Alloy pole for cobalt antimonides-based thermal electrical part and part making method

A technology of alloy electrodes and thermoelectric elements, applied in the manufacture/processing of thermoelectric devices, thermoelectric device parts, and lead wire materials of thermoelectric device nodes, etc., can solve the problem of high electrical and thermal conductivity, high energy consumption, and oxidation resistance problems such as poor performance, to achieve the effects of reducing thermal stress, good reliability, and good bonding interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

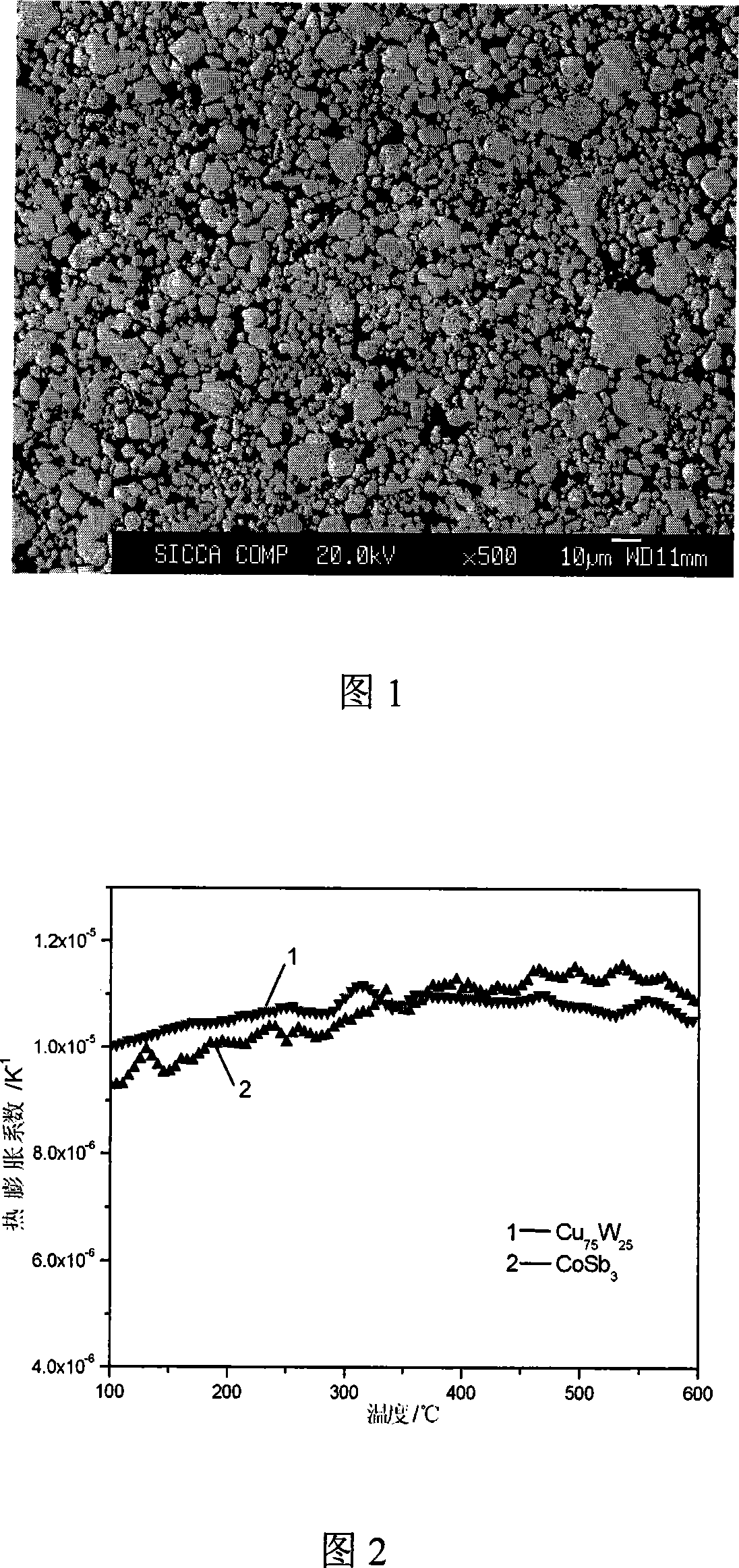

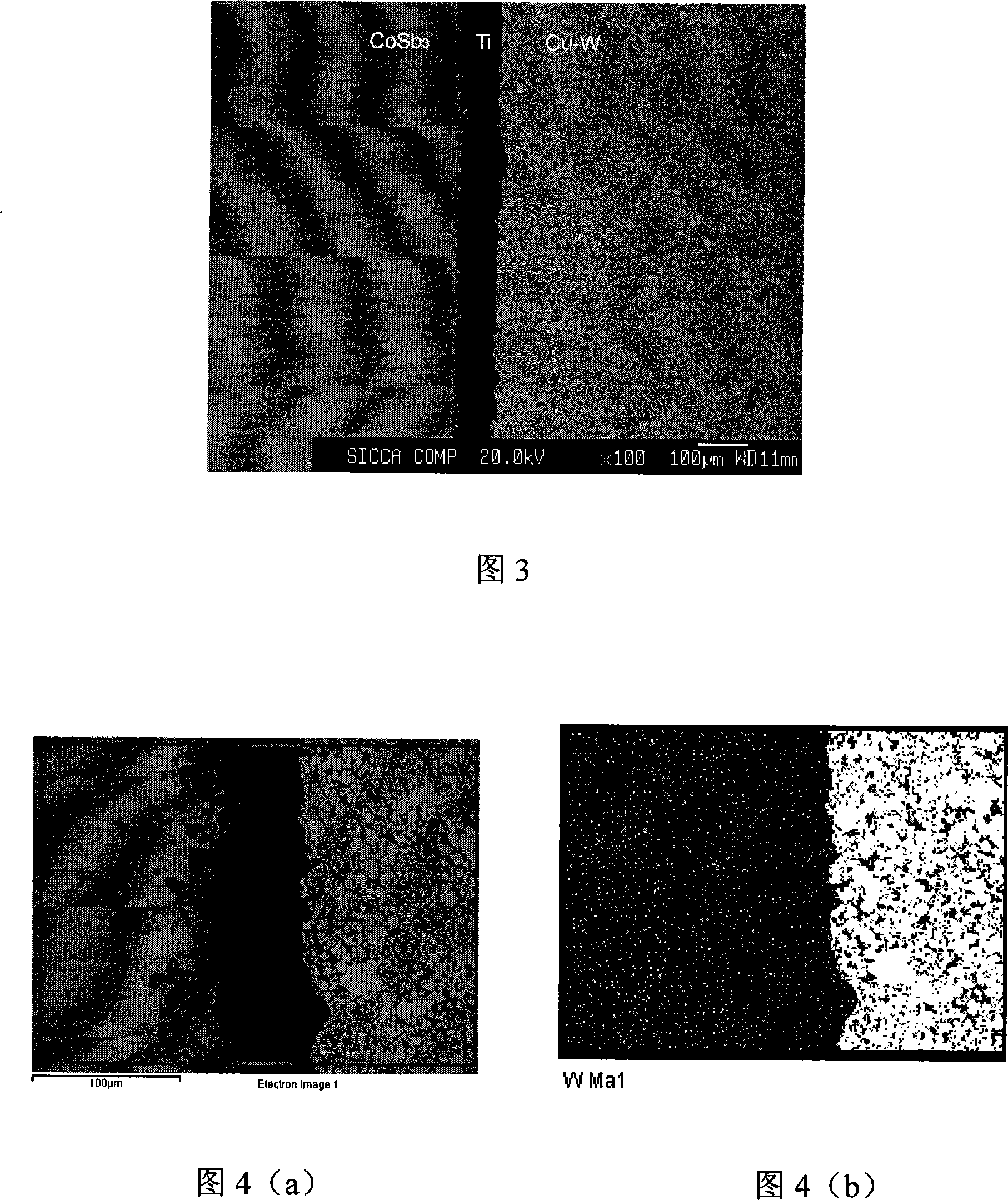

[0016] The copper tungsten electrode is composed of Cu 75 W 25 The thickness is 1mm. The surface is first sandblasted in a sandblasting machine for 2 minutes, and then ultrasonically treated for 10 minutes. Put the copper tungsten electrode into a Φ10 graphite mold, and evenly spread titanium powder with a particle size of 20 μm on the surface of the electrode, and then evenly The cobalt antimonide thermoelectric material is pre-pressed, the pre-pressing pressure is 10MPa, and then SPS sintering is carried out, the vacuum degree is 1Pa, the sintering pressure is 30MPa, the heating rate is 80°C / min, the sintering temperature is 600°C, and then the sintering is completed by holding for 10min.

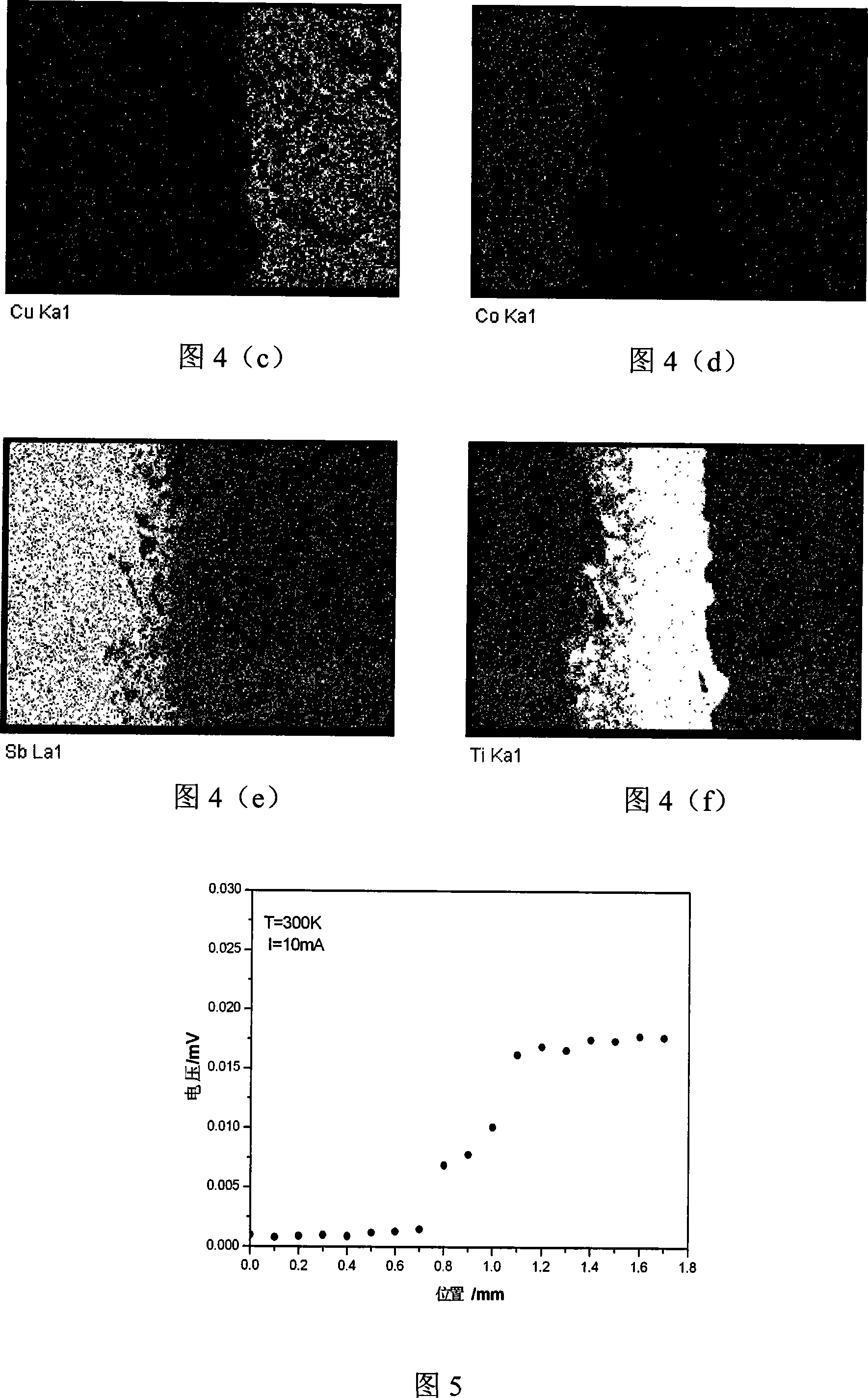

[0017] The resulting Cu-W electrode / CoSb 3 The block was observed by scanning electron microscopy, and the interface was well bonded, with no cracks (see Figure 3). Electron probe analysis showed that there was no obvious interfacial diffusion between the cobalt antimonide-based thermoel...

Embodiment 2

[0019] The copper tungsten electrode component is Cu 80 W 20 The thickness is 2 mm, and the electrode is treated with the same method and conditions as in Example 1. The copper tungsten electrode is placed in a Φ10 graphite mold, and titanium powder with a particle size of 40 μm is evenly spread on the surface of the electrode, and then antimony is evenly pre-pressed For the cobalt-containing thermoelectric material, the pre-compression pressure is 10MPa, and then SPS sintering is carried out, the vacuum degree is 7Pa, the sintering pressure is 50MPa, the heating rate is 120°C / min, the sintering temperature is 580°C, and then the sintering is completed by holding for 20 minutes.

[0020] The resulting Cu-W electrode / CoSb 3No cracks were found in the block after scanning electron microscope observation, and there was no obvious interface diffusion between the cobalt antimonide-based thermoelectric material and the electrode interface by electron probe analysis, and no obvious ...

Embodiment 3

[0022] Copper Tungsten Electrode Cu 70 W 30 The thickness is 3mm, and the electrode is treated with the same method and conditions as in Example 1. The copper tungsten electrode is placed in a Φ10 graphite mold, and titanium powder with a particle size of 50 μm is evenly spread on the surface of the electrode, and then uniformly pre-pressed. Cobalt antimonide thermoelectric material, pre-compression pressure 10MPa, then SPS sintering, vacuum degree 15Pa, sintering pressure 60MPa, heating rate 150 ℃ / min, sintering temperature 550 ℃, and then hold for 30 minutes to complete sintering.

[0023] The resulting Cu-W electrode / CoSb 3 No cracks were found in the block after scanning electron microscope observation, and there was no obvious interface diffusion between the cobalt antimonide-based thermoelectric material and the electrode interface by electron probe analysis, and no obvious potential transition occurred in the interface potential.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com