Manufacturing method of Fe-Ni50series alloy powder and magnetic powder core

A technology of alloy powder and manufacturing method, which is applied in the field of Fe-Ni50 series alloy powder and magnetic powder core manufacturing, can solve the problems of high internal resistance, low loss, unspecified magnetic permeability and AC-DC superposition performance, etc., to improve the resistivity , the effect of reducing power loss and improving filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

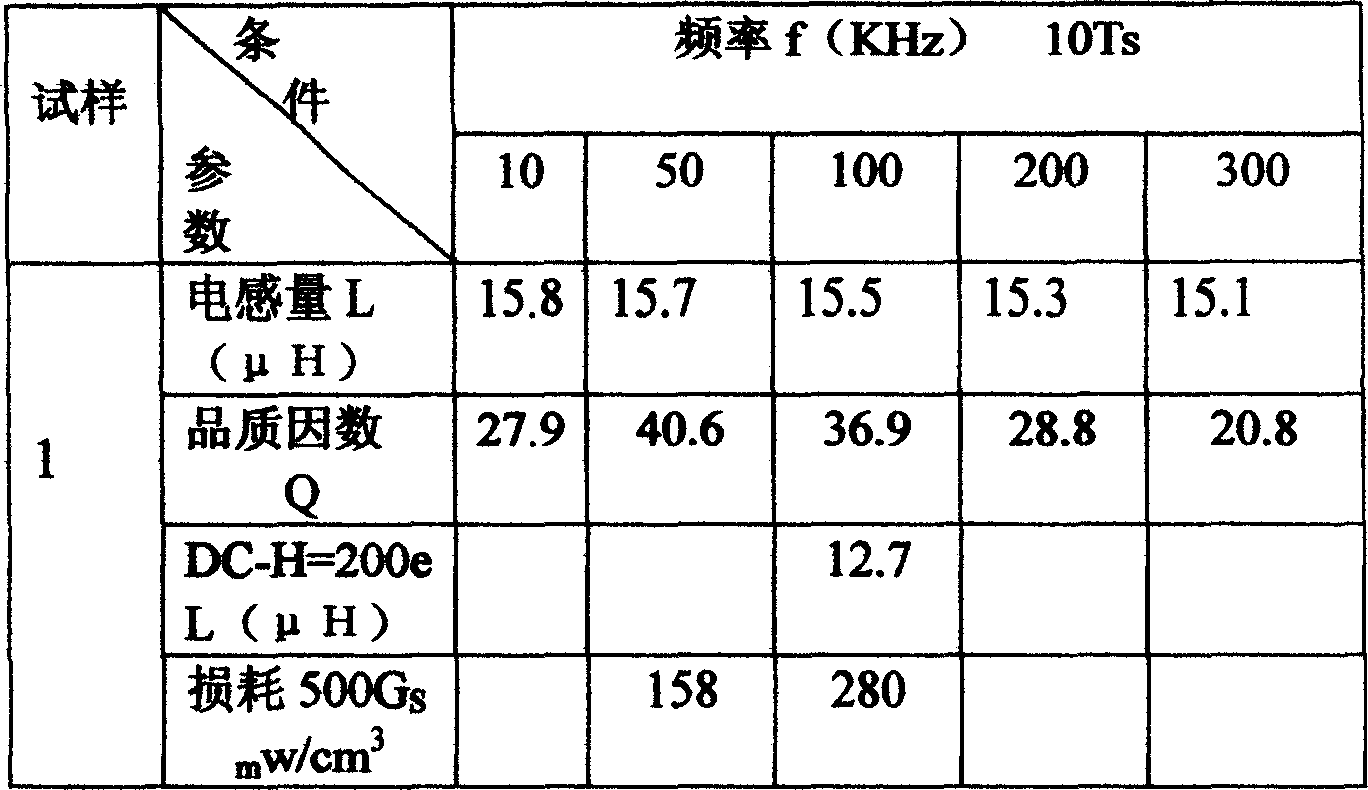

Embodiment 1

[0017] Put industrial pure iron, nickel plate, metal manganese, and sponge titanium into an induction furnace protected by nitrogen gas for smelting, and the chemical composition of smelting is 49-50% nickel, 0.1-0.6% manganese, 0.1-0.6% titanium, and Mn+Ti≥ 0.6%, the rest is iron alloy steel liquid, spray the liquid steel into -100 mesh powder by water spray cooling method, dry the powder at about 100 ℃, process it into flakes by mechanical method, enter the heat treatment furnace, under the protection of hydrogen , 800°C±20°C reduction treatment for 2-4 hours, after cooling, sieve it, according to 100-200 mesh, it accounts for 10±5%, 200-320 mesh accounts for 50±5%, and the rest is fine powder less than 320 mesh. Adjust the particle size of the powder, and then passivate the surface of the powder with an acidic solution to form a coating film on the surface of the alloy powder, use fine mica powder or kaolin for insulation, the dosage is 0.2-1.0%, and use sodium silicate solu...

Embodiment 2

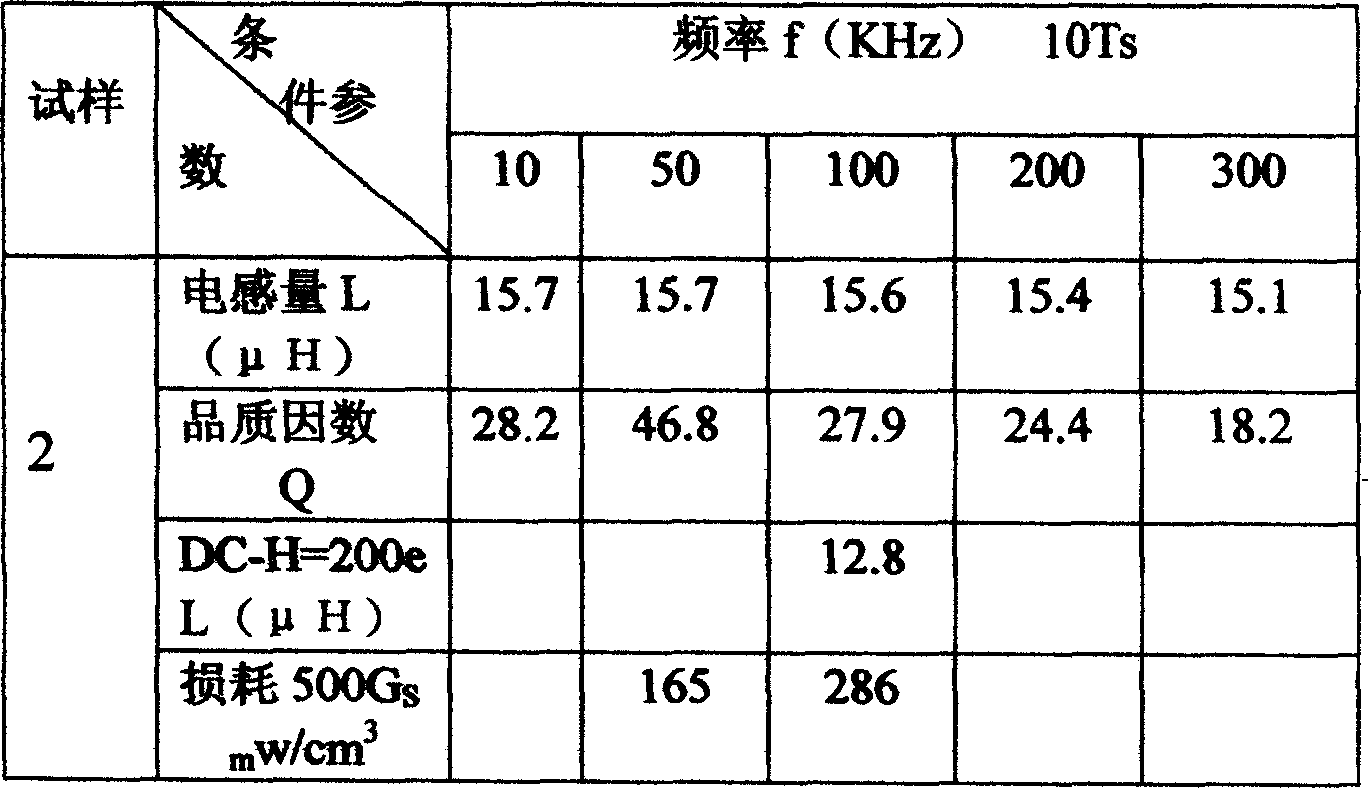

[0019] Embodiment 2: The process procedure is the same as that of Example 1, and its alloy composition is: Ni: 49.6%, Mn: 0.5%, Ti: 0.2%, and the balance is Fe. The basic parameters of its magnetic properties are shown in Table 2:

[0020] The data in Table 2 shows that, compared with Example 1, the content of Mn and Ti has some changes, the decrease of magnetic permeability after AC superimposition does not change much, and the loss slightly increases, but is lower than that of commercial products.

Embodiment 3

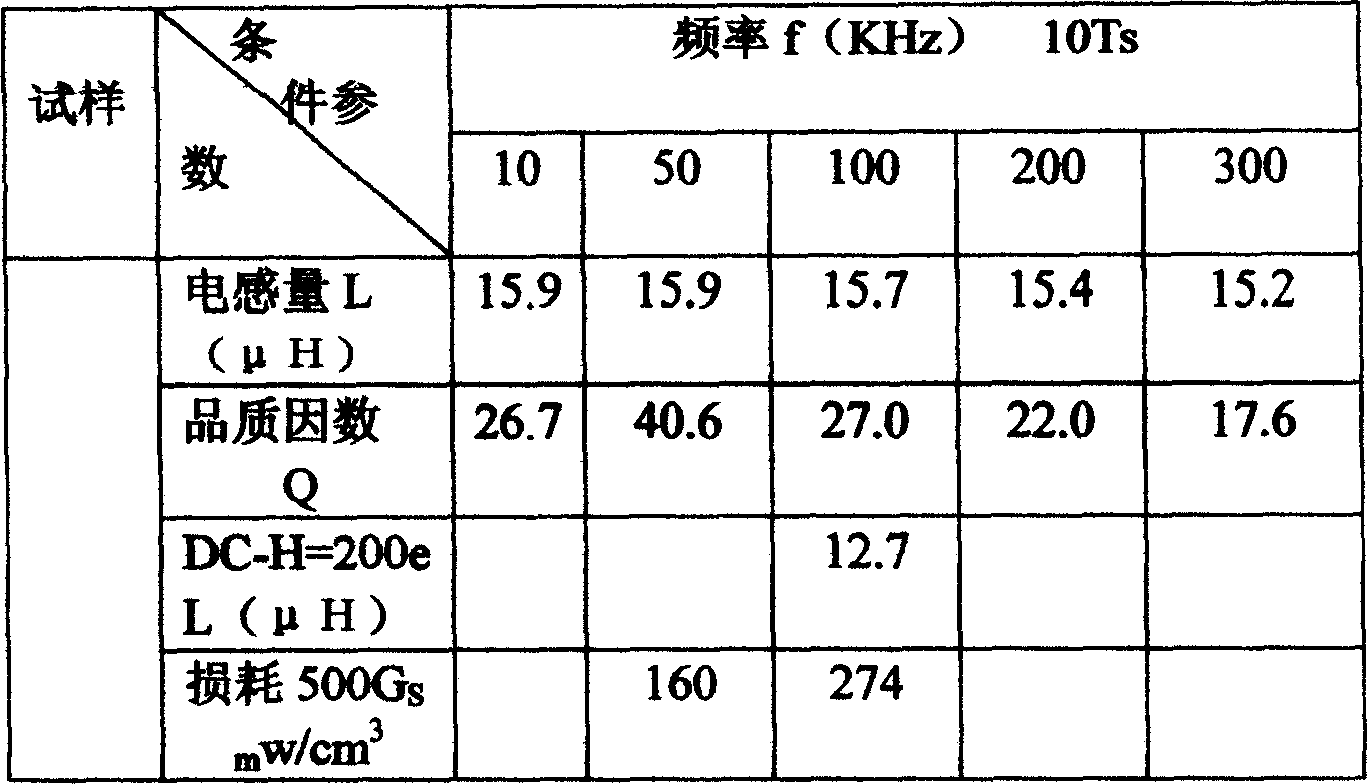

[0022] The process procedure is the same as that of Example 1, and its alloy composition is: Ni: 49.8%, Mn: 0.4%, Ti: 0.6%, and the remainder is Fe. The basic parameters of its magnetic properties are shown in Table 3:

[0023] The data in Table 3 shows that compared with Example 1, the contents of Mn and Ti have increased, and the magnetic permeability after AC superimposition decreases slightly faster, μe=81%μ 0 Its loss decreased slightly, which may be the effect of finer grains.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen content | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com