Siliceous alkynes fragrant polytriazoles resin and method for making same

A polytriazole resin and polytriazole technology, which is applied in the field of silicon-containing aromatic polytriazole resin and its preparation, can solve the problems of high brittleness of silicon-containing aryne resin and unsatisfactory adhesion between resin and fiber, etc. Achieve excellent physical and mechanical properties and thermal properties, high glass transition temperature, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

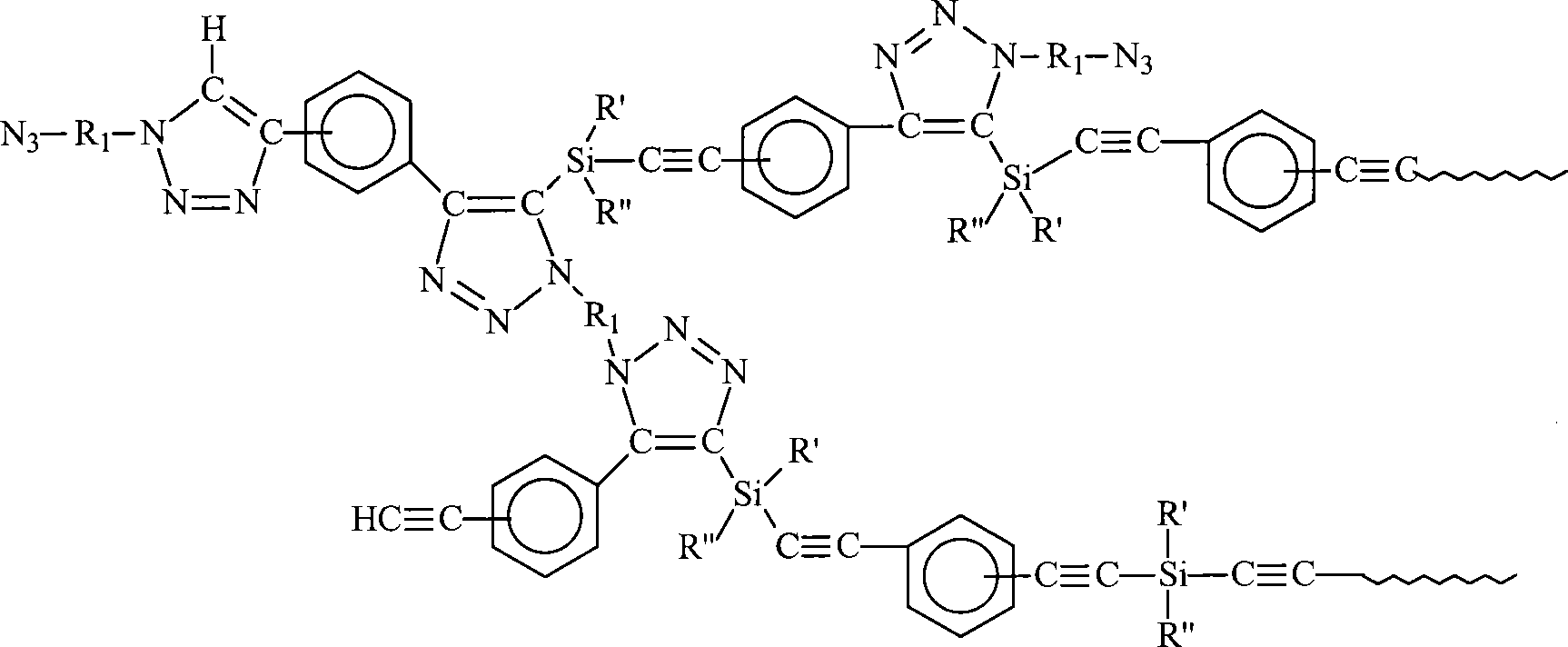

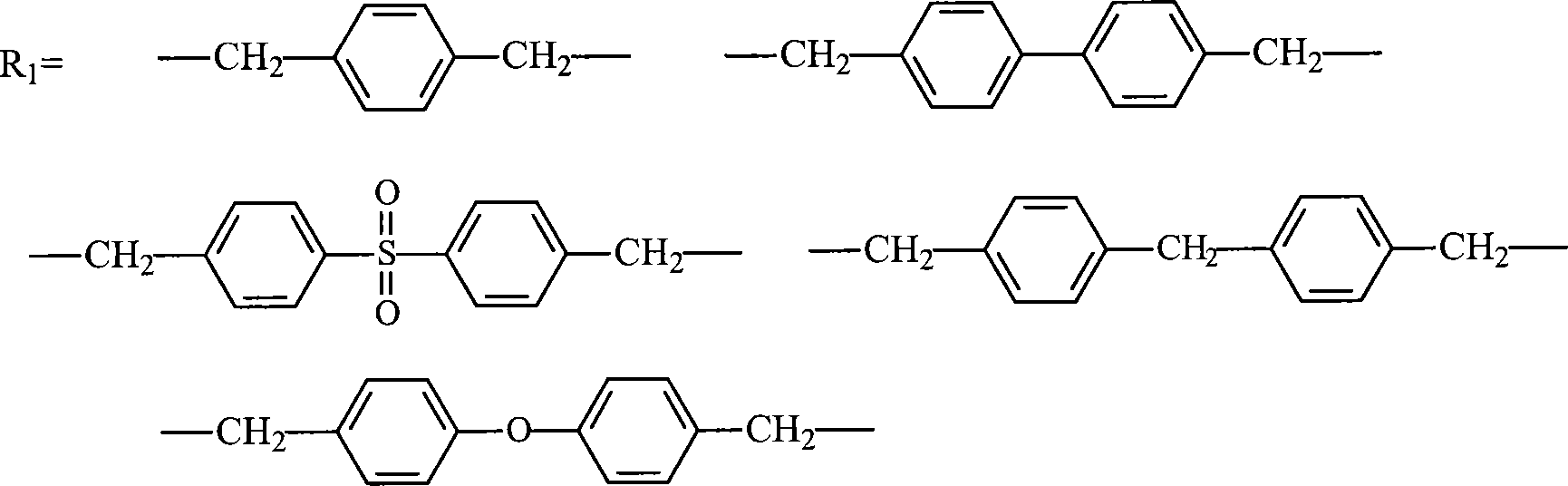

[0050] Example 1 Preparation of dimethyl-type silyne-containing aromatic polytriazole resin (A1-1)

[0051] 1. Synthesis of 4,4'-diazidemethylbiphenyl

[0052] Add 12.55 g (0.05 mol) of p-dichloromethylbiphenyl, NaN 3 9.75g (0.15mol), benzene (20ml) and DMF (20ml), heated to 70~75°C under stirring, and reacted at constant temperature for 3h. After the reaction, cooled the reaction product to room temperature, poured it into 200ml deionized water, and let it stand Overnight, a white solid was precipitated, filtered, the filter cake was washed with deionized water, and dried to obtain a white powdery solid with a yield of 89.0% and a melting point of 67-71°C.

[0053] 2. Synthesis of dimethyl-type silicon-containing aryne resin

[0054] Add treated 6.00g (0.247mol) magnesium powder and 50ml THF into a 250ml four-neck flask equipped with a stirring, constant pressure funnel and spherical condenser, and then slowly add 21.6g (0.198mol) of magnesium powder dropwise through the c...

Embodiment 2

[0060]Example 2 Preparation of dimethyl-type silyne-containing aromatic polytriazole resin (A1-2)

[0061] The preparation of 4,4'-diazidemethylbiphenyl and dimethyl type silicon-containing aryne resin is the same as in Example 1.

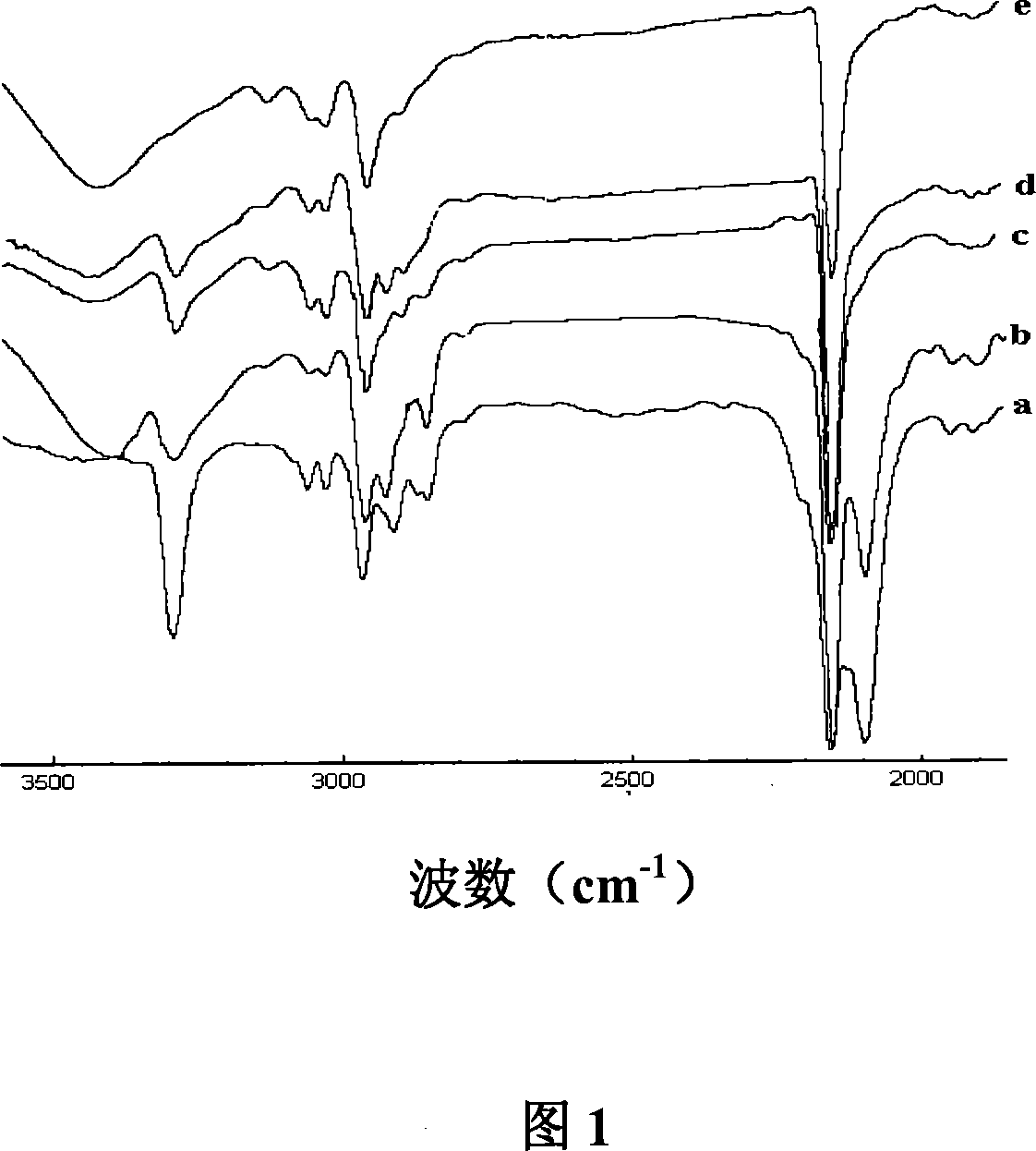

[0062] Add 3.96g of 4,4'-diazidemethylbiphenyl (0.015mol of azide group, 0.030mol), 5.48g of dimethyl type silicon-containing aryne resin (0.0073mol, 0.065mol of alkynyl group) and 30ml of THF In the reactor, the reaction was stirred under reflux for 2 h, and finally the solvent was removed to obtain a reddish-brown solid resin. In the range of 70-110°C, the viscosity of the resin is 0.7Pa.s; when the temperature is higher than 120°C, the viscosity rises rapidly and begins to gel. Infrared spectrum: 3300cm -1 There is a ≡C-H vibration peak at 2098cm -1 and 2156cm -1 -N=N=N and C≡C vibrational absorption peaks appear at about 3140cm -1 The C-H vibrational absorption peak on the triazole ring appears.

[0063] The resin was cured at 80°C / 12h, 1...

Embodiment 3

[0064] Example 3 Preparation of dimethyl-type silyne-containing aromatic polytriazole resin (A1-3)

[0065] The preparation of 4,4'-diazidemethylbiphenyl and dimethyl type silicon-containing aryne resin is the same as in Example 1.

[0066] Add 3.96g (0.015mol, azide group 0.030mol) of 4,4'-diazidemethylbiphenyl and 5.48g (0.0073mol, alkynyl group 0.065mol) of dimethyl type silicon-containing aryne resin into the reactor , the reaction was stirred at 80° C. for 0.5 h to obtain a reddish-brown solid resin. In the range of 70-110°C, the viscosity of the resin is 0.9 Pa.s; when the temperature is higher than 120°C, the viscosity rises rapidly and begins to gel. Infrared spectrum: 3300cm -1 There is a ≡C-H vibration peak at 2098cm -1 and 2156cm -1 -N=N=N and C≡C vibrational absorption peaks appear at about 3150cm -1 The C-H vibrational absorption peak on the triazole ring appears.

[0067] The resin was cured at 80°C / 12h, 120°C / 2h, 150°C / 2h, 170°C / 2h, 210°C / 2h, and post-trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com