Environment-friendly type technique for vanadium extraction of stone coal

A process and environmental protection technology, applied in the direction of vanadium oxide, etc., can solve problems such as pollution and environmental impact, and achieve the effects of reducing environmental pollution, high recovery rate, and low material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

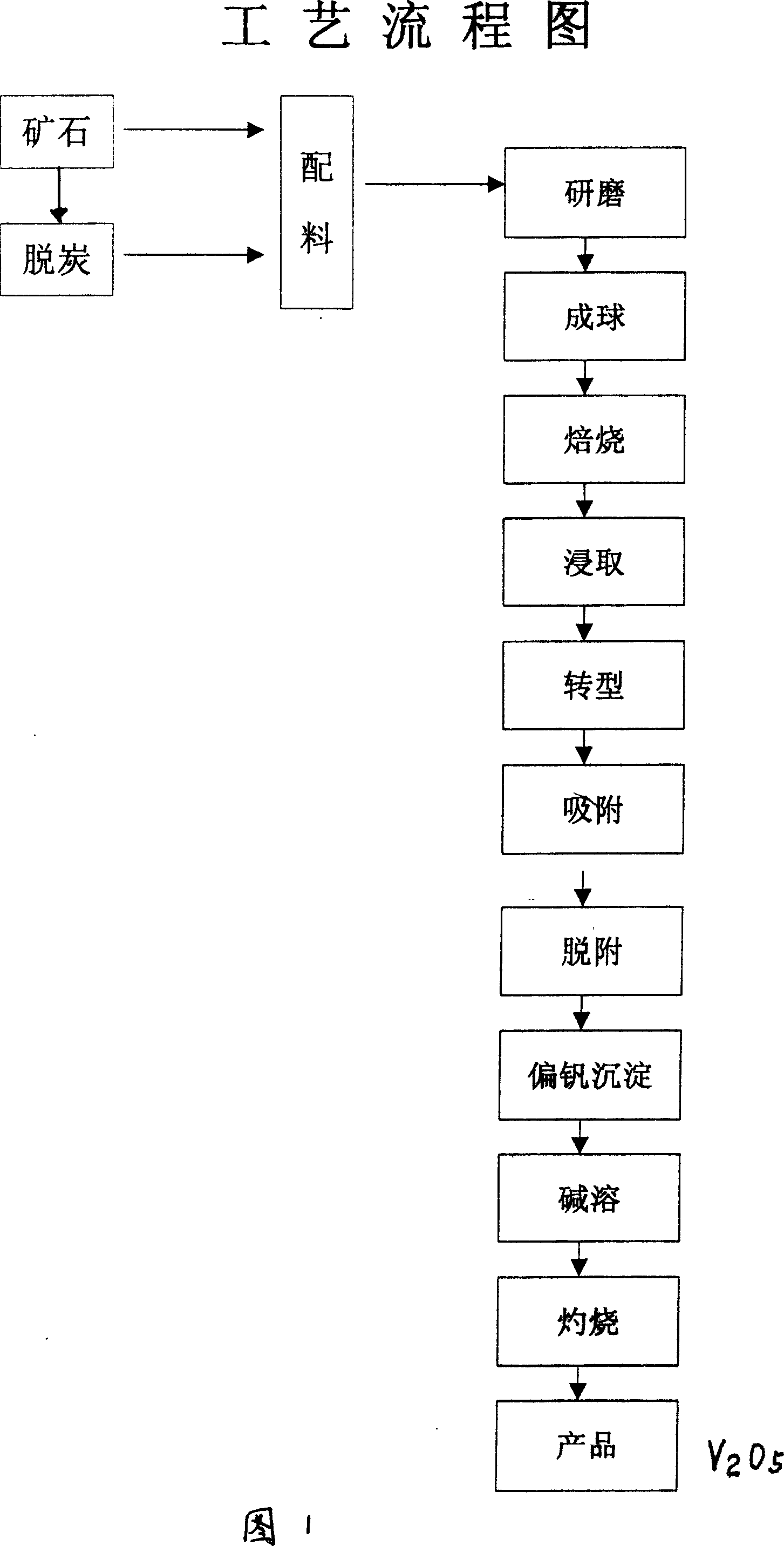

[0041] The new environment-friendly process for extracting vanadium from stone coal is as follows:

[0042] 1. Raw material processing

[0043] ①Decarbonization: decarbonize the ore in a flat kiln or fluidized fluidized furnace;

[0044] ②Batching: batching of decarbonized ore and non-decarbonized ore;

[0045] ③ Crushing: crush the prepared ore to make its particle size meet the particle size requirements of the ball mill;

[0046] ④ Grinding: Ball mill the crushed ore, and control the particle size below 0.15mm;

[0047] ⑤Balling: The ground ore is made into balls to make ore balls with a diameter of 15-20mm.

[0048] Some of the mined ore will be decarbonized. The purpose of decarburization is to remove excess carbon in the ore, and control the calorific value of the ore to be roasted at about 400 kcal / kg, so as to avoid reducing the conversion rate of water-soluble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com