Method for manufacturing cuprous thiocyanate membrane in liquid phase condition

A technology of cuprous thiocyanate and thiocyanate, applied in thiocyanic acid, chemical instruments and methods, solutions of liquid solvents at room temperature, etc., can solve the problems of slow film growth rate, film deposition failure, etc., and achieve stability Good, reduce production energy consumption, improve the effect of growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

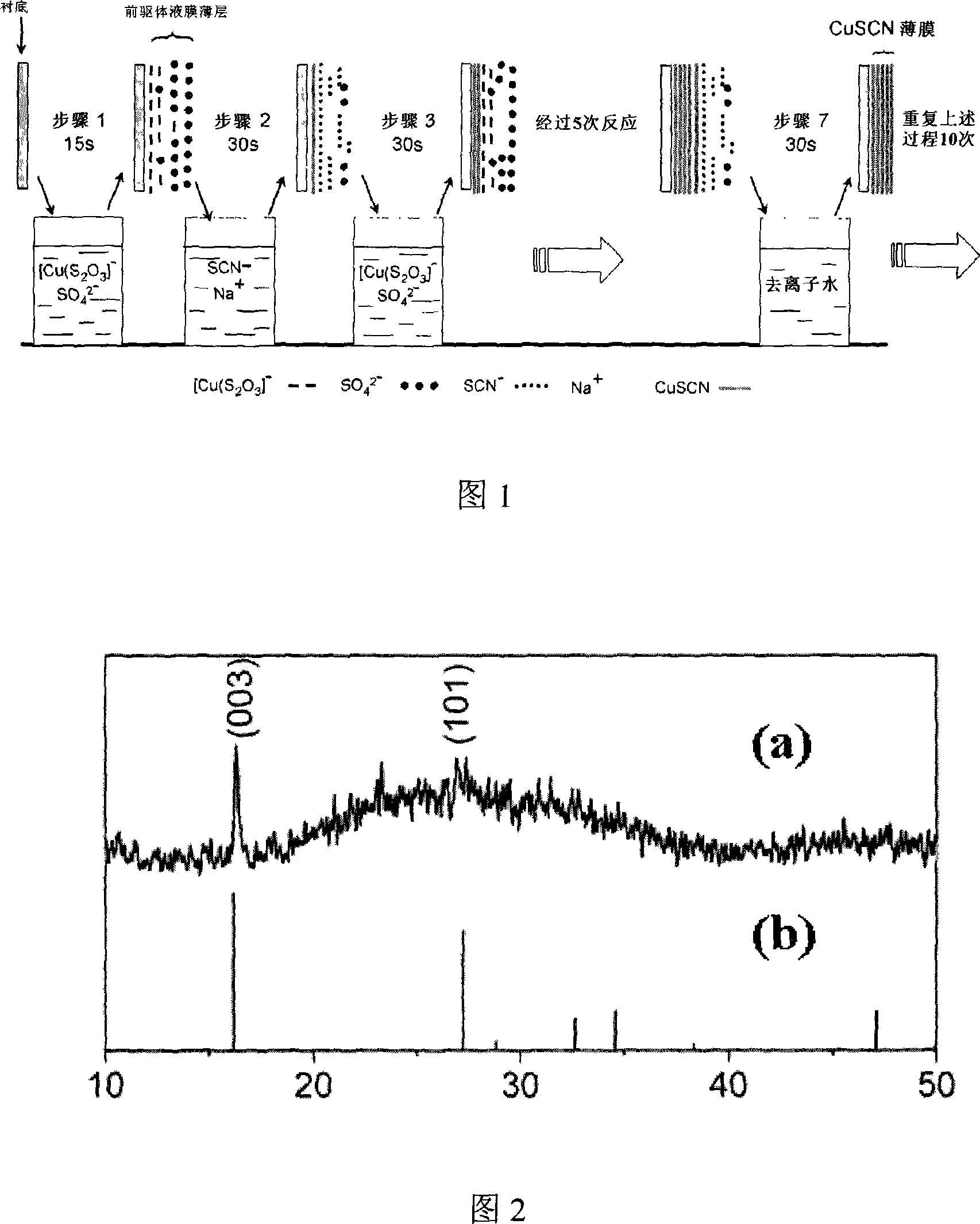

Method used

Image

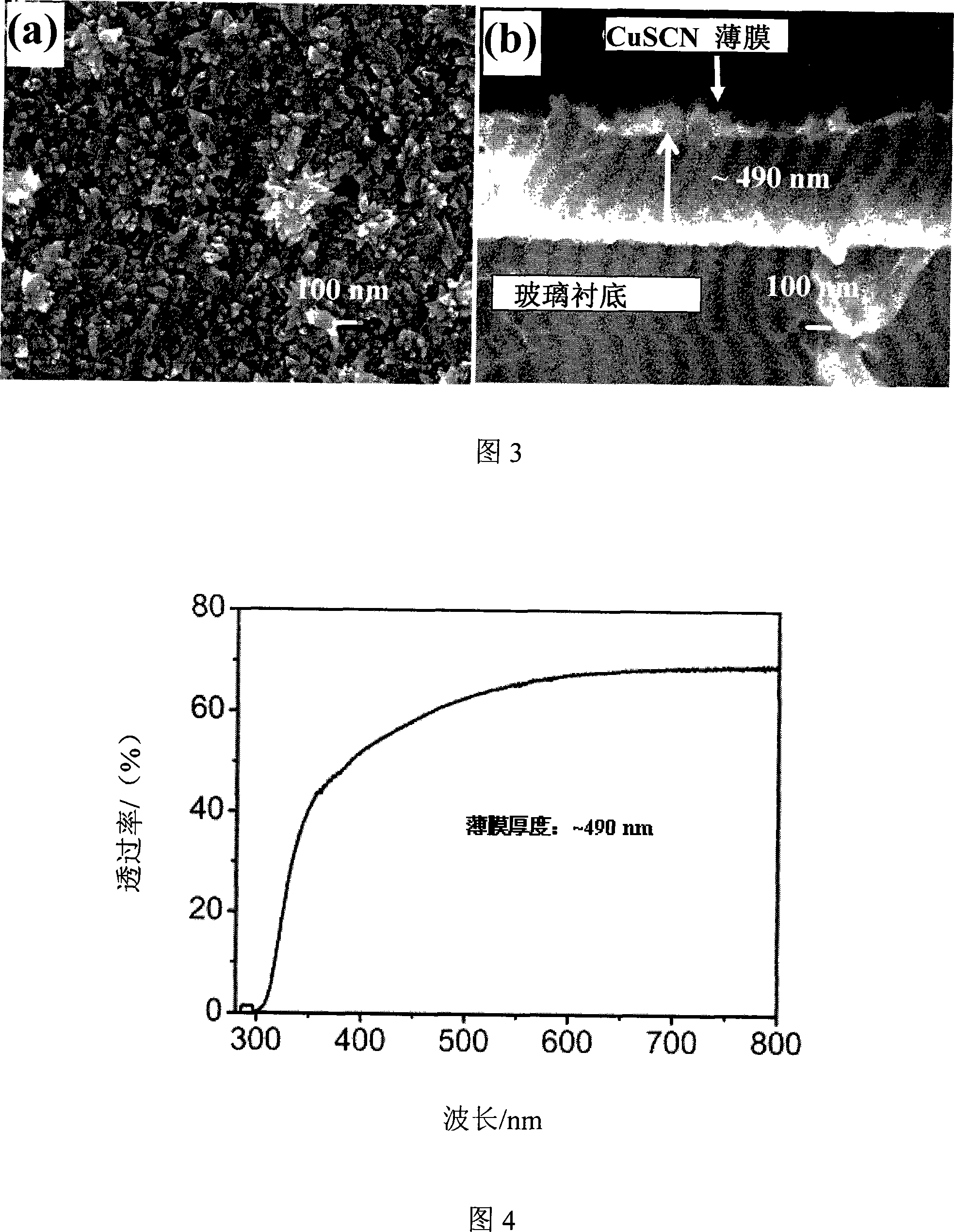

Examples

Embodiment 1

[0032] 1. Preparation of precursor solution:

[0033] Copper source precursor: weigh copper sulfate (CuSO4 .5H 2 (O) 0.25g, be dissolved in 50ml deionized water, add sodium thiosulfate (Na 2 S 2 o 3 )0.744g, fully stirred and dissolved to obtain [Cu(S 2 o 3 )] - Complex solution, copper ion concentration in the copper source precursor is 0.002mol / L, Na 2 S 2 o 3 The concentration is 0.006mol / L, and the molar concentration ratio of complexing agent to copper ion is 3;

[0034] Thiocyanate precursor: Weigh 0.0253g of sodium thiocyanate (NaSCN) and dissolve it in 50ml of deionized water to obtain a NaSCN precursor solution with a concentration of 0.025mol / L;

[0035] 2. Substrate preparation.

[0036] Ordinary glass is used as the substrate, and the cleaning process is as follows: firstly, it is etched and cleaned with hot dilute sulfuric acid (about 60°C) for 30 minutes; then it is fully rinsed with acetone, ethanol and deionized water, preferably Blow dry with Ar flo...

Embodiment 2

[0050] 1. Preparation of precursor solution:

[0051] Copper source precursor: weigh copper sulfate (CuSO 4 .5H 2 (O) 2.5g, be dissolved in 50ml deionized water, add sodium thiosulfate (Na 2 S 2 o 3 )7.44g, fully stirred and dissolved to obtain [Cu(S 2 o 3 )] - complex solution. Thiocyanate precursor: Weigh 2.53g of sodium thiocyanate (NaSCN) and dissolve it in 50ml of deionized water to obtain a NaSCN precursor solution.

[0052] 2. Substrate preparation.

[0053] Select a single crystal silicon wafer (111) as the substrate, and the cleaning process is as follows: first, wash with 1:1 hydrofluoric acid for 10 minutes to remove the surface oxide layer, then rinse with acetone, ethanol and deionized water in sequence, preferably with Air-dried with Ar, placed in a desiccator for later use.

[0054] 3. Film growth.

[0055] b. Transfer the substrate to the NaSCN precursor solution, so that the [Cu(S 2 o 3 )] - with SCN - response, and perform SCN - The adsorption...

Embodiment 3

[0061] Using copper chloride or copper nitrate as the copper source, potassium thiosulfate as the thiocyanate precursor, and sapphire as the substrate, the process steps are the same as in Examples 1 and 2, and the results are also similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com