Synthesis of boron-contained silicone

A synthesis method and technology of polysilane, which is applied in the field of synthesis of boron-containing polysilane, can solve the problems of difficult control of reaction rate, severe reaction conditions, and lack of commercial production, and achieve high-temperature oxidation resistance improvement, simple operation, and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

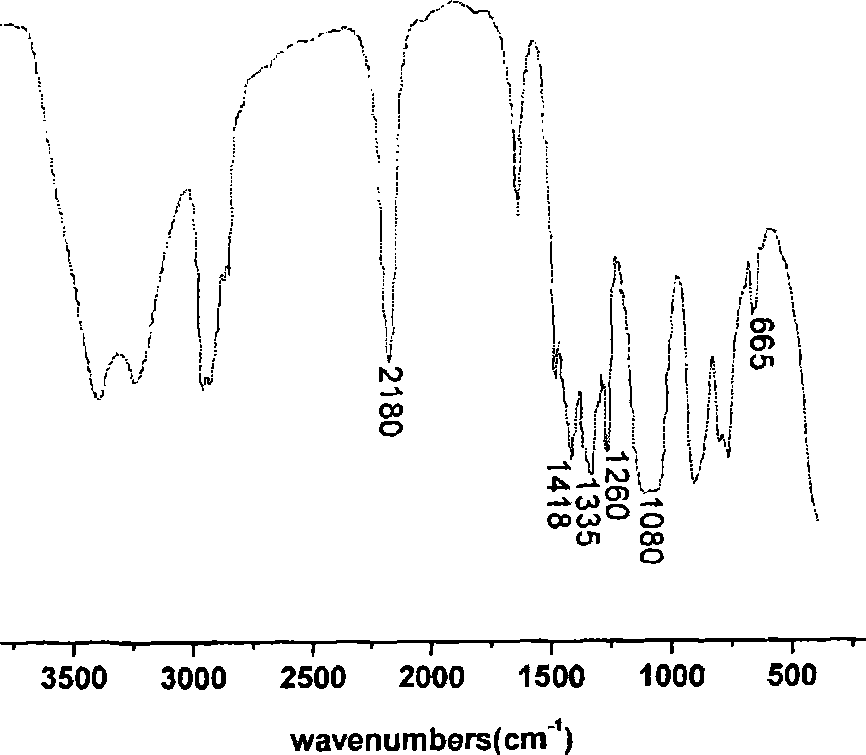

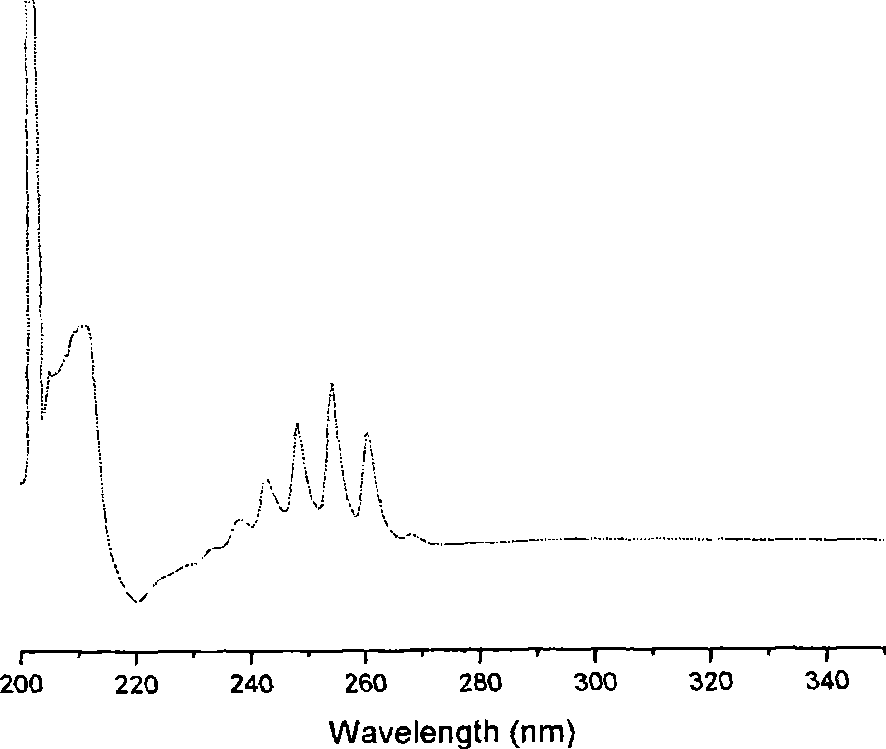

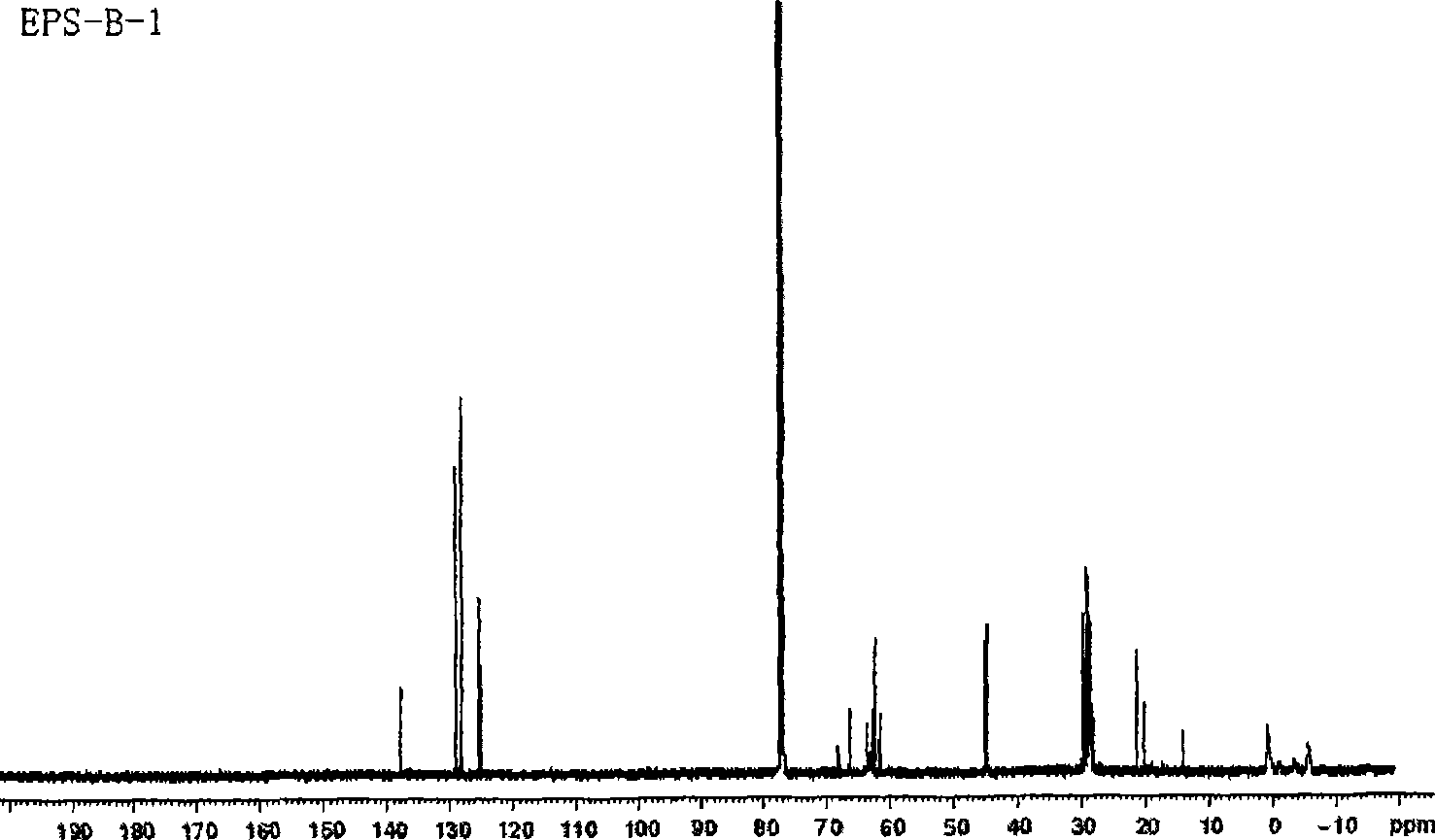

[0025] Embodiment 1: In an electrochemical reaction flask equipped with a ventilation tube, a stirrer and a thermometer, add methylhydrogendichlorosilane and boron trifluoride ether solutions in different molar ratios. Then add about 130ml of tetrahydrofuran (add a small amount of sodium for dehydration and distill, take a fraction at 66°C) and lithium perchlorate (LiClO) with a concentration of 0.1mol / L 4 ) as the supporting electrolyte. Magnesium blocks are used as cathode and anode. After three times of vacuuming and nitrogen filling, start stirring and ultrasonic wave, and then turn on the electricity to start the reaction. When the reaction power reaches 1340mA*h, stop the electricity, add 200ml of toluene, and pass in a gas bag of ammonia to neutralize the remaining Si-Cl bonds. At this time, observe the change of the thermometer in the reaction bottle, and the temperature will increase with the introduction of ammonia gas. When the thermometer shows a stable reading an...

Embodiment 2

[0031] Example 2: Using boron-containing polysilane as a precursor to prepare a C / C-B-SiC composite material containing a B-SiC matrix, and using H 2 -O2 The ablation properties of C / C and C / C-B-SiC composites were compared by flame method. The density is 1.19g cm -3 The C / C composite material has been impregnated three times, and the density has been increased to 1.50g cm -3 . The change of its density with the number of immersions is shown in Table 2. Figure 4 , Figure 5 The ablation experimental results of C / C-B-SiC composites after dipping three times are given, and the ablation results of C / C are also given for comparison. Density 1.19g·cm -3 The C / C sample was impregnated once to obtain 1.31g·cm -3 C / C-B-SiC, its line ablation rate and mass ablation rate are lower than the density of 1.5g cm -3 C / C. As the density of C / C-B-SiC composites increases, the linear ablation rate and mass ablation rate gradually decrease. When the density of the material increases fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com