Method for preparing hydroxyapatite nano composite coat with gradient function

A nano-composite coating and hydroxyapatite technology, which is applied in the direction of coating, electrolytic coating, electrophoretic plating, etc., can solve the problems of harmful coating and easy peeling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

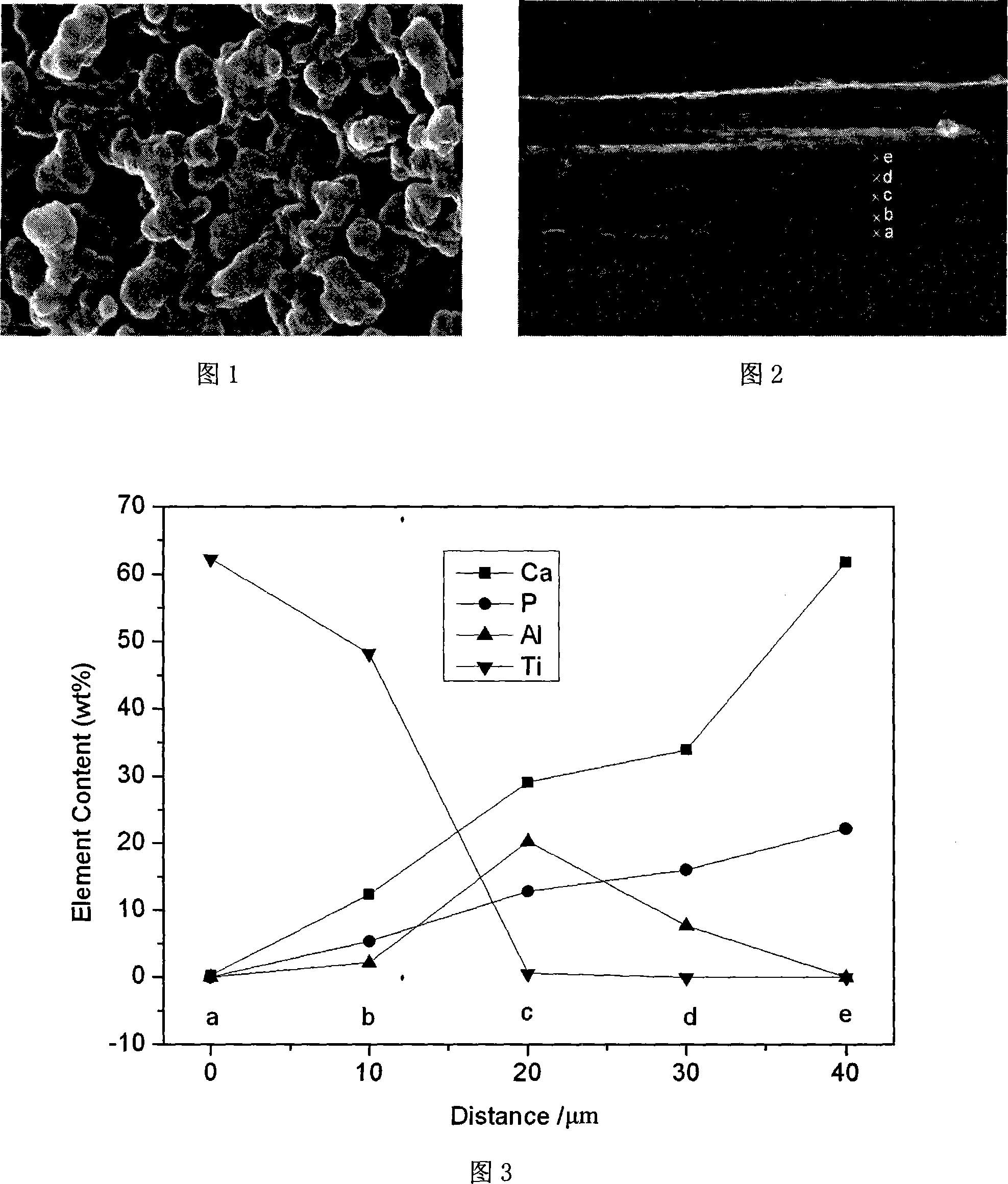

Embodiment 1

[0024] 1. Substrate pretreatment: (1) Mechanical polishing: Take a titanium sample with a thickness of 0.8mm and cut it into a sample with a size of about 30mm×10mm, and then mechanically polish it with 100#, 800#, 1200# water-grinding sandpaper until the surface is uniform bright. (2) Alkali elution means: add 10g sodium carbonate, 10g sodium phosphate, and 5g sodium silicate in 500mL deionized water in sequence, heat to dissolve, then add 2.5mL polyethylene glycol octylphenyl ether (OP-10 ),well mixed. Pour out about 50mL, put all the polished titanium samples into the alkaline washing solution, boil for 5min, then transfer to an ultrasonic cleaner and sonicate for 5min. After taking it out, rinse it with tap water to completely remove the residual lye on the surface. (3) Acid etching: first add a certain amount of deionized water to a graduated 500mL plastic bottle, then add 50mL HF (40wt%) and 150mL concentrated HNO 3 (68wt%), shake well, add deionized water to the 500m...

Embodiment 2

[0031] 1. Substrate pretreatment: (1) Mechanical polishing: Same as in Example 1. (2) Alkali elution means: same as embodiment 1. (3) Acid etching: first add a certain amount of deionized water to a graduated 500mL plastic bottle, then add 40mL HF (40wt%) and 120mL concentrated HNO 3 (68wt%), shake well, add deionized water to the 500mL mark, shake well. Pour out about 50mL into a plastic beaker, put the titanium samples after alkali washing into the treatment one by one, and the treatment time is about 40s. Clean and dry in an oven at 120°C for later use.

[0032] 2. Suspension preparation: Suspension was prepared according to Example 1, and left to age for 2 days.

[0033] 3. Electrophoretic deposition: Before deposition, the suspension was stirred and ultrasonicated for 25 minutes, and two stainless steel counter electrodes (3.5cm×4cm×0.06cm) were inserted into the S1, S2 and S3 suspensions in parallel, and the distance between them was adjusted to 2cm. Insert the pretr...

Embodiment 3

[0037] 1. Substrate pretreatment: (1) Mechanical polishing: replace titanium with TC4 titanium alloy, and the rest are the same as in Example 1. (2) Alkali elution refers to: add 7.5g sodium carbonate, 7.5g sodium phosphate, 2.5g sodium silicate in 500mL deionized water in sequence, heat to dissolve, then add 2mL polyethylene glycol octylphenyl ether (OP -10), mix well. Pour out about 50mL, put all the polished titanium samples into the alkali washing solution, boil for 5 minutes, then transfer to an ultrasonic cleaner for 5 minutes of ultrasonic cleaning. After taking it out, rinse it with tap water to completely remove the residual alkali solution on the surface. (3) acid etching: with embodiment 1.

[0038] 3. Preparation of suspension: Measure 50mL of absolute ethanol in a 100mL beaker, add 1 drop of concentrated HNO 3 , after stirring, use pH test paper to test that the pH is between 4 and 5, add different ratios of HAp powder and Al powder, and prepare three suspension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com