Preparation method of poly dimethyl allyl ammonium chloride

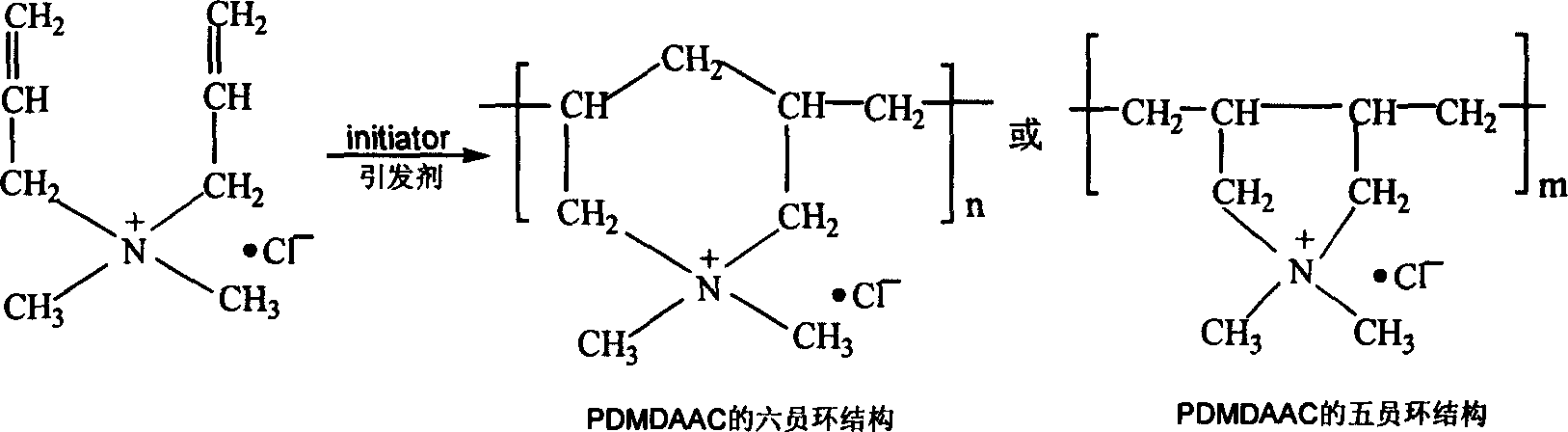

A technology of polydimethyl diallyl ammonium chloride and dimethyl diallyl ammonium chloride is applied in the field of industrial preparation of cationic quaternary ammonium salt homopolymerization products, and can solve the problem of affecting the production cost and production process of PDMDAAC It can not evaluate the economical efficiency of the PDMDAAC preparation process, and cannot explain the problems of the cationic monomer DMDAAC process, so as to achieve the effects of good economy and applicability, low production cost and stable properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

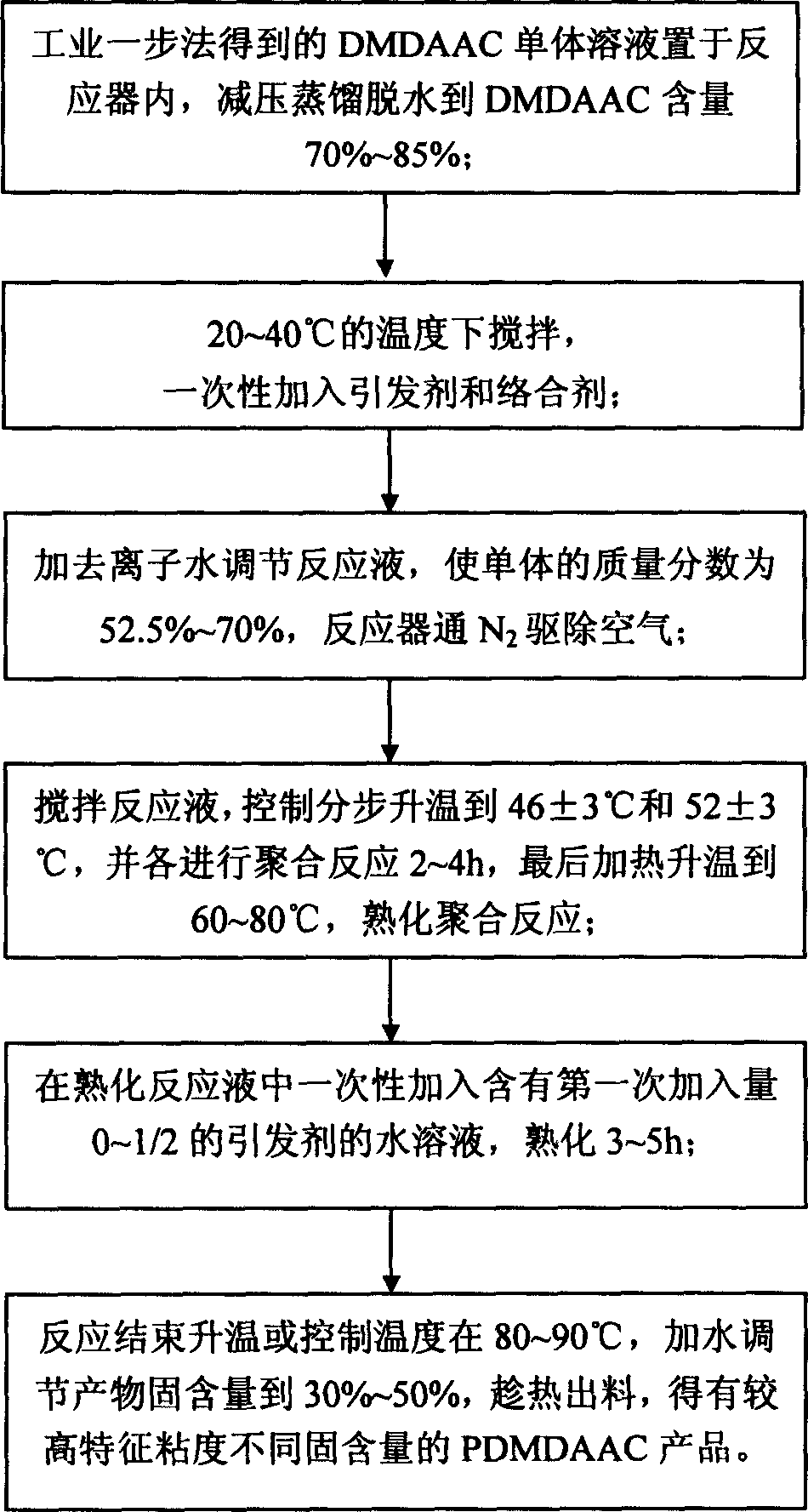

[0046] Embodiment 1: in conjunction with accompanying drawing, the preparation method of polydimethyldiallylammonium chloride of the present invention comprises the following steps:

[0047] In the first step, take 50kg of the monomer solution with a mass fraction of DMDAAC of about 56% prepared by the industrial one-step method, distill and dehydrate it under reduced pressure in the reactor, and obtain 38.9 kg of a monomer solution with a mass fraction of 72.0%;

[0048] In the second step, add the complexing agent Na with stirring at a temperature of 20-40°C. 4 2.0 g of EDTA and 1.0 kg of an aqueous solution of 126 g of initiator ammonium persulfate accounted for about 0.0071% and 0.45% of the mass of the monomer respectively, and were made into a reaction solution;

[0049] In the third step, add 4.8 kg of deionized water, adjust the monomer mass fraction in the reaction solution to 62.5%, and feed nitrogen to remove the air in the reactor;

[0050] The fourth step is to g...

Embodiment 2

[0053] Embodiment 2: in conjunction with accompanying drawing, the preparation method of polydimethyldiallylammonium chloride of the present invention comprises the following steps:

[0054] In the first step, take 50 kg of monomer solution with a mass fraction of DMDAAC of about 56% prepared by an industrial one-step method, distill and dehydrate under reduced pressure in the reactor, and obtain 36.8 kg of a monomer solution with a mass fraction of 76.0%;

[0055] In the second step, the complexing agent Na is dissolved under stirring at a temperature of 20-40°C. 4 2.0 g of EDTA and 1.0 kg of an aqueous solution of 154 g of ammonium persulfate as an initiator, which account for about 0.0071% and 0.55% of the mass of the monomer, respectively, are prepared as a reaction solution;

[0056] In the third step, add 5.1 kg of deionized water, adjust the monomer mass fraction in the reaction solution to be 65.0%, and feed N 2 Remove the air in the reactor;

[0057] Step 4: Under s...

Embodiment 3

[0060] Embodiment 3: in conjunction with accompanying drawing, the specific embodiment of polydimethyldiallyl ammonium chloride preparation method of the present invention is:

[0061] In the first step, take 50 kg of a monomer solution with a mass fraction of DMDAAC of about 56% prepared by an industrial one-step method, distill and dehydrate under reduced pressure in a reactor, and obtain 33.0 kg of a monomer solution with a mass fraction of 85.0%;

[0062] In the second step, the complexing agent Na is dissolved under stirring at a temperature of 20-40°C. 41.0kg of an aqueous solution of EDTA6.0g and initiator potassium persulfate 182g, whose amount accounts for 0.0213% and 0.65% of the monomer mass fraction respectively, is made into a reaction solution;

[0063] In the third step, add 12.5 kg of deionized water, adjust the monomer mass fraction in the reaction to 60.0%, and feed nitrogen to remove the air in the reactor;

[0064] Step 4: Under stirring, gradually increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com