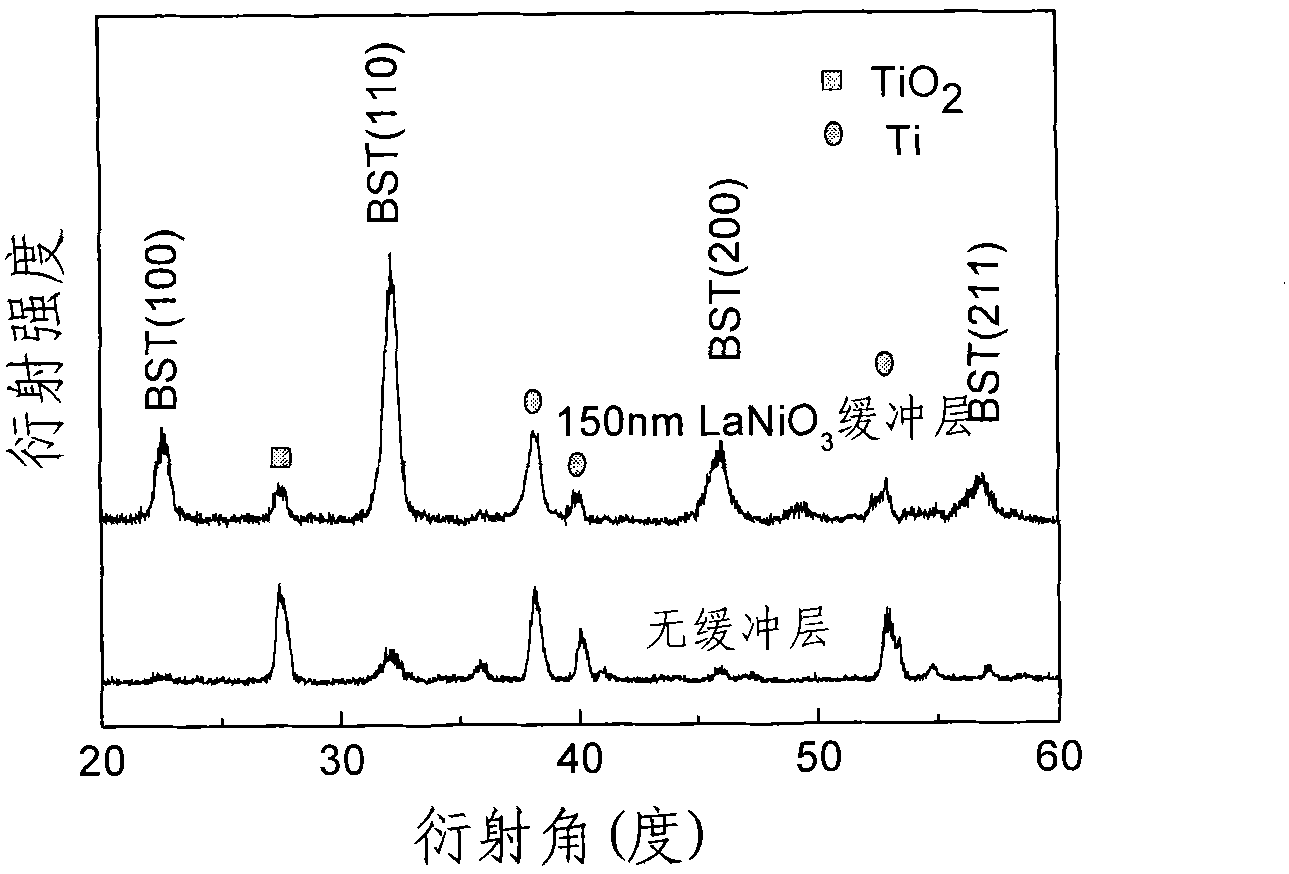

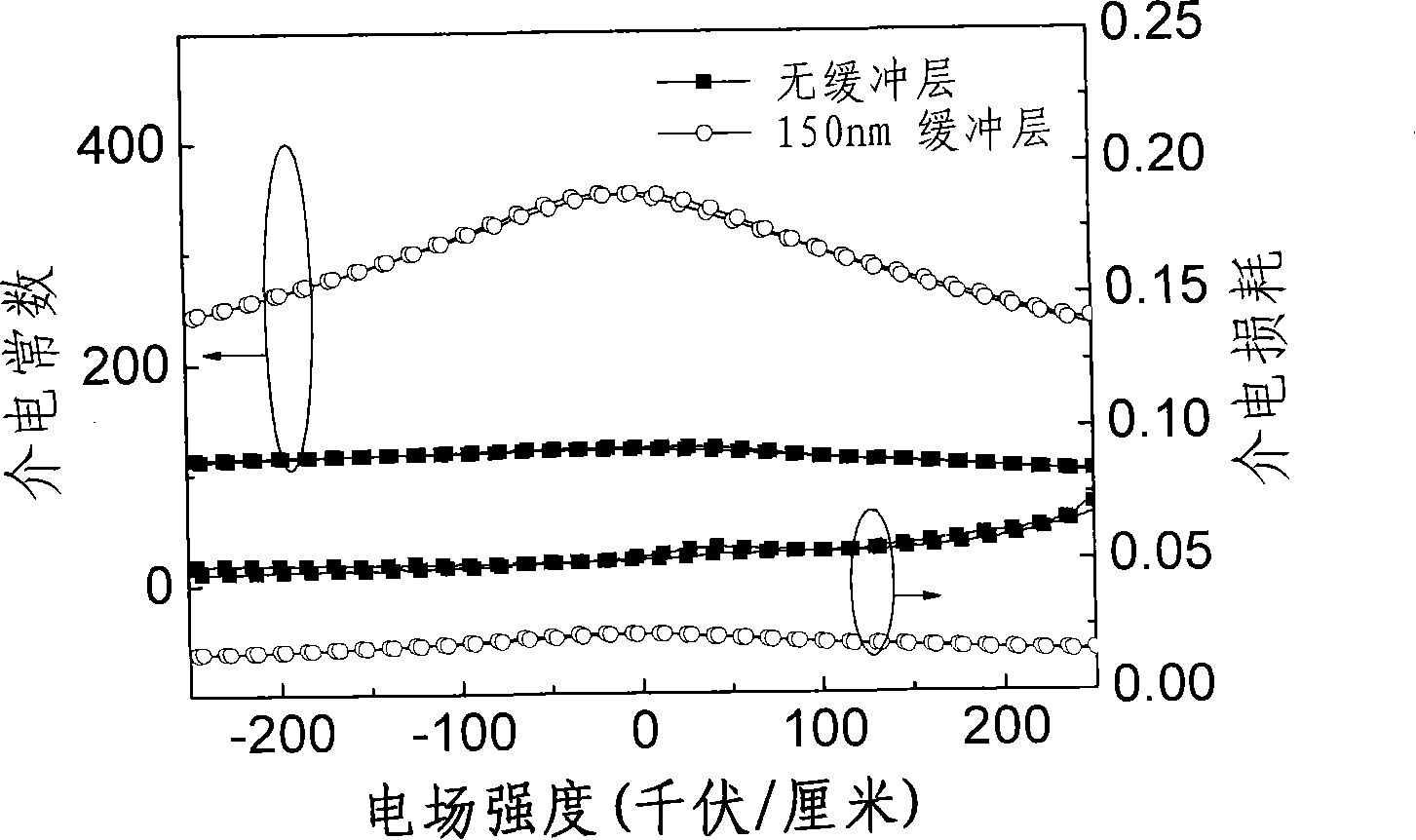

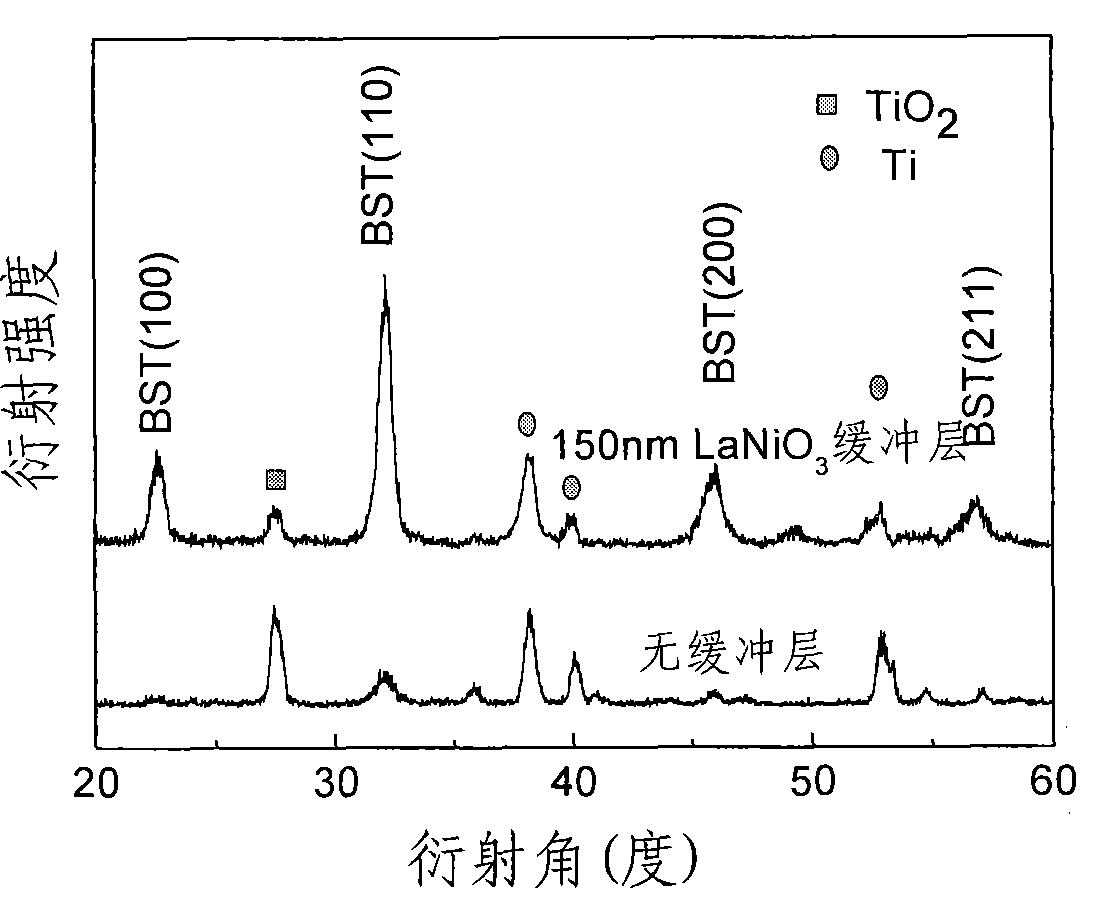

Method for growing barium strontium titanate on metal titanium-based substrate

A technology of barium strontium titanate and metal titanium, which is applied in the field of growing barium strontium titanate thin films, can solve the problems of reduced film performance, complicated process, easy oxidation, etc., and achieves the effects of improving crystallinity, good thermal stability and good crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment one: the technical process and steps of this embodiment are as follows

[0020] (1) Pretreatment of the titanium substrate: First, mechanically polish the 10×10mm titanium substrate to obtain a flat and smooth surface, then perform ultrasonic cleaning with deionized water, acetone, and absolute ethanol in sequence, and dry it for later use.

[0021] (2) Preparation of sol

[0022] ① Preparation of lanthanum nickelate (LNO) sol: Weigh 1.7448 g of nickel nitrate and 2.2222 g of lanthanum nitrate, add 5 ml of deionized water and stir at 90°C for 2 hours, then lower the solution to 70°C, and then add 0.2777 g of polyethylene Alcohol, stirred for 1 hour, finally cooled to 65°C, then added 15ml of acetic acid, stirred for 24 hours, and finally got 0.3mol / L LaNiO 3 Sol 20ml, spare.

[0023] ② Preparation of barium strontium titanate (BST) sol: Weigh 2.7778 grams of tetrabutyl titanate, add 5 ml of ethylene glycol methyl ether, and stir at 85 ° C for 3 hours; then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com