High-curing modified-guar-gum-contained aqueous solution and preparing method

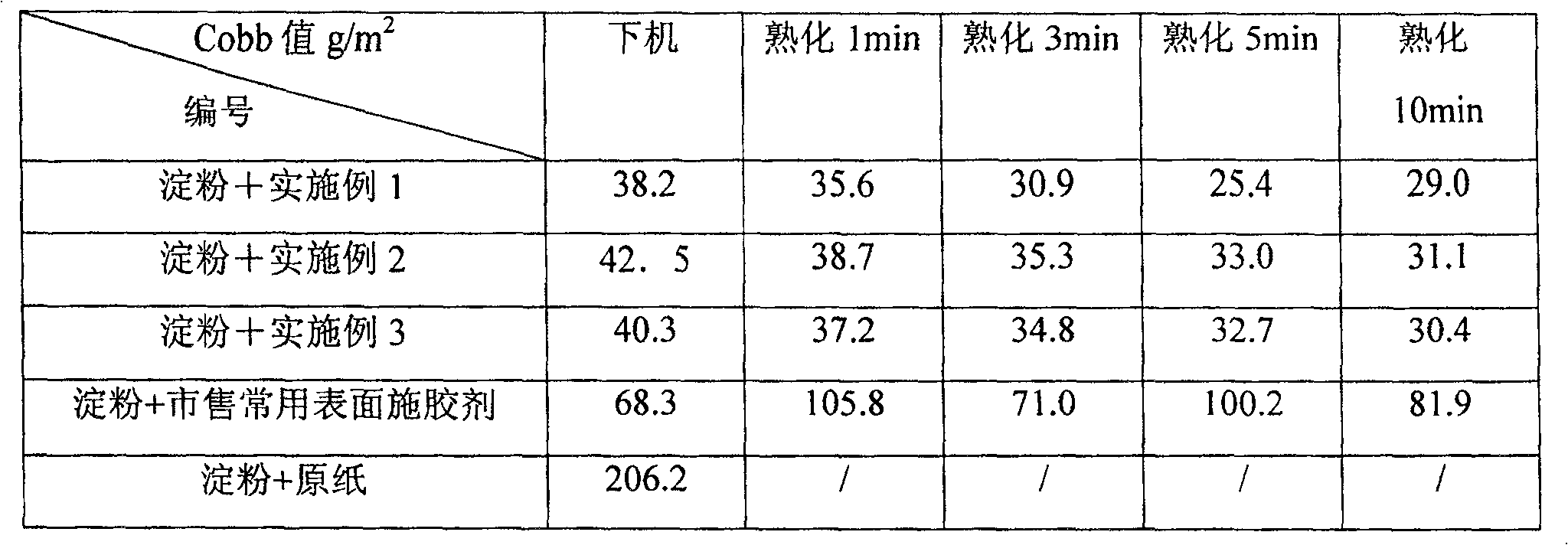

A water solution and guar gum technology, applied in the direction of water-repellent addition, inorganic compound addition, paper, etc., can solve the problems of high water-insoluble content, difficult industrialization and mass production of preparation methods, and slow dissolution speed, reaching Cobb The effect of lowering the value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 200 grams of ethanol with a volume concentration of 95% into a 1000 ml four-neck flask, turn on electric stirring, take 100 grams of guar collagen powder (10% water content) and disperse it, and adjust the pH to pH=10 with 0.05N sodium hydroxide. Add 8 grams of hydrogen peroxide (30%) with a dropping funnel and heat up to 80°C, react for 3 hours and cool down to 35°C, add 32 grams (25%) of lye, add 18 grams of 3-chloro-2-hydroxypropyl Trimethylammonium chloride, heated to 60°C for 5 hours, then cooled to 30°C, and neutralized to pH=8 with acetic acid. Vacuum filter the reaction product, wash the filter cake twice with 80% ethanol, filter, dry and pulverize to obtain a milky white powder with a water content of 10%. (the degree of cationic substitution of the gained modified guar gum powder is 0.1, measured by GB12309-90).

[0029] Add 62.4 grams of deionized water into a 500ml four-necked round-bottomed flask, turn on electric stirring, disperse 32 grams (water con...

Embodiment 2

[0031] Add 200 grams of methanol into a 1000 ml four-necked flask, turn on electric stirring, take 100 grams of guar collagen powder (10% water content) and disperse it, and adjust the pH to pH=11 with 0.05N potassium hydroxide. Add 10 grams of hydrogen peroxide (30%) at one time and heat up to 65°C, cool down to 35°C after 6 hours of reaction, add 37 grams (25%) of potassium hydroxide lye at one time, add 30 grams of epoxypropyl three For methyl ammonium chloride, heat up to 70°C for 5 hours, then cool down to below 30°C, and neutralize with hydrochloric acid to PH=8. Vacuum filter the reaction product, wash the filter cake twice with 80% ethanol, filter, dry and pulverize to obtain a milky white powder with a water content of 10%. (the degree of cationic substitution of the gained modified guar gum powder is 0.2, measured by GB12309-90)

[0032] 76 grams of water are added in a 500ml four-necked round-bottomed flask, and 18 grams (10% of water content) of the above-mentione...

Embodiment 3

[0034] Add 200 grams of isopropanol into a 1000 ml four-necked flask, turn on electric stirring, take 100 grams of guar collagen powder (10% water content) and disperse it, and adjust the pH to PH=11 with the supernatant of saturated calcium hydroxide solution. Add 5 grams of hydrogen peroxide (30%) at one time and heat up to 85°C, cool to 35°C after 5 hours of reaction, add calcium hydroxide slurry (25%) slurry at one time, add 10 grams of 4-chloro-2 -butenyltrimethylammonium chloride, heat up to 40°C for 3 hours, then heat up to 70°C for another 2 hours, then cool down to below 30°C, neutralize with citric acid to pH=8. Vacuum filter the reaction product, wash the filter cake twice with 80% ethanol, filter, dry and pulverize to obtain a milky white powder with a water content of 10%. (the degree of cationic substitution of the gained modified guar gum powder is 0.05, measured by GB 12309-90)

[0035]Add 115 grams of deionized water into a 500ml four-necked round-bottomed fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com