, applied in the direction of friction lining, mechanical equipment, etc., can solve the problems of poor wear resistance, friction performance decline, performance decline, etc., to achieve simple process, reduce high temperature performance decline, improve synergy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

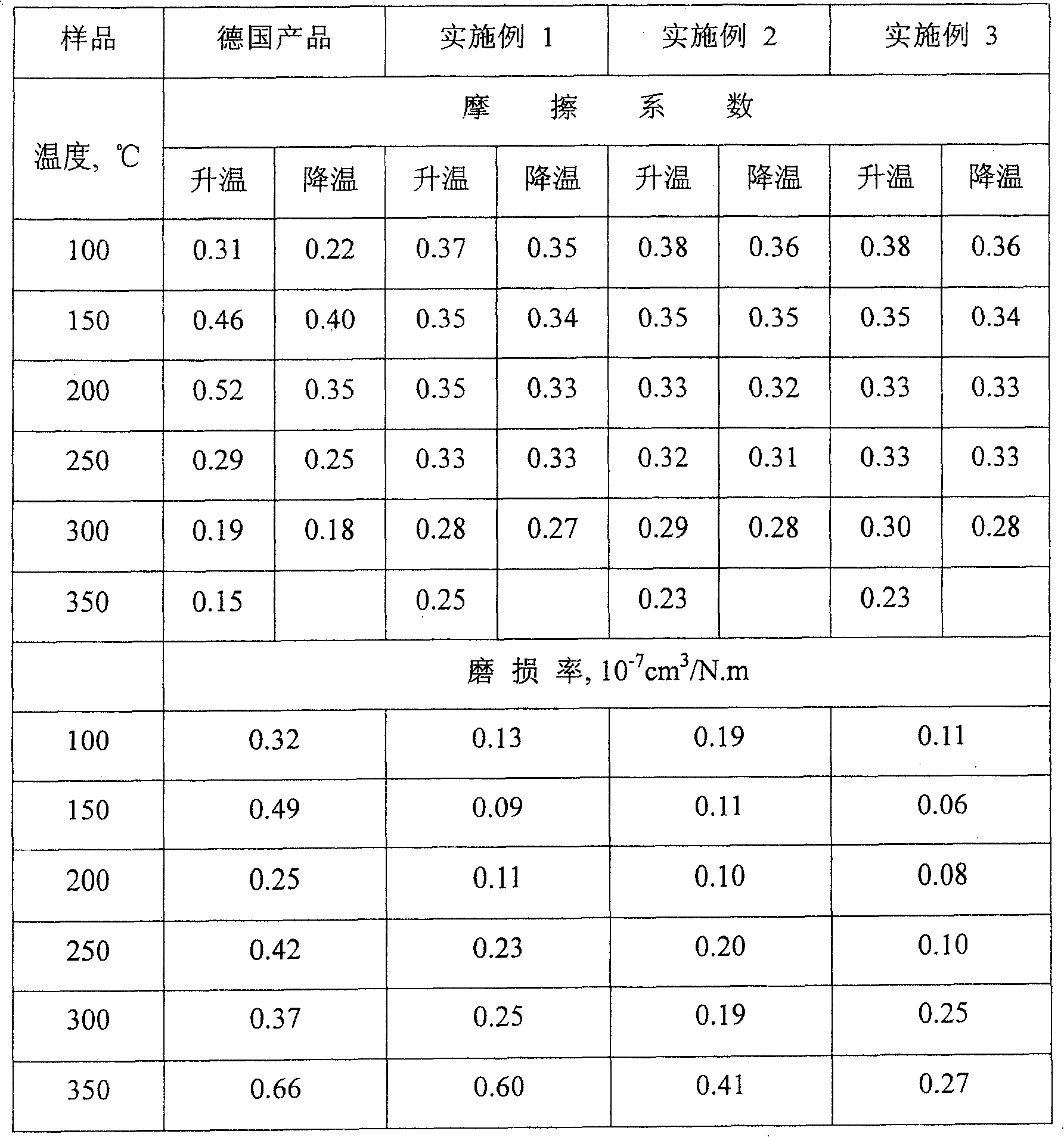

Examples

Embodiment 1

[0018] Embodiment 1, its component and parts by weight proportioning are:

[0019] 7 parts of styrene-butadiene rubber; 1 part of ferric oxide

[0020] 0.2 parts of rubber compounding agent; 0.3 parts of titanium dioxide

[0021] 8 parts of thermosetting phenolic resin; 0.3 parts of rare earth oxide of praseodymium and neodymium

[0022] 40 parts of friction powder; 0.3 parts of calcium fluoride

[0023] 10 parts of steel fiber; 1.0 parts of melamine cyanurate

[0024] Concrete preparation process steps are as follows:

[0025] 1) Weigh the raw materials according to the formula;

[0026] 2) Preparation of molding material: use an open mill for mastic refining of styrene-butadiene rubber, add rubber compounding agent after refining, and then add thermosetting phenolic resin for mixing; after mixing evenly, add friction powder, steel fiber, and ferric oxide , titanium dioxide, praseodymium and neodymium oxide rare earth mineral powder, calcium fluoride, melamine cyanurate,...

Embodiment 2

[0029] Embodiment 2, its component and parts by weight proportioning are:

[0030] 8 parts of nitrile rubber; 5 parts of copper fiber

[0031] 0.2 parts of rubber compounding agent; 4 parts of aramid fiber

[0032] 12 parts of thermoplastic phenolic resin; 0.5 part of ferric oxide

[0033] 46 parts of friction powder; 2 parts of carbon black

[0034] 0.3 parts of aluminum oxide; 0.5 parts of manganese dioxide

[0035] 0.5 parts of melamine cyanurate 3 parts of calcium fluoride

[0036] Steel fiber 4 parts Lanthanum-rich rare earth chloride 0.2 parts

[0037] Concrete preparation process steps are as follows:

[0038] 1) Weigh the raw materials according to the formula;

[0039] 2) Preparation of molding material: use an open mill for mastic refining of nitrile rubber, add rubber compounding agent after refining, and then add thermoplastic phenolic resin for mixing; after mixing evenly, add friction powder, aluminum oxide, melamine cyanuric acid Salt, copper fiber, arami...

Embodiment 3

[0042] Embodiment 3, its component and parts by weight proportioning are:

[0043] 9 parts of styrene-butadiene rubber; 7 parts of potassium titanate whiskers

[0044] 0.3 part of rubber compounding agent; 1 part of graphite

[0045] 9 parts of thermosetting phenolic resin; 2 parts of ferric oxide

[0046] 45 parts of friction powder; 0.3 parts of calcium fluoride

[0047] 5 parts of copper fiber; 0.3 parts of melamine cyanurate

[0048] 1 part of zinc oxide; 0.3 part of rare earth oxide of praseodymium and neodymium

[0049] Magnesium oxide 0.3 part Lanthanum-rich rare earth chloride 0.3 part

[0050] Concrete preparation process steps are as follows:

[0051] 1) Weigh the raw materials according to the formula;

[0052] 2) Preparation of molding material: use an open mill for mastic refining of styrene-butadiene rubber, add rubber compounding agent after refining, and then add thermosetting phenolic resin for mixing; after mixing evenly, add friction powder, copper fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com