Use of bi-alkyl carboxylate surface activator in triple oil recovery

A technology of alkyl carboxylate and surfactant, which is applied in the field of anionic surfactant gemini alkyl carboxylate, and achieves the effects of low production cost, simple preparation process and small adsorption loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

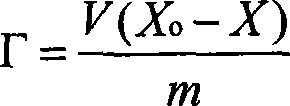

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: the synthesis of double fourteen

[0065] ①Synthesis of myristyl chloride

[0066] Take 20-32g of myristic acid and 12.5-21.3g of thionyl chloride, stir and react for 2-4h, then reflux at 70-90°C until no gas is produced in the tail gas drying tube. Then the excess thionyl chloride was evaporated under reduced pressure, and then distilled under reduced pressure, the distillate was myristyl chloride.

[0067] ②Synthesis of intermediate ethylenediaminediacetic acid

[0068] Chloroacetic acid 10-19g, water 30-50ml, anhydrous sodium carbonate 7-9g to obtain sodium chloroacetate solution.

[0069] Anhydrous ethylenediamine 2.5-4.5g, water 20-45ml, sodium chloroacetate solution 12-25g. After constant temperature for 24h, reflux at 70-80°C for 2-4h to keep the solution pH = 8-9. After vacuum distillation at 60-70°C, add concentrated hydrochloric acid to the concentrated solution until pH = 1-2, white precipitate Generated, washed 3 times with distilled water ...

Embodiment 2

[0072] Example 2: Shuanglaurel composite oil displacement system, indoor simulated oil displacement

[0073] ①Formulation: 0.06wt% dilaurel, 0.24wt% complex alkali (Na 2 CO 3 : NaHCO 3 =1:1 mass ratio), 0.2wt% partially hydrolyzed polyacrylamide (HPAM), 99.5wt% mineralized water.

[0074] The partially hydrolyzed polyacrylamide has a molecular weight of 18 million and a degree of hydrolysis of 28 wt%, a product of Shengli Oilfield Polymer Co., Ltd., the same below.

[0075] ②Basic data of artificial core:

[0076] Experimental temperature: 60°C; air permeability: 1.34μm 2 ;Pore volume: 40cm 3 ; Saturated oil volume: 39cm 3 ;

[0077] The properties of Gudao River beach crude oil are as mentioned above;

[0078] ③Test process:

[0079] Slug design:

[0080] Formula system slug: 0.3PV;

[0081] Protection slug: 0.2wt% HPAM, 0.05PV; 0.05wt% HPAM, 0.05PV;

[0082] Generally, there are at least two slugs in the oil displacement process, the former is the oil displacemen...

Embodiment 3

[0085] Example 3: double fourteen compound oil displacement system, indoor simulated oil displacement

[0086] ①Recipe: 0.06wt% double fourteen, 0.24wt% compound alkali (Na 2 CO 3 : NaHCO 3 =1:1 mass ratio), 0.2wt% HPAM, 99.5wt% mineralized water.

[0087] 2. The basic data and test process of the artificial rock core are as described in Example 2;

[0088] ③Test results:

[0089] Water flooding recovery: 61.1wt% OOIP; chemical flooding recovery: 15.1wt% OOIP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com