Abrasive corrosive-resisting butterfly valve, its production and forming mould

A kind of butterfly valve, anti-corrosion technology, applied in the direction of lift valve, valve device, mechanical equipment, etc., can solve the problem of not resistant to chloride ion corrosion, increase replacement frequency, large area of anti-corrosion lining, etc., to improve wear resistance and resistance Corrosion performance, increase the sealing interference, and improve the effect of bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

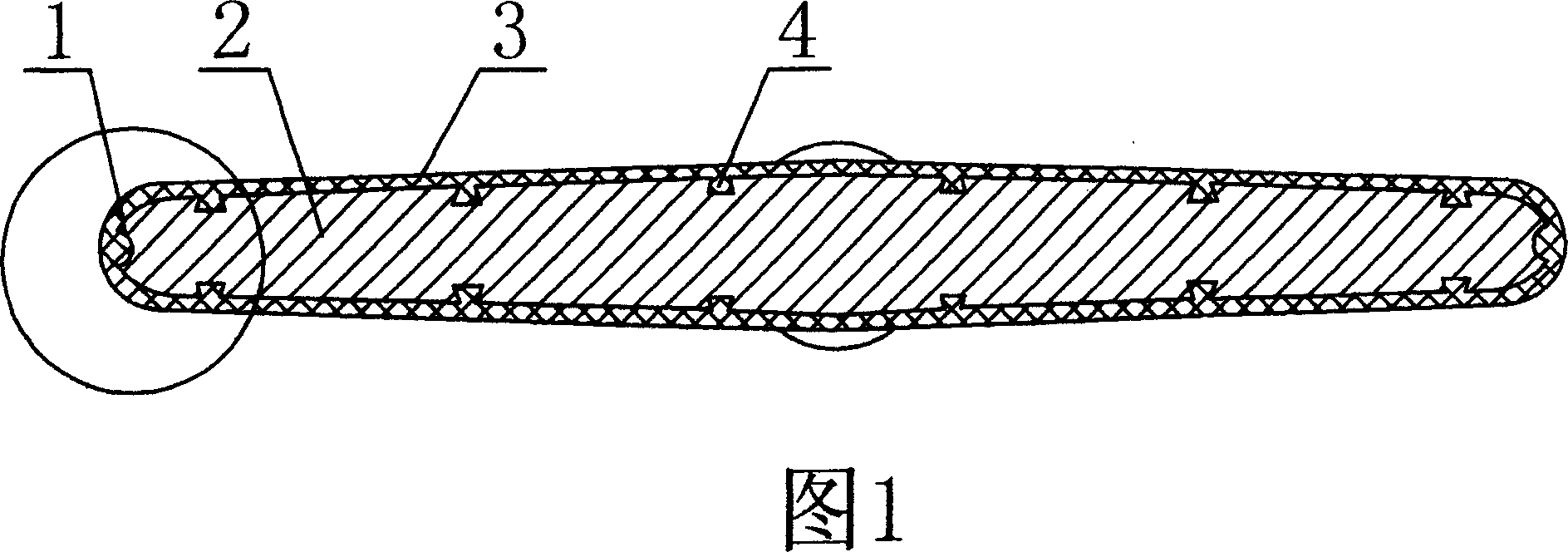

[0033] Embodiment 1: Referring to Fig. 1, the wear-resistant and corrosion-resistant butterfly valve of the present invention has a metal valve plate 2 with an anchoring cladding pit 4 processed on the surface, and an annular groove 1 on the thickness surface of the peripheral surface, which is formed by casting Covered with castable acid and alkali resistant polyurethane elastomer 3. The body is lined with a polyethylene plastic liner.

[0034]Valve plate casting coating, see Figure 9, the pouring mold is composed of an upper mold 14 and a lower mold 15 that are asymmetrically cut according to the height of the cavity, so that the parting surface 17 deviates from the centerline of the thickness of the valve plate, and the outer periphery of the upper mold is smaller. The lower mold is large and has positioning steps, which are positioned and fixed by the ring 16, and the cavity surface is designed according to the coating thickness. Wherein the protruding support 20 that is ...

Embodiment 2

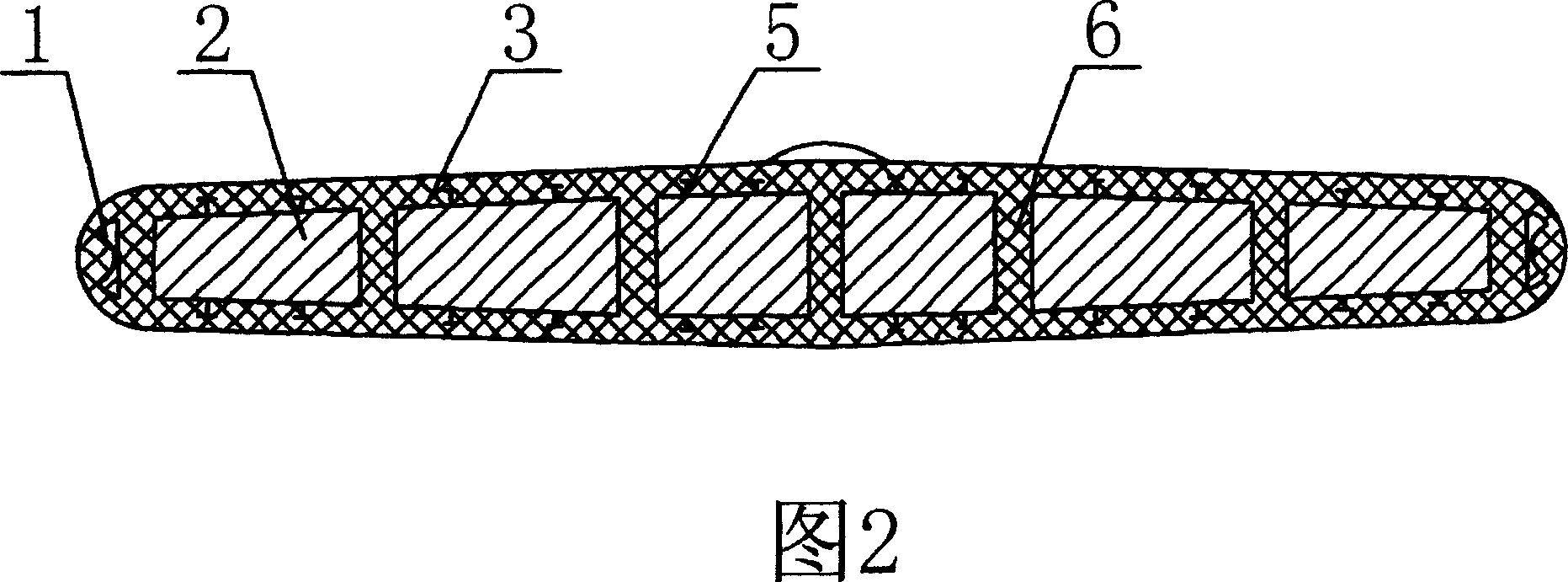

[0035] Embodiment 2: Referring to Figures 2, 5, and 6, as mentioned above, the anchoring cladding on the valve plate surface is arranged in a circular arrangement of through holes 6 and / or bosses 5 . The flow-through wall of the valve body 9 is welded with a block-shaped metal mesh 10 , and then lined with a plastic layer or a polyurethane elastomer layer 11 .

[0036] Casting type acid and alkali resistant polyurethane elastomer, obtained by polymerization of polycaprolactone and isocyanate (MDI), adding a compound chain extender with a total amount of 13% of the prepolymer, of which 12% of the chain extender is added for the first time 1,4 -butanediol, 3.6% trimethylolpropane, a second addition of 59.4% hydroquinone-bis(β-hydroxyethyl) ether (HOEE), and 25% resorcinol-bis(β- Hydroxyethyl) ether, the stirring reaction is completed within one minute, and injected into the mold. It is possible to obtain a polyurethane coating layer with a service temperature up to 130°C and be...

Embodiment 3

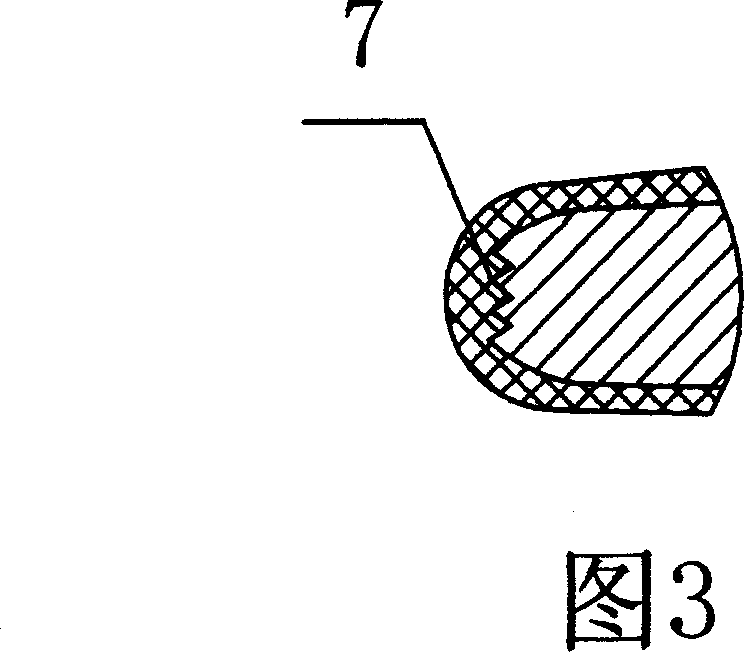

[0037] Embodiment 3: Referring to Figures 3 and 4, as mentioned above, the radial peripheral surface of the valve plate is concaved into serrations 7 or dovetail ring grooves 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com