Complex acid catalyst

A catalyst and composite acid technology, applied in the direction of physical/chemical process catalysts, organic chemistry, chemical recovery, etc., can solve the problems of equipment corrosion, high energy consumption, high catalytic conditions, etc., achieve mild reaction conditions, speed up the reaction speed, and shorten the reaction time the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

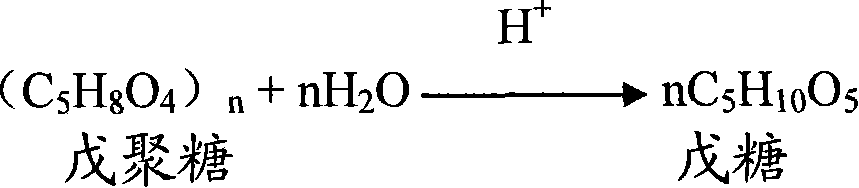

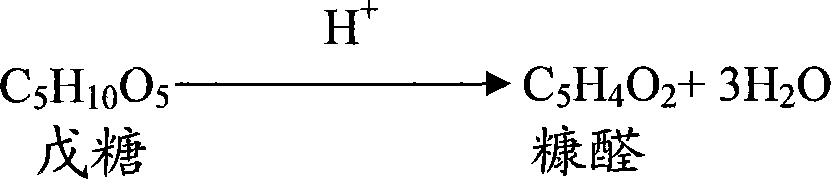

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Monocalcium Phosphate 1%

[0092] Phosphoric acid 25%

[0093] Nitric acid 10%

[0095] Potassium dihydrogen phosphate 2%

[0096] The balance is water.

[0097] Put 100 g of corn cobs cut into 1-2.0 cm and 800 g of the composite acid catalyst solution with the above-mentioned components and contents into a 2L stainless steel hydrolysis reactor for hydrolysis reaction at a reaction temperature of 125°C. After the hydrolysis, the solid-liquid mixture in the hydrolysis reactor is transported to a press for solid-liquid separation, and the obtained pentose hydrolyzate containing the composite acid catalyst is transported to a 1L high-pressure stainless steel dehydration reactor for dehydration reaction , the reaction temperature is 175°C, the obtained aldehyde vapor is condensed into a stock solution through a condenser, and the detection stock solution furfural concentration is 2.64%, and the stock solution quality is 580 grams, promptly ...

Embodiment 2

[0099] Monocalcium Phosphate 15%

[0100] Phosphoric acid 2%

[0101] Nitric acid 10%

[0103] Potassium dihydrogen phosphate 0.1%

[0104] The balance is water.

[0105] Put 100 g of corn cobs cut into 1-2.0 cm and 800 g of the composite acid catalyst solution with the above-mentioned components and contents into a 2L stainless steel hydrolysis reactor for hydrolysis reaction at a reaction temperature of 125°C. After the hydrolysis, the solid-liquid mixture in the hydrolysis reactor is transported to a press for solid-liquid separation, and the obtained pentose hydrolyzate containing the composite acid catalyst is transported to a 1L high-pressure stainless steel dehydration reactor for dehydration reaction , the reaction temperature is 175°C, the obtained aldehyde vapor is condensed into a stock solution through a condenser, and the detection stock solution furfural concentration is 2.8%, and the stock solution quality is 580 grams, namely...

Embodiment 3

[0107] Monocalcium Phosphate 7%

[0108] Phosphoric acid 9%

[0109] Nitric acid 1%

[0111] Potassium dihydrogen phosphate 1.8%

[0112] The balance is water.

[0113] Put 100 g of corn cobs cut into 1-2.0 cm and 800 g of the composite acid catalyst solution with the above-mentioned components and contents into a 2L stainless steel hydrolysis reactor for hydrolysis reaction at a reaction temperature of 125°C. After the hydrolysis, the solid-liquid mixture in the hydrolysis reactor is transported to a press for solid-liquid separation, and the obtained pentose hydrolyzate containing the composite acid catalyst is transported to a 1L high-pressure stainless steel dehydration reactor for dehydration reaction , the reaction temperature is 175°C, the obtained aldehyde vapor is condensed into a stock solution through a condenser, and the concentration of the furfural in the stock solution is 2.9%, and the mass of the stock solution is 580 grams, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com