Chitosan quaternary ammonium salt, preparing method and application of the same

The technology of chitosan quaternary ammonium salt and quaternary ammonium salt is applied in the field of chitosan quaternary ammonium salt and its preparation, which can solve the problems of skin irritation, product viscosity decrease, limited application and the like, and achieves significant bacteriostatic activity, Low cost, delayed cell damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation method of chitosan quaternary ammonium salt (HHACC) and chitosan quaternary ammonium salt (LHACC):

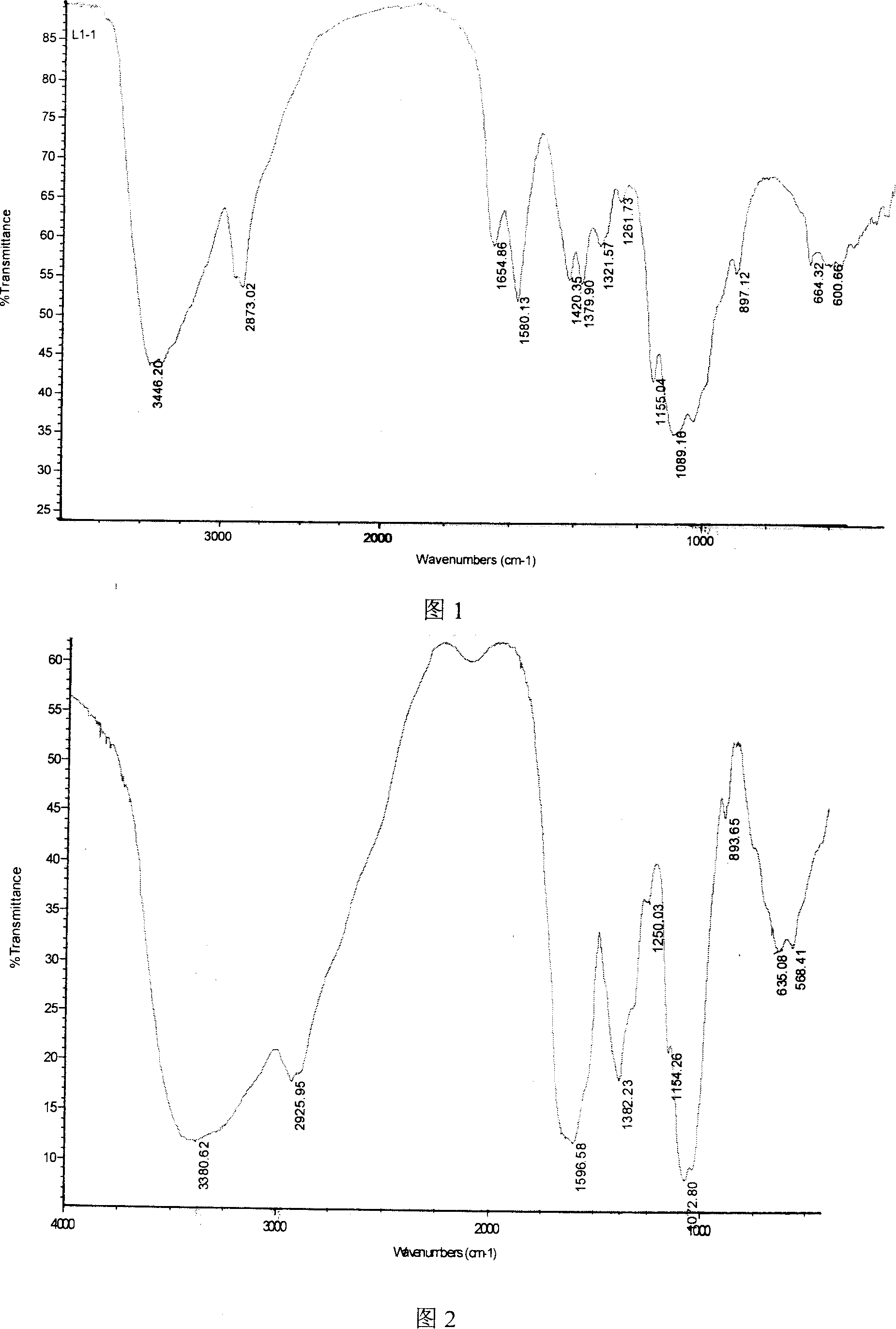

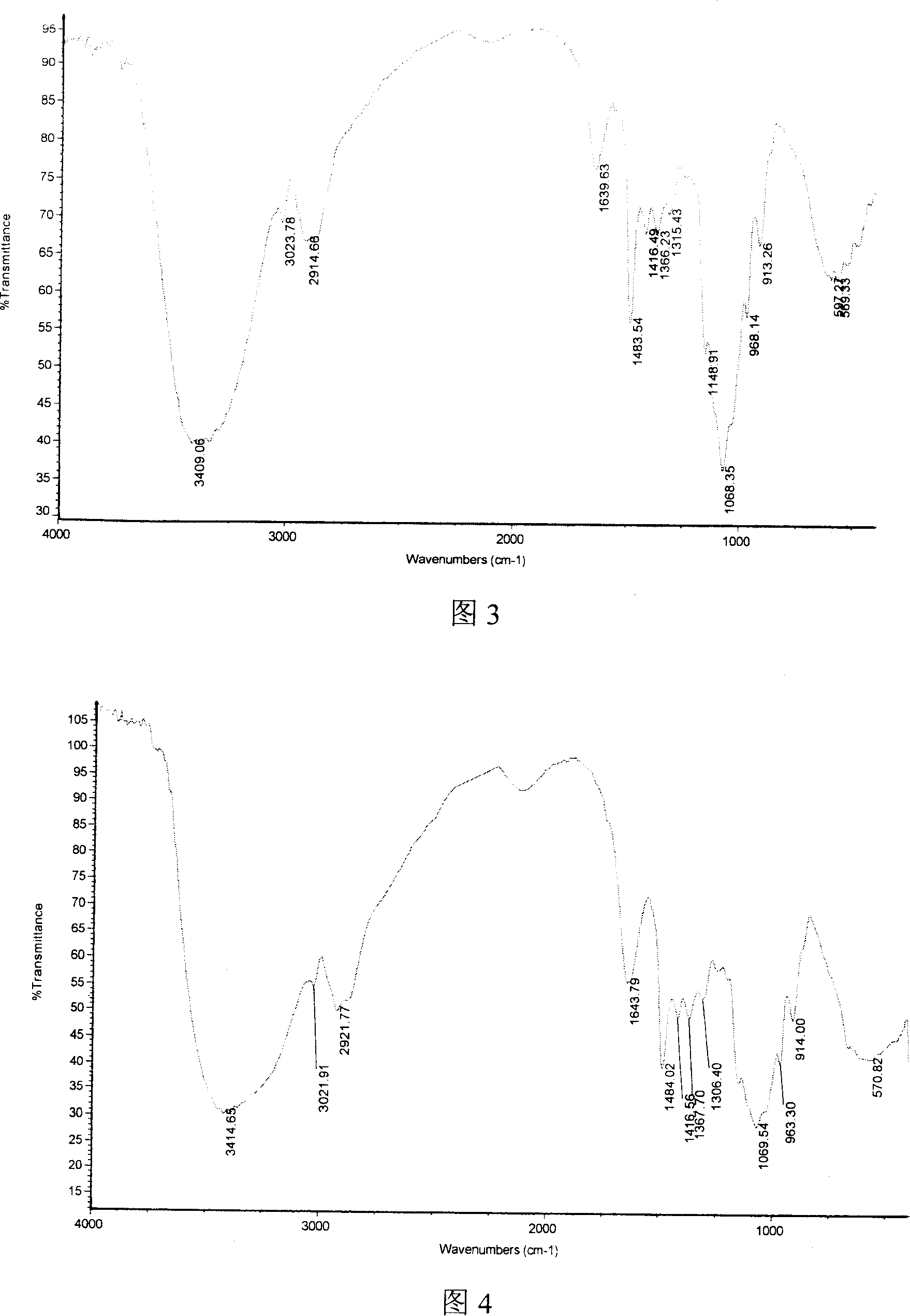

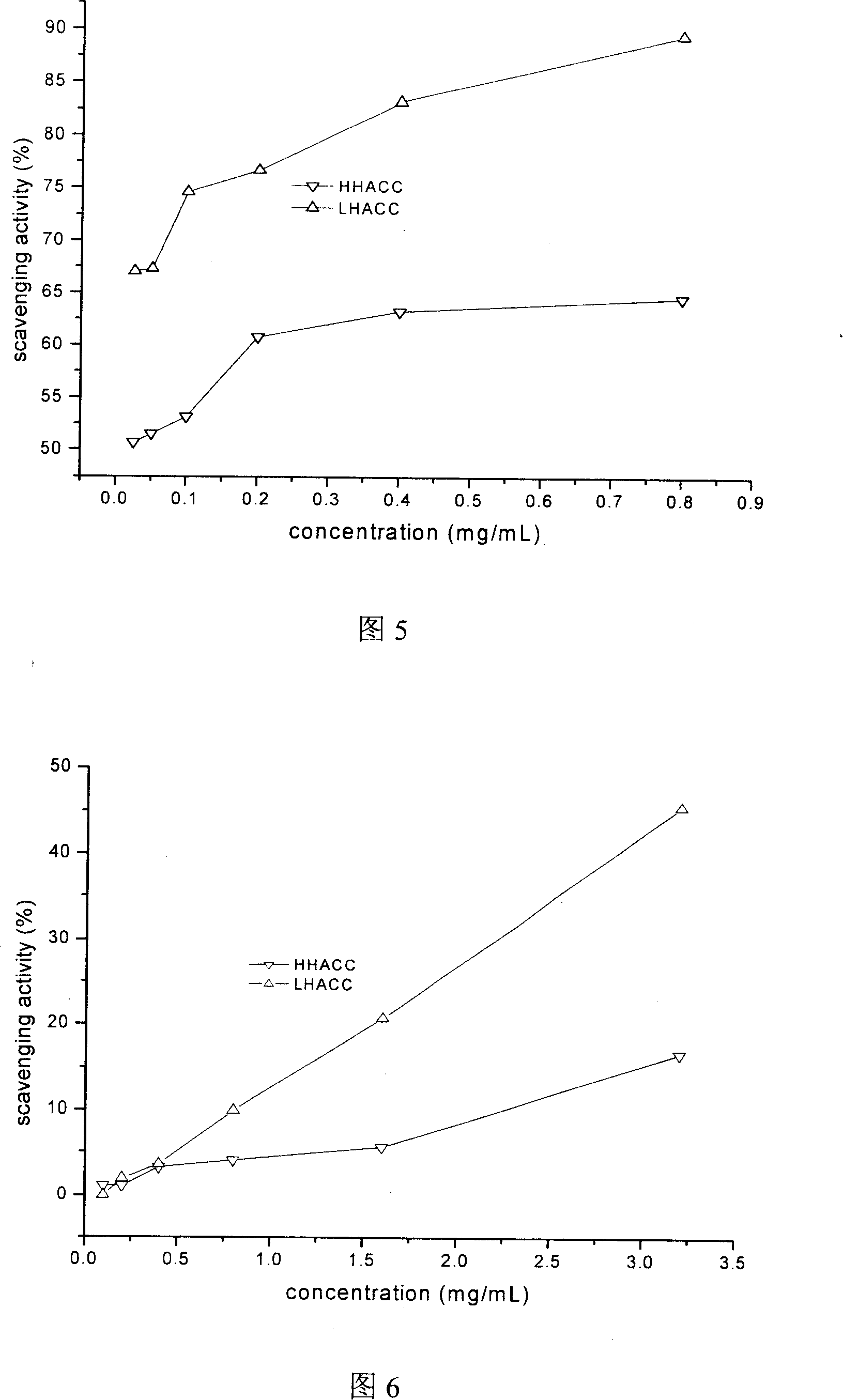

[0045] 1) Weigh 5g molecular weight as 5.0×10 5 The chitosan powder of D (see Figure 1) or 5 g of chitosan powder with a molecular weight of 8000D; wherein: the chitosan oligosaccharide (see Figure 2) is prepared by the microwave action method, see the microwave-degraded chitosan compound and its preparation The patent of the method, the patent number is 03138817.5.

[0046] 2) adding distilled water to the weighed chitosan, the amount of which is 10 times the weight and volume of the chitosan, and heating to 60° C. under stirring;

[0047] 3) to the solution of step 2), add the isopropanol of 4g and the glycidyl trimethyl ammonium chloride of 3 times the molar weight of chitosan powder, react after 3 hours for standby, the product is white, soluble small particles;

[0048] 4) Adjust the reaction solution in step 3) with HCl to make its pH value 5.5;

[0...

Embodiment 2

[0080] 1) Weigh 5g molecular weight as 5.0×10 5 D chitosan powder or 5g molecular weight 8000D oligosaccharide powder;

[0081] 2) adding distilled water to the weighed chitosan, the amount of the distilled water being 12 times the weight and volume of the chitosan, and heating up to 65°C under stirring;

[0082] 3) to the solution of step 2), add isopropanol with 3 times of chitosan powder volume weight and glycidyl trimethyl ammonium chloride with 4 times of chitosan powder molar weight, react after 5 hours for standby, the product is white, Insoluble cotton wool;

[0083] 4) Adjust the reaction solution in step 3) with HCl to make its pH value 5.5;

[0084] 5) using distilled water for the reaction solution with a pH value of 5.5 in step 4), dialysis by a dialysis bag with a molecular weight cut-off of 8000, and concentrating after the dialysis;

[0085] 6) Precipitate the concentrated solution with acetone after concentration, separate out white and / or yellow precipitat...

Embodiment 3

[0089] 1) Weigh 5g molecular weight as 5.0×10 5 D chitosan powder or 5g molecular weight 8000D oligosaccharide powder;

[0090] 2) adding distilled water to the weighed chitosan, the amount of the distilled water being 12 times the weight and volume of the chitosan, and heating up to 70°C under stirring;

[0091] 3) to the solution of step 2), add isopropanol with 3 times of chitosan powder volume weight and glycidyl trimethylammonium chloride with 4 times of chitosan powder molar weight, react after 4 hours for standby, the product is white, Insoluble cotton wool;

[0092] 4) Adjust the reaction solution in step 3) with HCl to make its pH value 5.5;

[0093] 5) using distilled water for the reaction solution with a pH value of 5.5 in step 4), dialysis by a dialysis bag with a molecular weight cut-off of 8000, and concentrating after the dialysis;

[0094] 6) Precipitate the concentrated solution with acetone after concentration, separate out white and / or yellow precipitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com