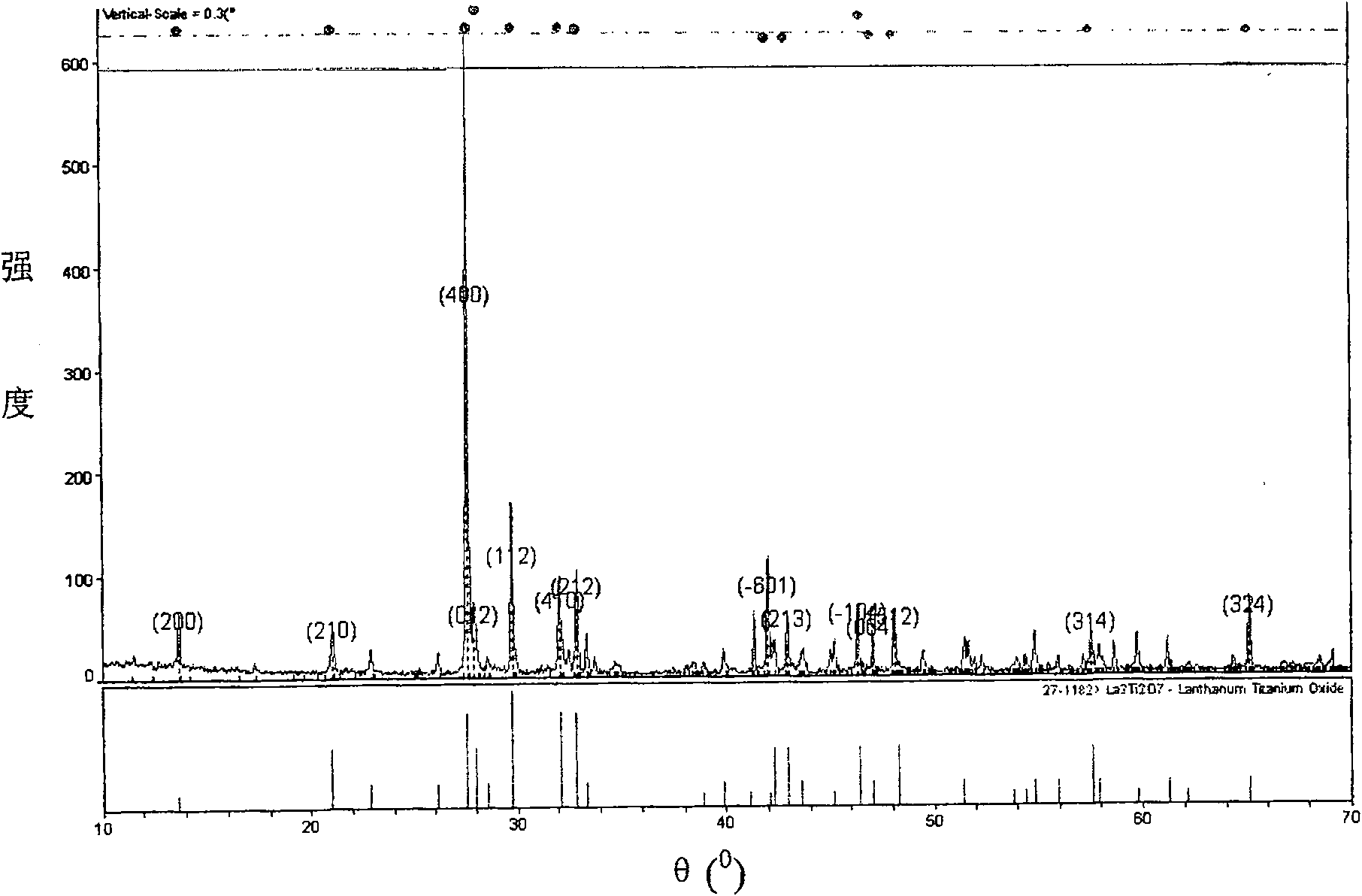

Lanthanum titanates single-crystal upgrowth technology

A technology of lanthanum titanate and crystal growth, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of easy introduction of impurities, difficulty in ensuring composition and structure uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

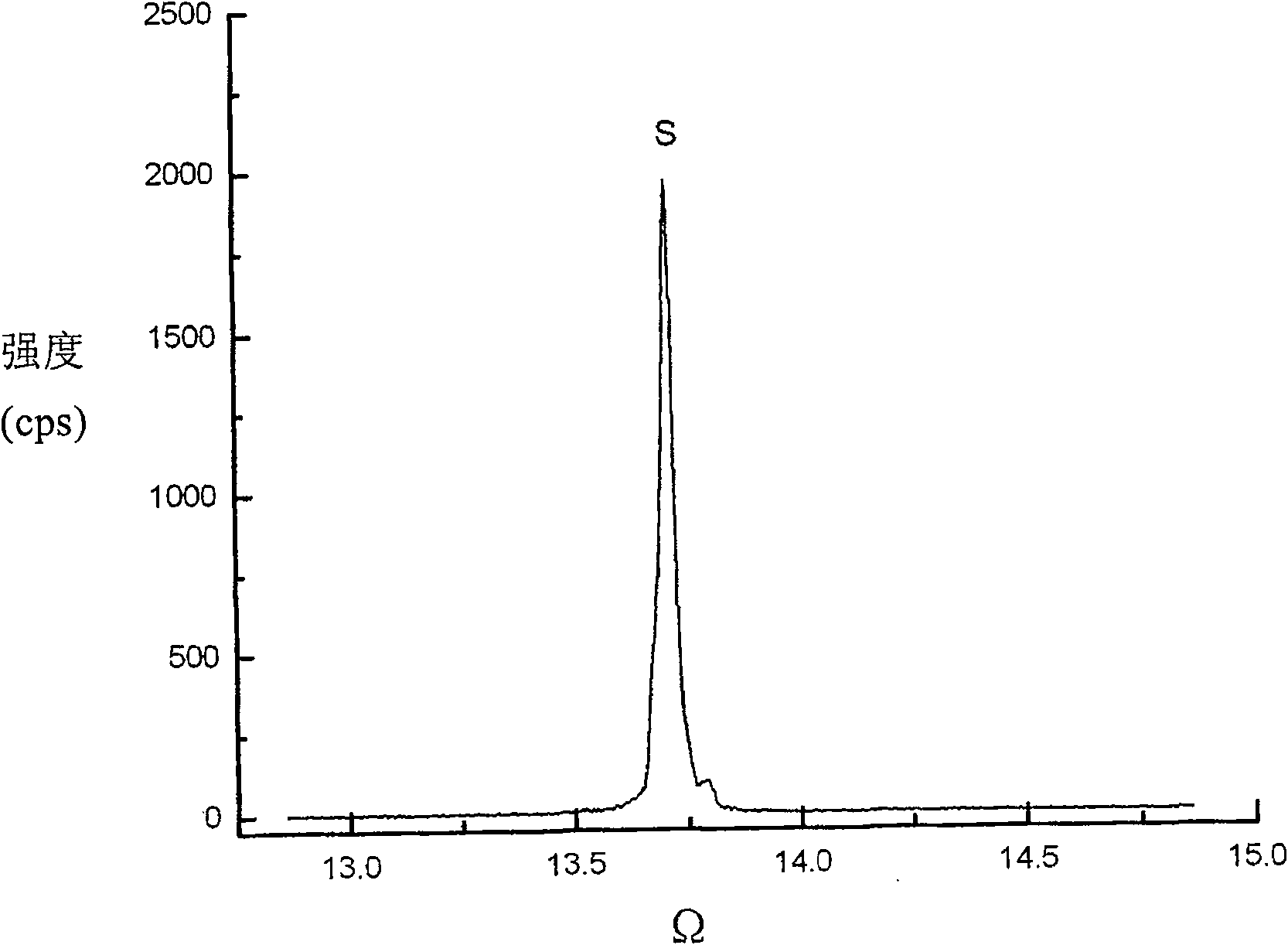

Embodiment 1

[0049] TiO with a purity of 99.9 wt% 2 and 99.999wt% La 2 o 3 Press La 2 Ti 2 o 7 The chemical composition ingredients are mixed, and the mixed powder is ground and mixed evenly on a mortar or grinder, at 2t / cm 2 Pressed into a pellet under isostatic pressure; then placed in a cylindrical crucible together with a seed crystal of the selected orientation . The crucible is placed in the descending furnace and adjusted to a certain height. After the whole system is sealed, it is energized and heated up. The mechanical pump and the diffusion pump are started successively, and the vacuum is pumped to 10 -3 Pa, when the furnace temperature reaches 1500°C, fill it with 99.99% by volume of argon, continue to heat up to 1850°C, melt the raw material and adjust the position of the furnace to melt the top of the seed crystal, perform inoculation and growth, and the temperature gradient of the growth interface is maintained at 30 ℃ / cm, lower the crucible at a rate of 3 mm / h, and gro...

Embodiment 2

[0052] TiO with a purity of 99.99wt% 2 and 99.999wt% La 2 o 3 Press La 2 Ti 2 o 7 The chemical composition ingredients are mixed, and the mixed powder is ground and mixed evenly on a mortar or grinder, at 3t / cm 2 Pressed into cubes under the isostatic pressure; and then placed into a rectangular cylindrical crucible together with a rectangular cylindrical seed crystal in the direction. The crucible is placed in the descending furnace and adjusted to a certain height. After the whole system is sealed, the temperature is energized and the vacuum is pumped to 10 -4 Pa, when the furnace temperature reaches 1600°C, fill it with 99.99% by volume argon, continue to raise the temperature, control the furnace temperature at 1900°C, melt the raw material and inoculate and grow, the temperature gradient of the growth interface is about 60°C / cm, and the temperature gradient is 8.8mm / The crucible is lowered at a rate of h, and a rectangular columnar LTO complete crystal is grown. ...

Embodiment 3

[0054] TiO with a purity of 99.9 wt% 2 and 99.999wt% La 2 o 3 Press La 2 Ti 2 o 7 The chemical composition ingredients are mixed, the mixed powder is ground and mixed evenly on a mortar or grinder, and pressed into a round block; respectively put into three crucibles with a diameter of 70mm, and then placed in a high-temperature drop furnace with three crucible positions, adjust After reaching a certain height, the whole system is sealed and energized to heat up, and then vacuumed to 10 -2 Pa, when the furnace temperature reaches 1700°C, fill it with 99.99% by volume argon, continue to raise the temperature, and control the furnace temperature at 1950°C. Adjust the furnace entry positions of the three crucibles so that the seed crystals in each crucible can be inoculated well. The temperature gradient of the growth interface is about 70°C / cm, and the crucible descending rate is 1.0mm / h. Three cylinders can be obtained at the same time. like LTO crystals. After the cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com