Poly L-glutamic acid-poly N-isopropylacrylamide graft copolymer and preparation method thereof

A technology of isopropyl acrylamide and graft copolymer, which is applied in the field of poly-L-glutamic acid-poly-N-isopropyl acrylamide graft copolymer and its preparation, can solve the problem of unseen copolymer, polyamino acid Problems such as the lack of reports on co-polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: Preparation of poly-L-glutamic acid homopolymers with different molecular weights.

[0055] (1) Weigh 5 parts of 0.076mol of γ-benzyl-L-glutamate-N-carboxylic acid anhydride (BLG-NCA) monomer into 5 dry reaction flasks, add 400ml of dry dioxane respectively The ring dissolves the monomer. Under vigorous stirring, 0.015, 0.0076, 0.0038, 0.0030 and 0.00076 mol of triethylamine were added, and the solution was allowed to stand at room temperature for 72 hours. The product was settled with ethanol, filtered, washed, and vacuum-dried at room temperature for 24 hours to obtain five kinds of polyγ-benzyl-L-glutamate homopolymers with different molecular weights. The yield is 81-92%.

[0056] (2) 5 kinds of poly-γ-benzyl-L-glutamate obtained in (1) are respectively weighed 10g, dissolved in 150ml dichloroacetic acid respectively, and 30ml hydrogen bromide content is added respectively at room temperature and is 33wt% Hydrogen bromide / glacial acetic acid solution (...

Embodiment 2

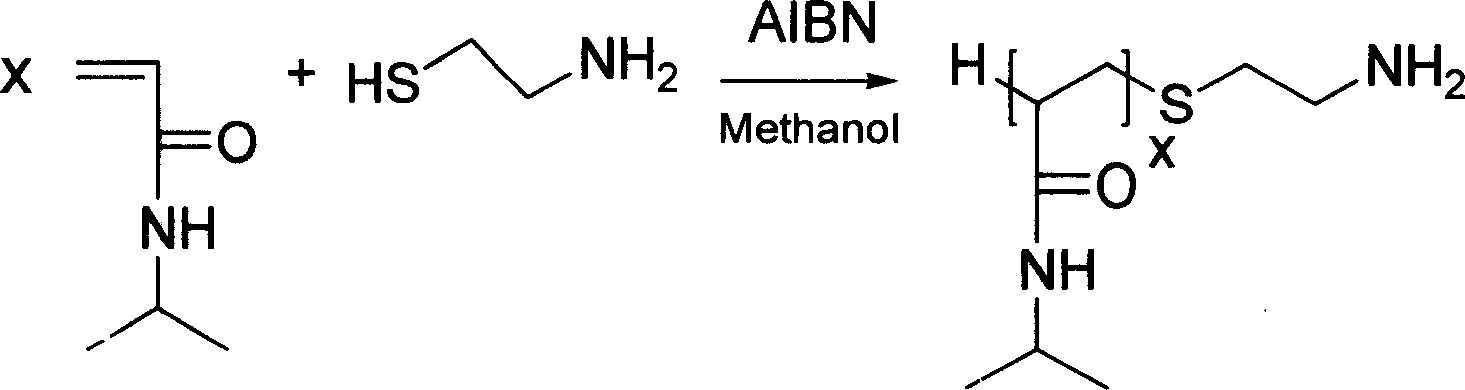

[0059] Example 2: Preparation of poly-N-isopropylacrylamide homopolymers with different molecular weights and one terminal being an amino terminal.

[0060]Weigh 4 parts of 0.2mol of N-isopropylacrylamide and 0.002mol of azobisisobutyronitrile, add them to 4 reaction ampoules respectively, then add 0.003, 0.006, 0.012 and 0.02mol of Mercaptoethylamine. After dissolving with 40ml of methanol respectively, the gas in the bottle was removed through 3 freeze-vacuum-melt cycles, and the ampoule was sealed. The solution was stirred at 50, 60, 60 and 80°C for 24 hours, and the product was settled with excess ether, filtered, washed, and vacuum-dried to obtain poly-N-isopropylacrylamide homopolymers of different molecular weights with one end being an amino terminal. The results are shown in Table 2.

[0061] Numbering

[0062] In the above table, A / I / T refers to the molar ratio of N-isopropylacrylamide monomer / azobisisobutyronitrile / mercaptoethylamine; DP (PNIPAM) is the...

Embodiment 3

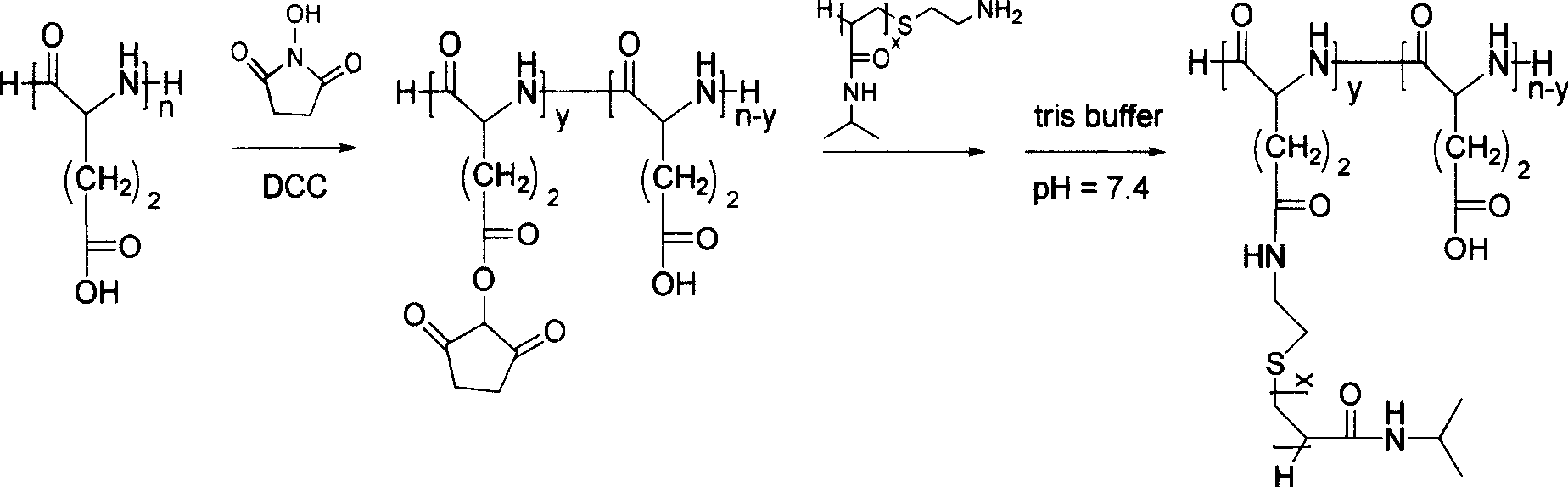

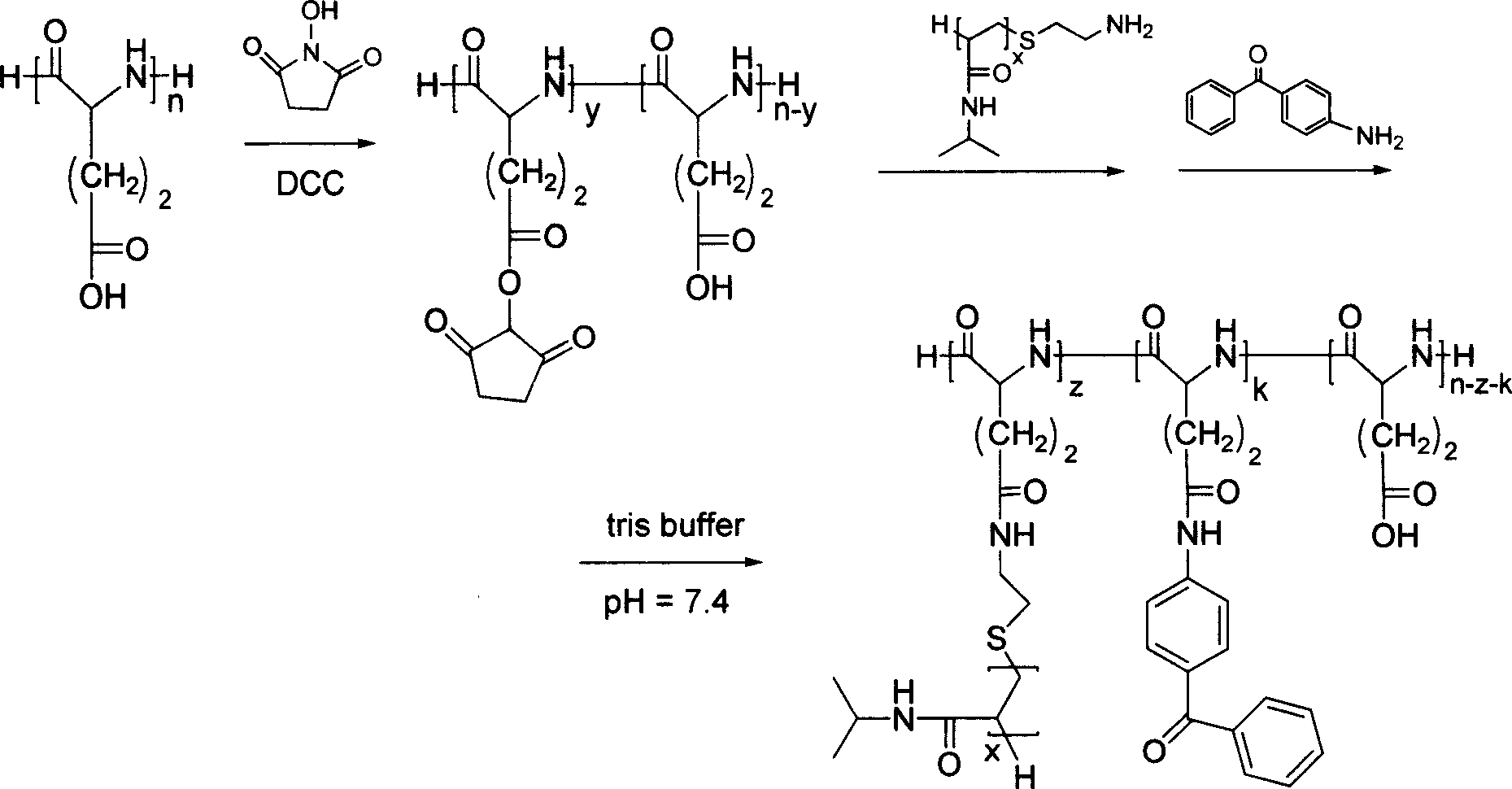

[0063] Example 3: Poly L-glutamic acid-poly N-isopropylacrylamide graft copolymer was synthesized by using an oil-soluble coupling agent and N-hydroxysuccinimide (NHS) to activate the carboxyl group.

[0064] Add 0.2g of poly-L-glutamic acid (viscosity-average molecular weight 27800Da, DP=215) and N-hydroxysuccinimide (NHS) into reaction ampoules with different numbers, and the amount of N-hydroxysuccinimide See Table 3 for the molar ratio of the amino-terminal poly-N-isopropylacrylamide that is expected to be added. Add 10ml of N, N-dimethylformamide to gradually dissolve the solid, cool the solution to 0°C, and add N-hydroxyl Dicyclohexylcarbodiimide in an equimolar amount of succinimide was stirred at room temperature for 24 hours. Then, 0.25 g of poly-N-isopropylacrylamide (number-average molecular weight: 1800 Da, DP=15) with one terminal being an amino terminal was added, and the reaction was continued to stir at room temperature for 72 hours. After the reaction, filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com