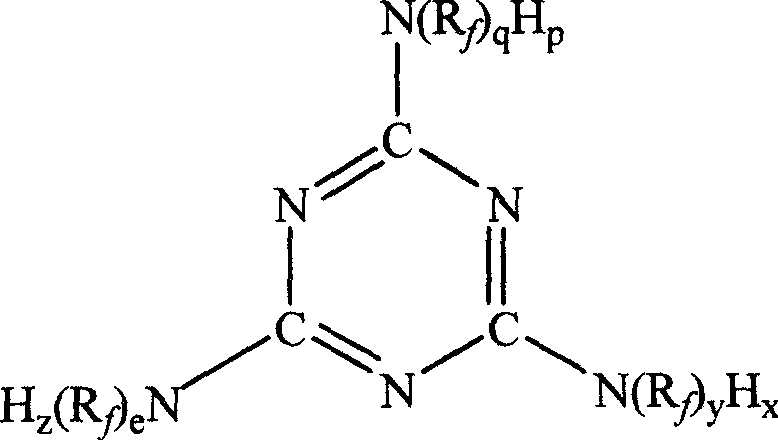

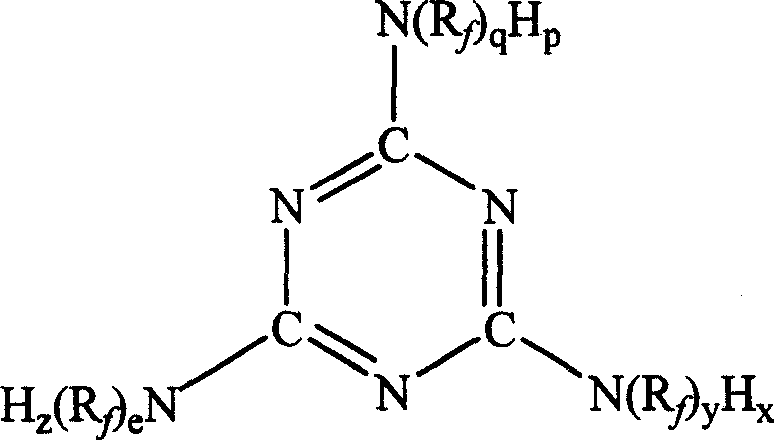

Perfluoro propionyl tripolycyanamide derivate and preparation process thereof

A technology of perfluoropropionyl and melamine, which is applied in organic chemistry and other fields, can solve the problems of poor weather resistance and low temperature resistance, and achieve the effect of reducing free radical concentration and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Put 12.6g (0.1mol) of melamine and 0.58g of KF in a 500ml three-necked round-bottom flask equipped with an ice-salt bath, mechanical stirring, and nitrogen protection device, add 250ml of anhydrous acetonitrile solvent to dissolve, keep the temperature at -10°C, and stir vigorously 104.8g (0.63mol) of hexafluoropropylene oxide was slowly passed through, and the passage was completed within 2 to 24 hours. After the passage was completed, continue to stir for 2 hours. After washing with methanol for many times, and then using deionized water for several times, vacuum 60 After drying at °C, a colorless oily liquid product was obtained with a yield of 94%.

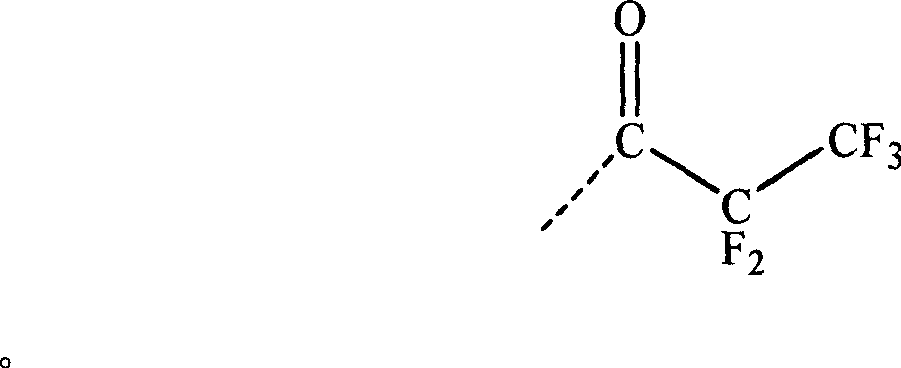

[0025] The product is tested by infrared spectrometer: at 1776cm -1 The characteristic absorption of the carbonyl group in the amide group substituted by α-fluorine at 979cm -1 There is a weak but sharp CF at 3 Characteristic absorption, while at 1000~1350cm -1 Then there is a continuous characteristic absorption of ...

Embodiment 2

[0031] Put 12.6g (0.1mol) of melamine and 0.58g of KF in a 1000ml three-necked round-bottom flask equipped with an ice-salt bath, mechanical stirring, and nitrogen protection device, add 500ml of anhydrous acetonitrile solvent to dissolve, keep the temperature at -25°C, and stir vigorously 104.8g (0.63mol) of hexafluoropropylene oxide was slowly passed through, and the passage was completed within 2 to 24 hours. After the passage was completed, continue to stir for 2 hours. After washing with methanol for many times, and then using deionized water for several times, vacuum 60 After drying at °C, a colorless oily liquid product was obtained with a yield of 97%. Others are the same as embodiment 1.

Embodiment 3

[0033] Put 12.6g (0.1mol) of melamine and 0.58g of KF in a 500ml three-necked round-bottom flask equipped with an ice-salt bath, mechanical stirring, and nitrogen protection device, add 250ml of anhydrous acetonitrile solvent to dissolve, keep the temperature at -25°C, and stir vigorously 104.8g (0.63mol) of hexafluoropropylene oxide was slowly passed through, and the passage was completed within 2 to 24 hours. After the passage was completed, continue to stir for 2 hours. After washing with methanol for many times, and then using deionized water for several times, vacuum 60 After drying at °C, a colorless oily liquid product was obtained with a yield of 96%. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com